Foreign odor eliminating method for drum washing machine

A drum washing machine and odor elimination technology, which is applied to the control device of the washing machine, other washing machines, washing devices, etc., can solve the problems such as odor, and achieve the effect of preventing and solving the problem of odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

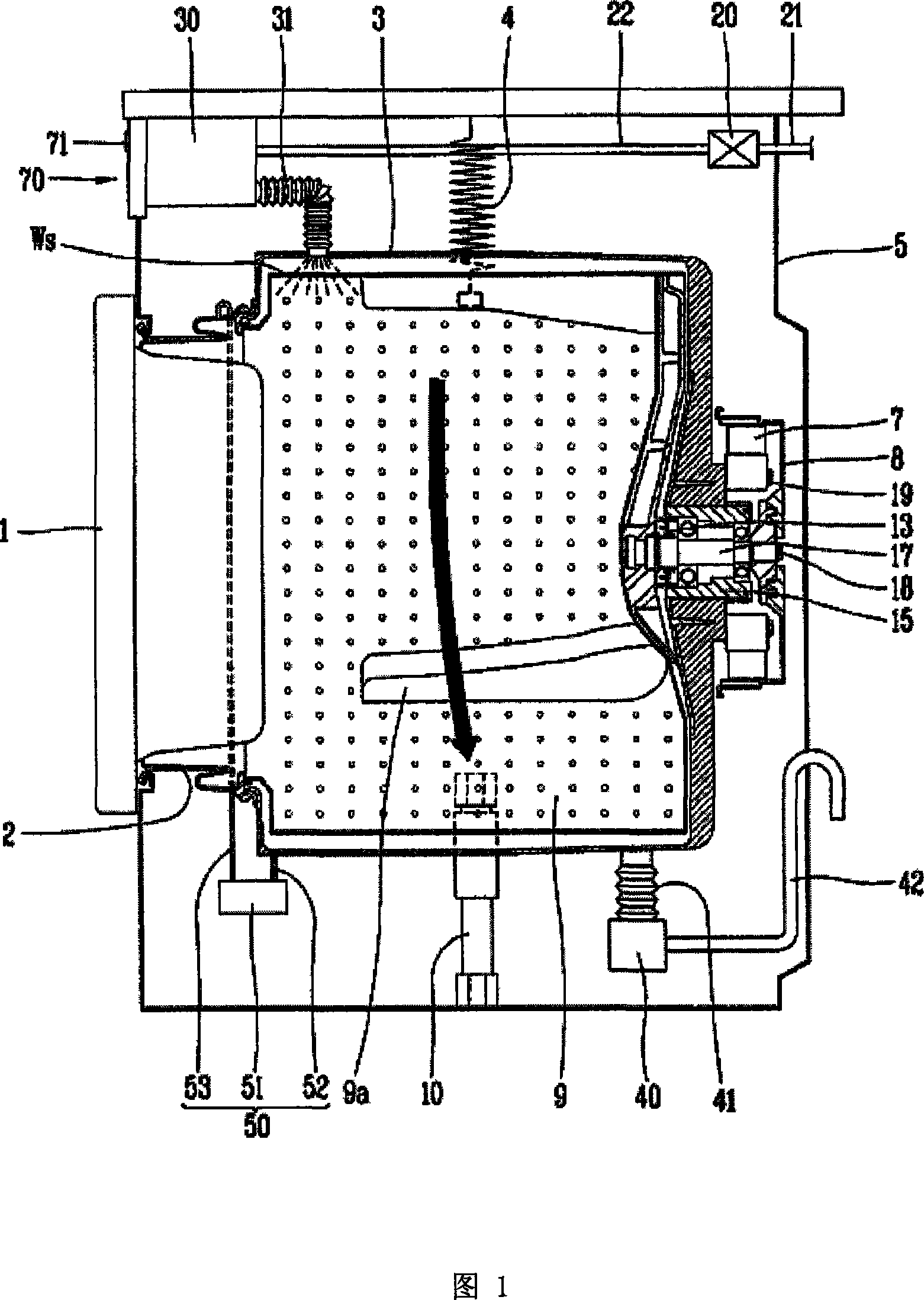

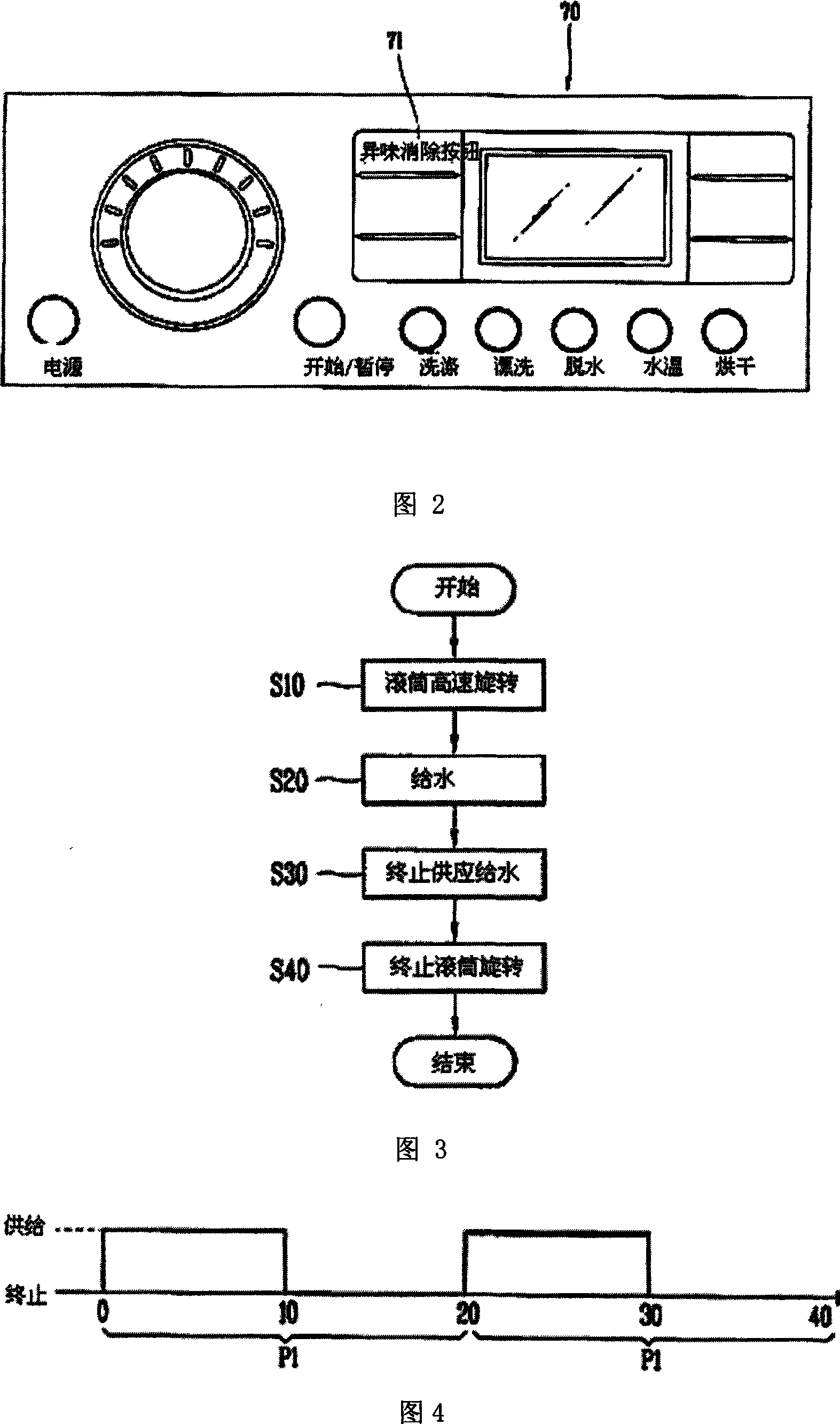

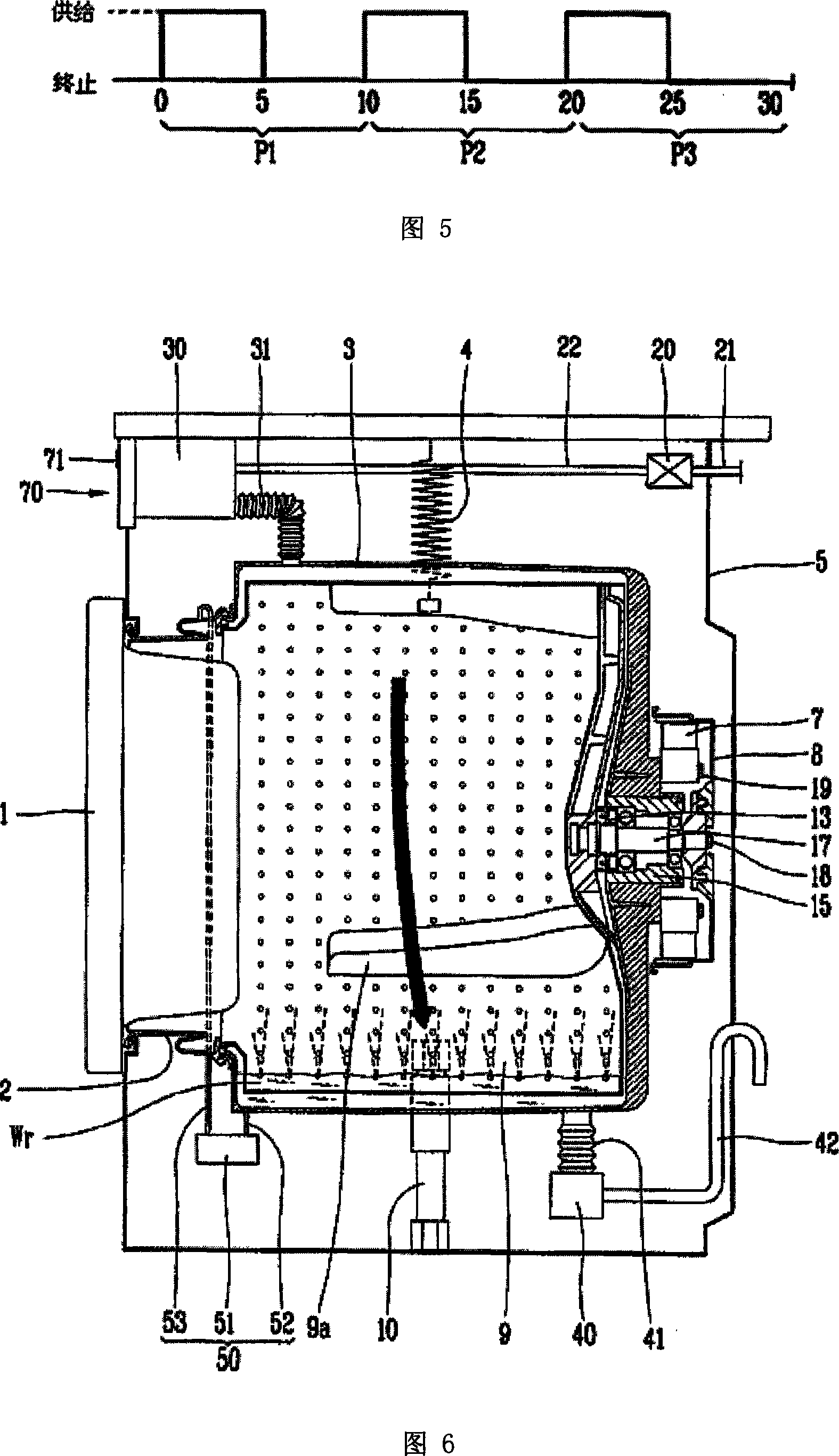

[0022] The odor elimination method of the drum washing machine of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. Fig. 1 is a schematic diagram of a front-loading washing machine driven by the method for eliminating odors in the first embodiment. Fig. 2 is a drawing showing the control panel equipped with the odor eliminating button in Fig. 1, and Fig. 3 is a diagram showing the first embodiment of Fig. 1 Block diagram of the case's odor elimination method.

[0023] With reference to Fig. 1, the drum washing machine driven by the method for eliminating peculiar smell according to the first embodiment of the invention includes the following parts: a casing 5 forming an appearance, an outer tub 3 installed inside the casing 5 and storing washing water, and an outer tub installed in the outer tub , and a rotatable drum 9 containing laundry, a washing motor 7 and 8 for rotating the drum 9, a rotating shaft 17 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com