Fluoelectrolysis reactor and reaction method

An electrolysis reaction and reactor technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as affecting production safety, corrosive liquid leakage, etc., and achieve a stable electrolysis reaction environment, improve productivity, and expand the scope of use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Preferred embodiments of the present invention are described in detail below.

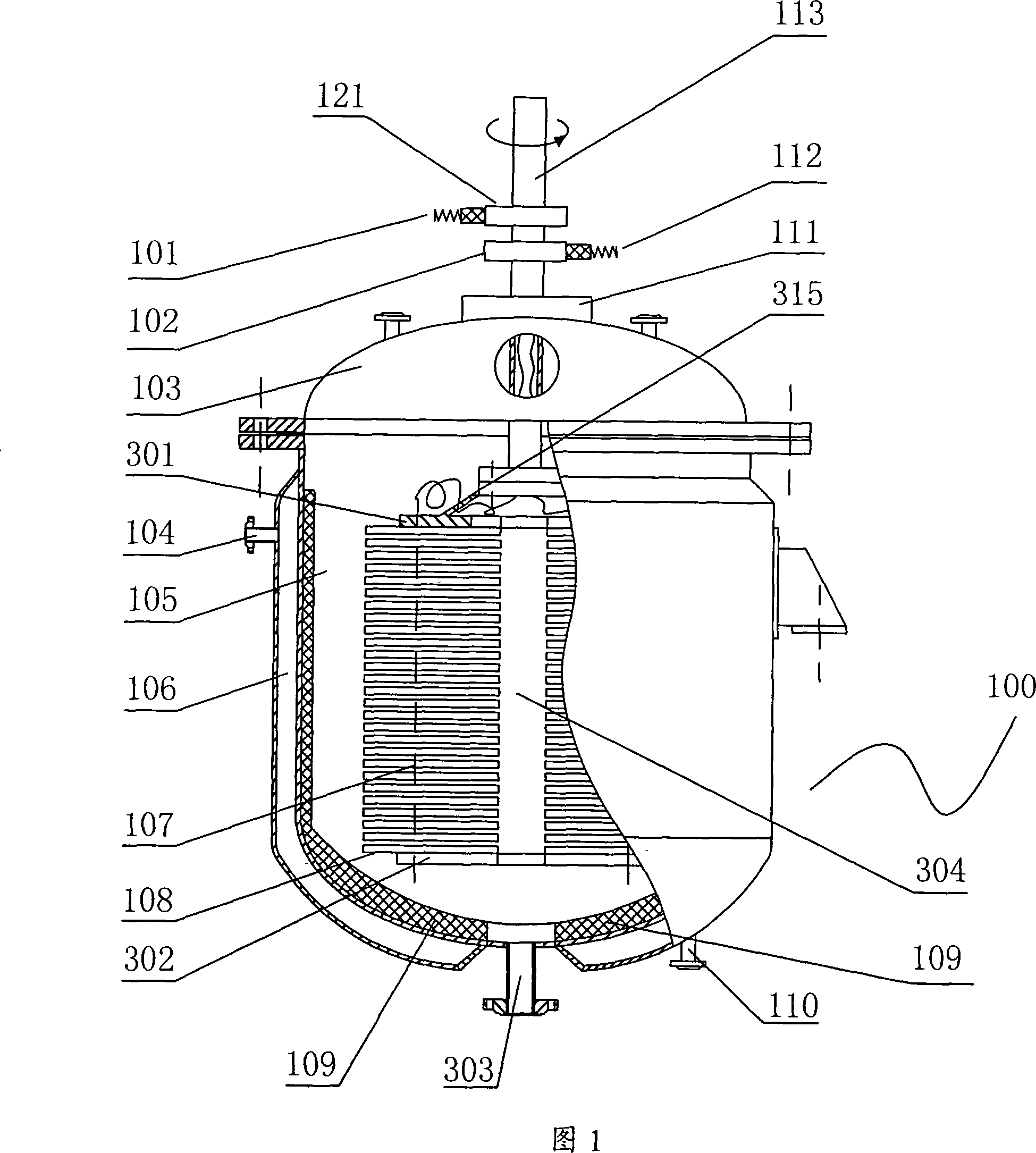

[0031] As shown in Figure 1, the present invention provides a reactor 100 for fluorination electrolysis, which includes an electrolysis reactor 105, on which a kettle cover 103 is provided for sealing the reactor 105, and a sealing device 111 can also be provided To ensure the dynamic sealing state of the reactor, for enhancing the degree of safety; the reactor 100 also includes at least one pair of electrode plates 108, a pair of positive and negative electrode leads; and, the electrolysis reactor 105 is also provided with a cooling jacket 106, used For cooling the reactor, the cooling jacket 106 can adopt a liquid cooling method, specifically, the inflow and outflow of cooling liquid or circulating cooling can be realized through the input pipe 104 and the output pipe 110 .

