Curved sliding vane type rotary compressor

A rotary compressor and sliding vane technology, used in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve problems such as increased leakage, difficulty in smoothness of sealing parts, and wear at chamfers. Achieve the effect of small mechanical wear, small leakage and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

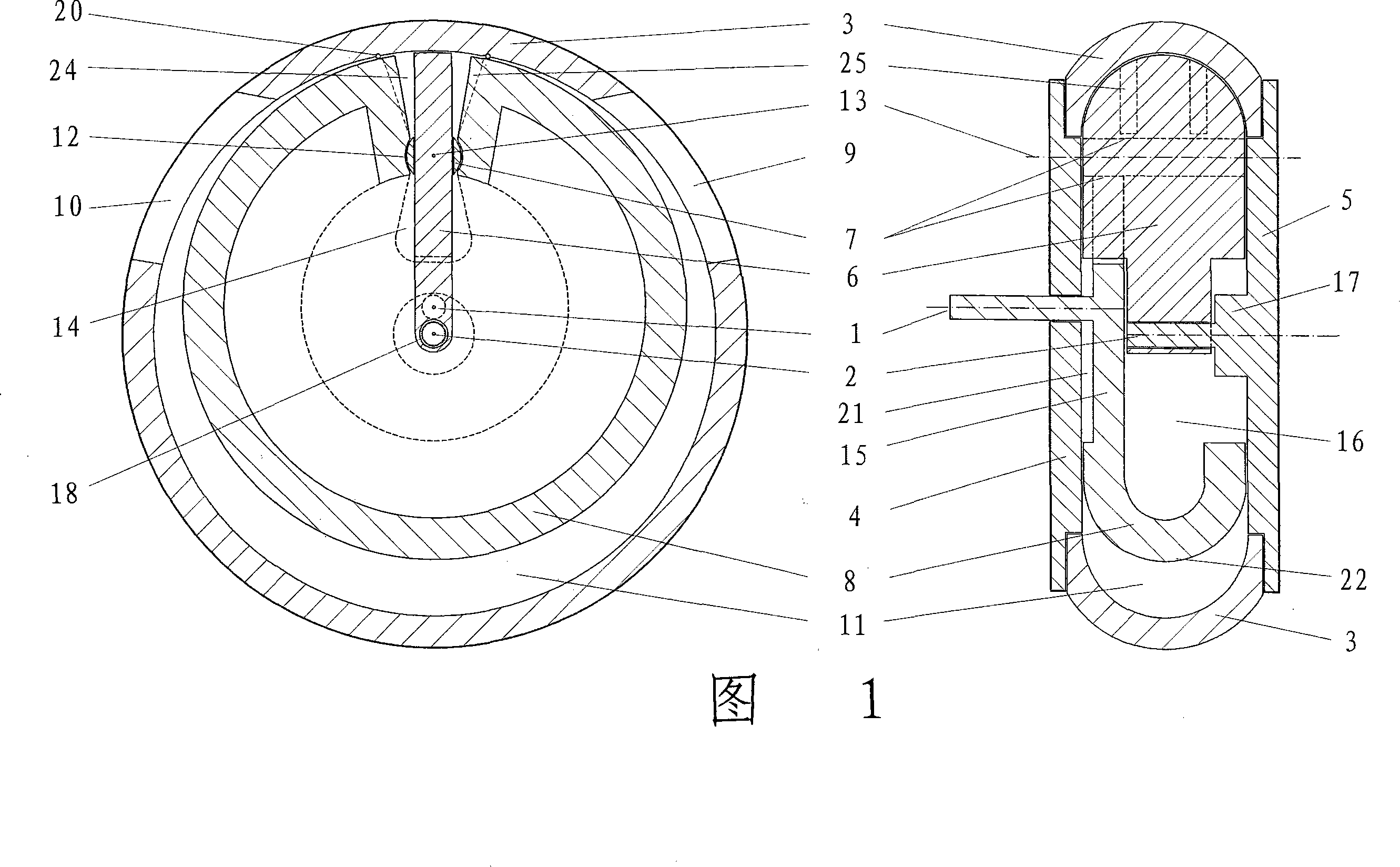

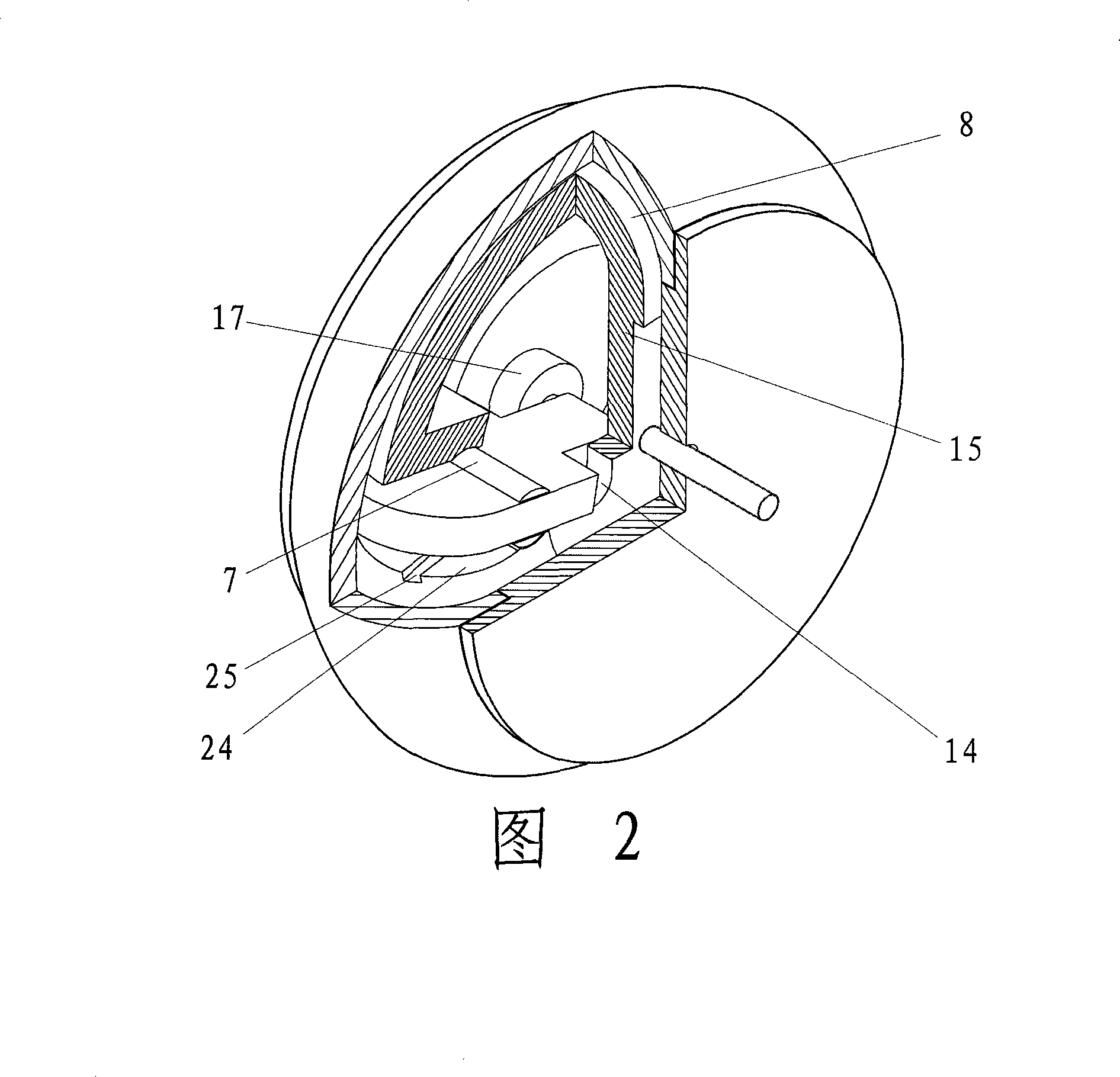

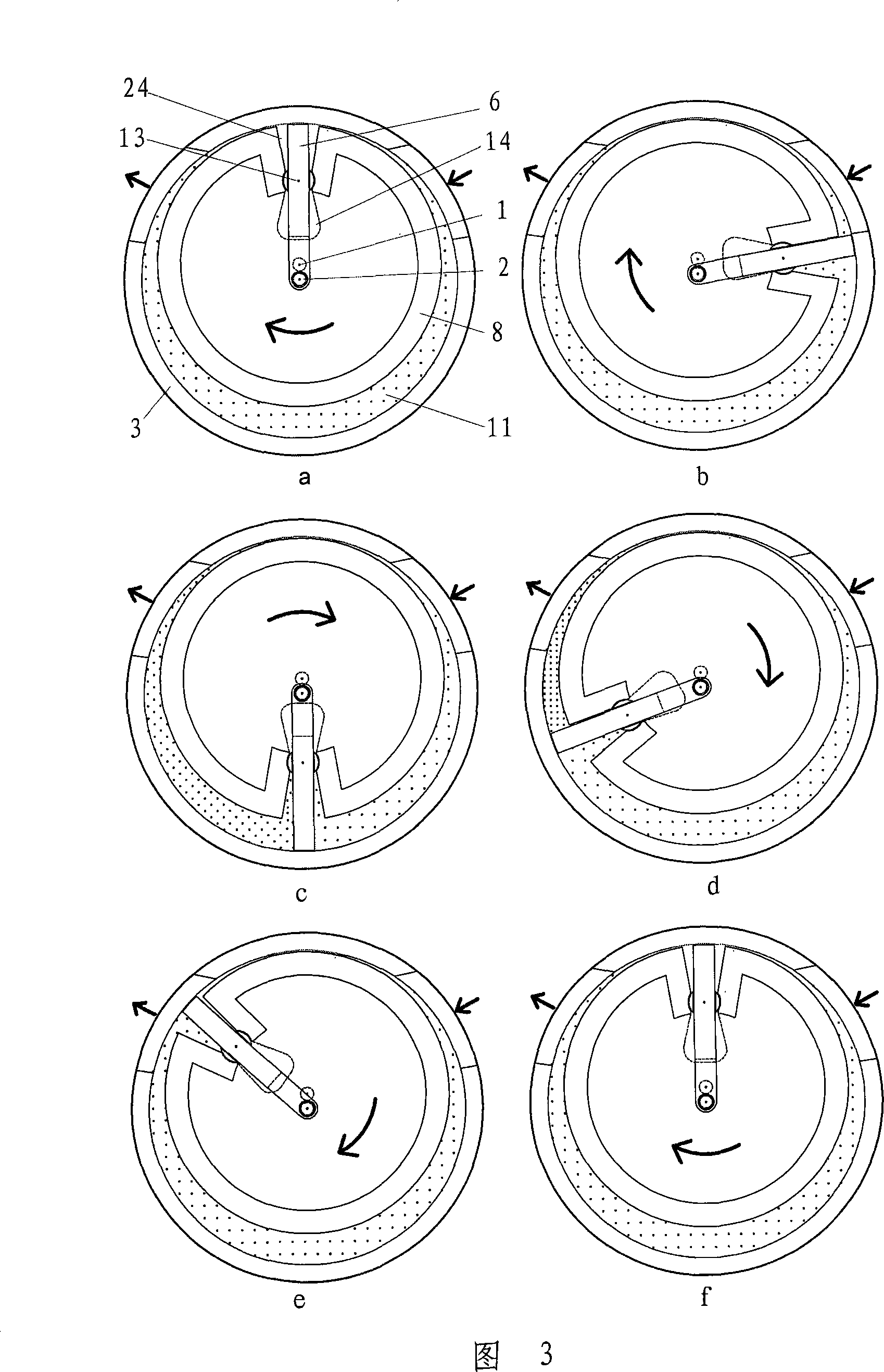

[0034] 1, 2, 5, the compressor of the present invention includes a cylinder block 3, a first end cover 4 and a second end cover 5 to form a compressor shell, in this embodiment, the first end cover is the front end cover 4, and the second end cover is Two end caps are rear end caps 5. The cylinder block 3 is in the shape of a ring, and its radial inner end surface is an inward annular curved surface, which is connected tangentially to the axial inner wall surfaces of the disc-shaped front end cover 4 and rear end cover 5 at its proximal part It encloses the inner chamber of the compressor, and the tangent point is 28 (see Fig. 4b). In this embodiment, the curved surface is a curved surface in the shape of an outer torus of a circular ring. It can be understood that the curved surface can also be a curved surface of other shapes, such as an ellipsoid, a paraboloid of revolution, and the like. There is an air inlet 9 and an exhaust port 10 on the cylinder block 3, a cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com