Paint feeding machine for building wall surface spraying

A technology for walls and coatings, applied in mixers, mixer accessories, shaker/oscillation/vibration mixers, etc., can solve problems such as uneven distribution of media and easy agglomeration, and achieve the effect of ensuring the quality of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

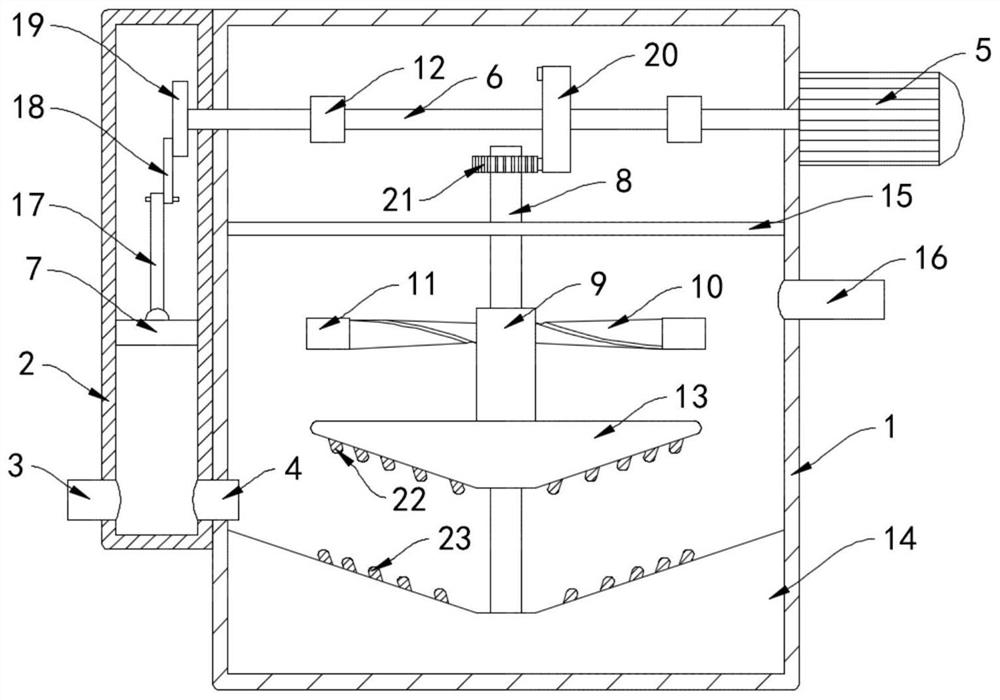

[0021] Such as Figure 1-2 As shown, a paint feeder for building wall surface spraying includes a housing 1, a feed box 2 is installed on the side wall of the housing 1, and a one-way feed pipe 3 is installed on the side wall of the feed box 2 , the one-way feed pipe 3 only allows the external paint to enter the feed box 2, and the feed box 2 communicates with the housing 1 through the one-way communication pipe 4, and the one-way communication pipe 4 only allows paint to enter the housing from the feed box 2 1, a horizontally arranged sealing plate 15 is installed in the housing 1, and the sealing plate 15 plays a role of sealing and isolating the paint. The evenly stirred paint in the inner and upper layers can be discharged into the sprayer through the discharge pipe 16 .

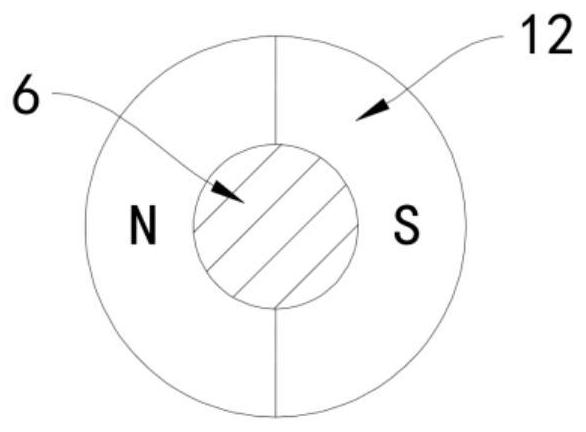

[0022] Drive motor 5 is installed on the side wall of housing 1, and drive motor 5 is a servo motor. During work, control drive motor 5 runs at a slower speed of 180r / min, and the output shaft of drive ...

Embodiment 2

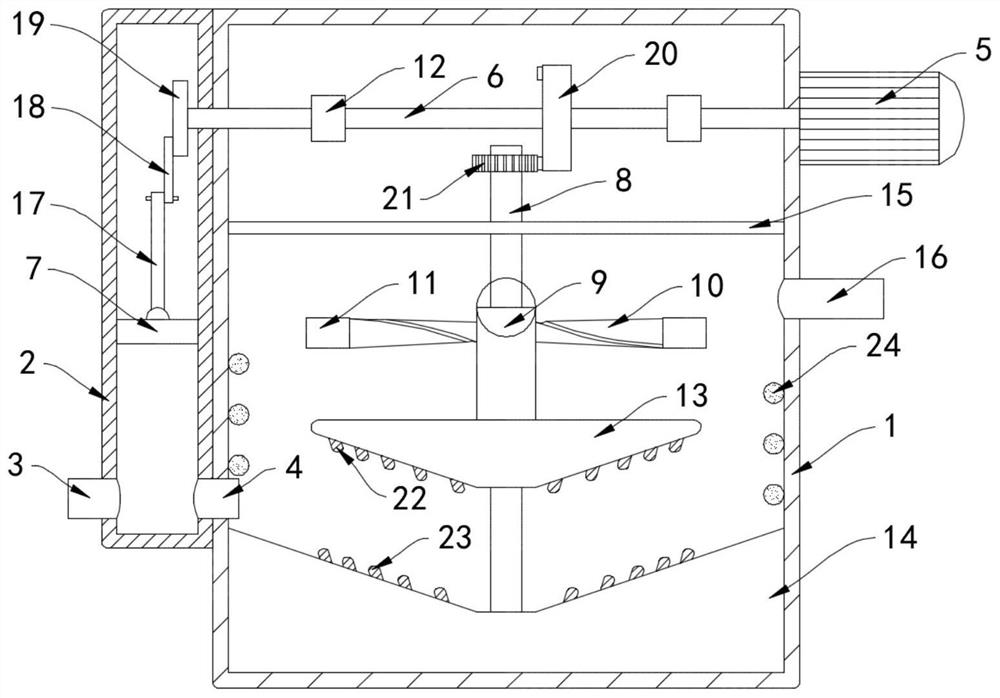

[0030] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that an electromagnetic spring 24 is wound on the inner wall of the housing 1, and the head and tail ends of the electromagnetic spring 24 are electrically connected to form a closed loop, and the lower end of the electromagnetic spring 24 is connected to the grinding The upper surface of the groove 14 is fixedly connected.

[0031]In this embodiment, when the permanent magnet block 11 is subjected to the repulsive force of the ring magnet 12 and moves to a lower position close to the electromagnetic spring 24, as the stirring blade 10 drives the permanent magnet block 11 to rotate, the magnetic flux in the electromagnetic spring 24 changes, According to the principle of electromagnetic induction, when the magnetic flux in the closed loop changes, an induced current is generated in the closed loop, and then an induced current is generated in the electromagnetic spring 24, and an induce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com