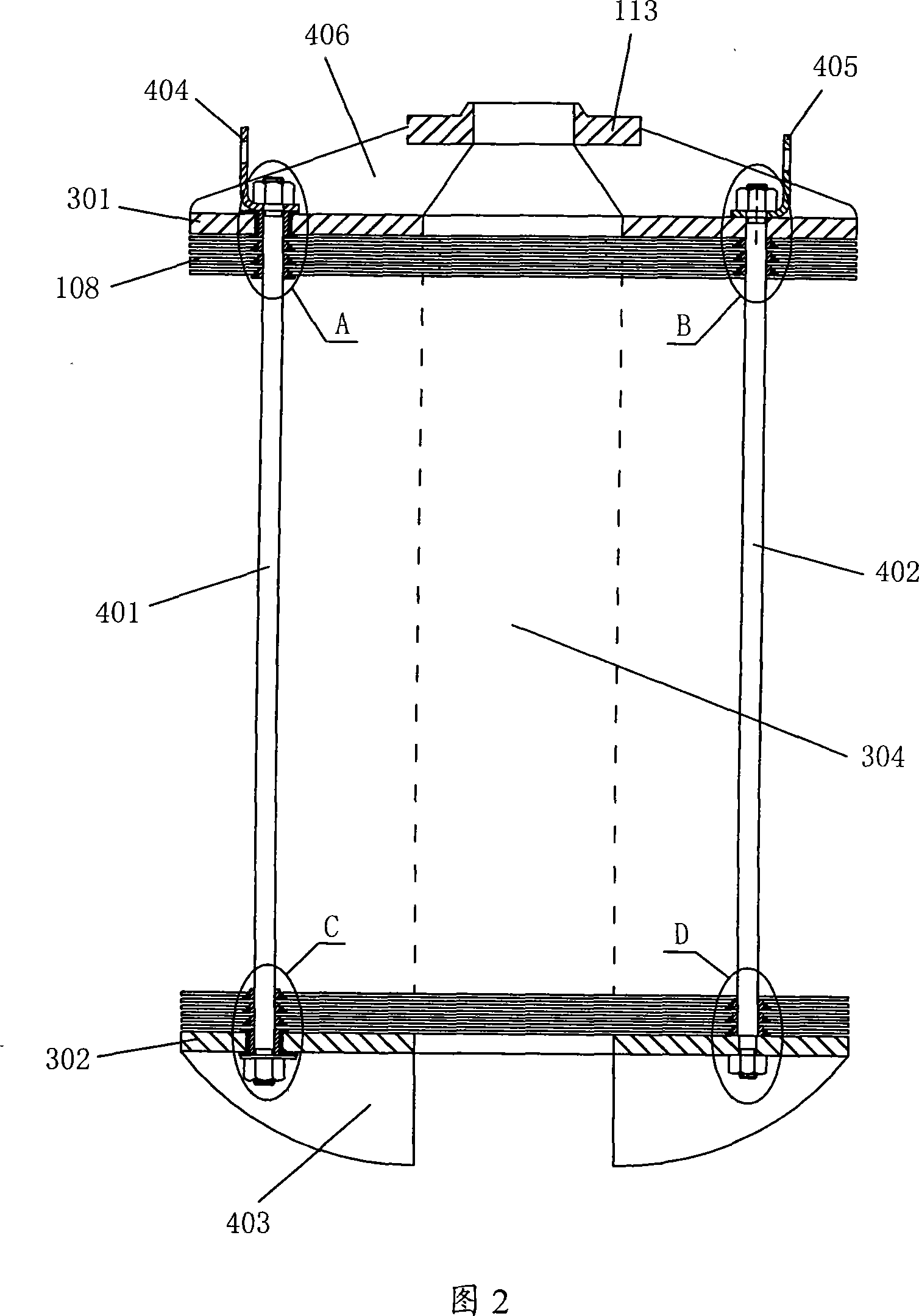

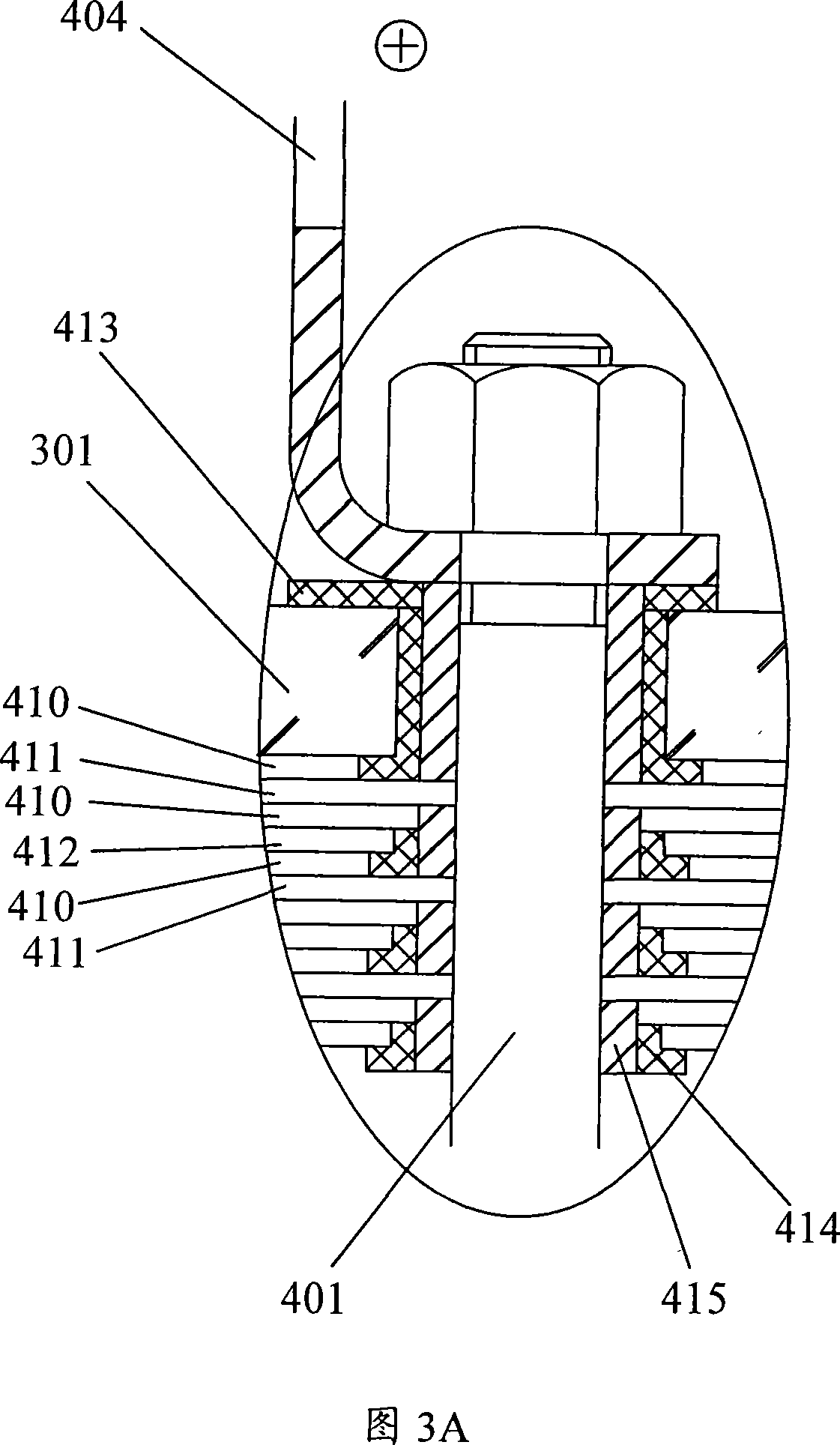

[0032] The reactor also includes at least one pair of cathode and anode positioning screws 107, an upper splint 301...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com