Method for improving low-speed performance of multi-cylinder engine

A multi-cylinder engine and engine technology, applied in engine components, engine control, machine/engine and other directions, can solve the problems of inability to open the engine valve, difficult engine cold start, high fuel consumption, etc., to eliminate cylinder pressure, reduce Emission and fuel consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

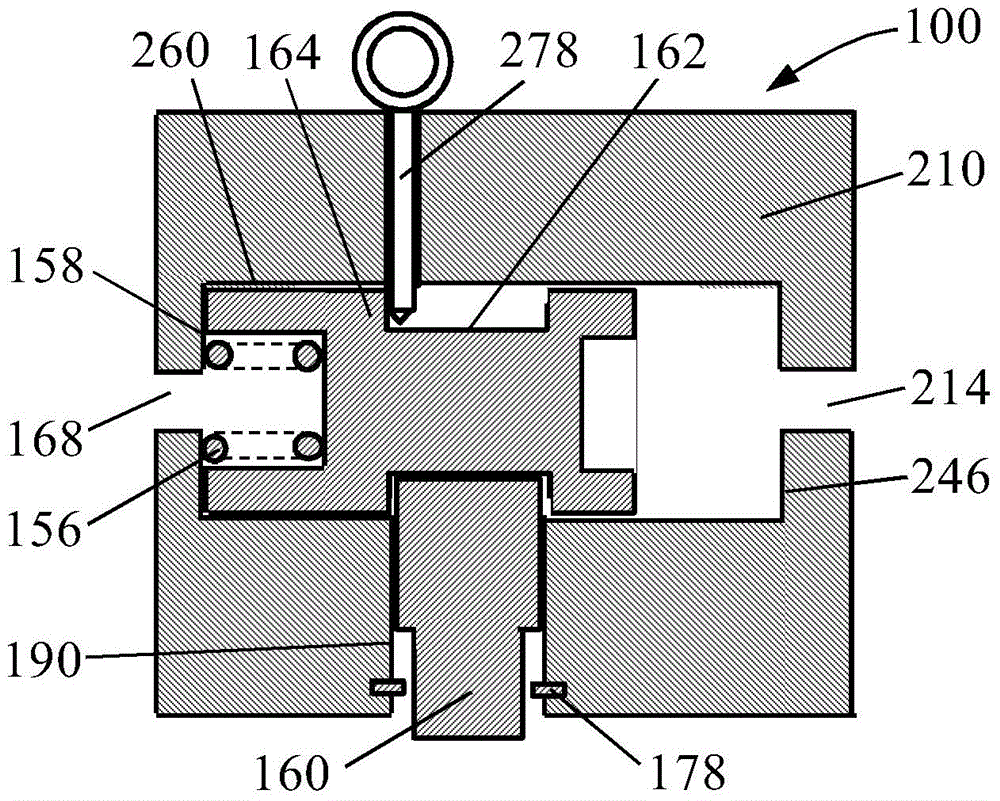

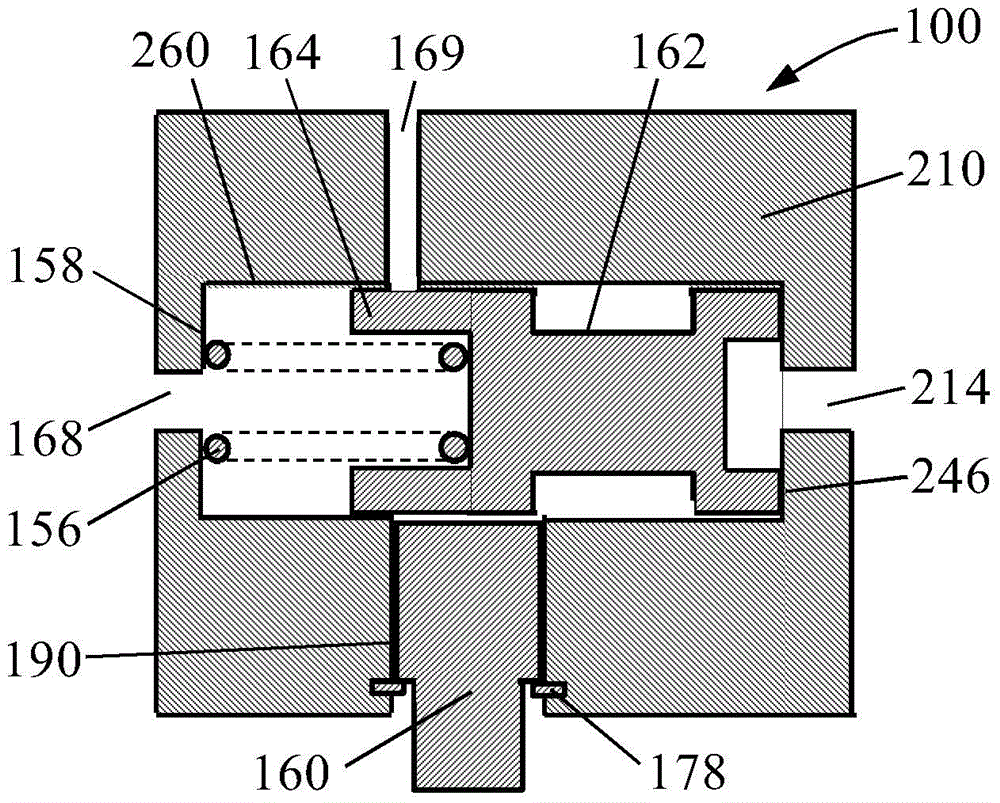

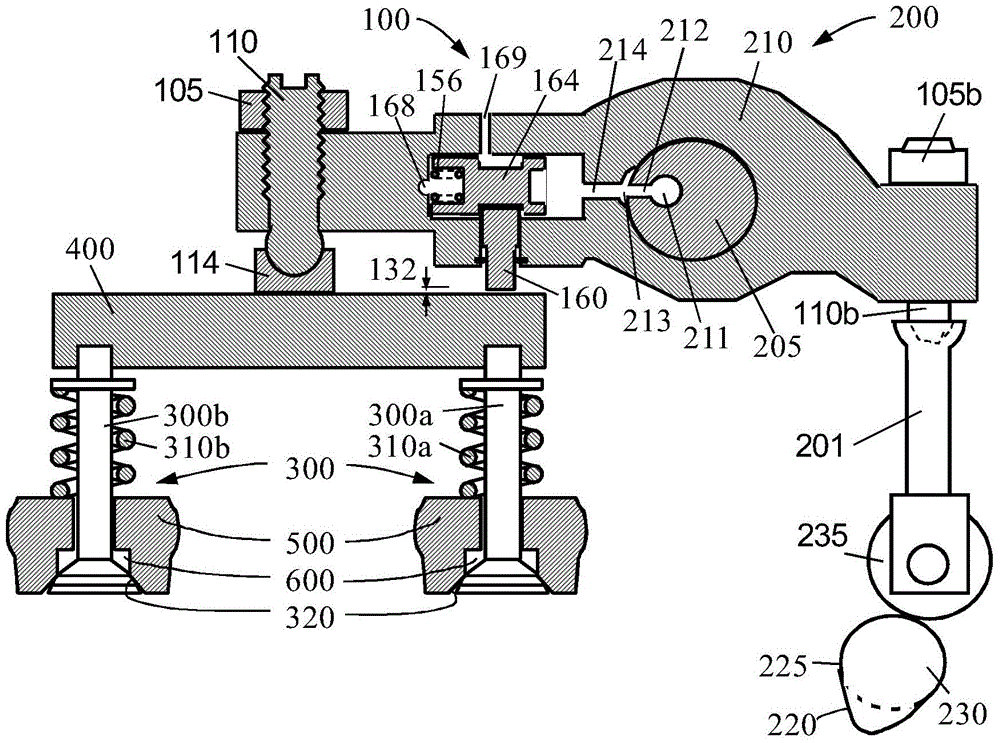

[0031] figure 1 , figure 2 , image 3 and Figure 4 Used to describe Example 1.

[0032] figure 1 and figure 2 It is described that the first embodiment of the present invention is in a non-operating state and an operating state respectively, wherein the fixed chain mechanism 100 includes a box body 210, a driving mechanism and a carrying mechanism. The casing 210 contains a driving piston hole 260 and a working piston hole 190 , and fluid passages 214 and 168 , which are perpendicular to each other and pass through each other. The drive mechanism includes a drive piston 164 and a drive spring 156 . The driving piston 164 is arranged in the driving piston hole 260 in the box body 210, the left and right ends of the driving piston hole 260 have stop surfaces 158 and 246 respectively, and the driving spring 156 is arranged at one end of the driving piston 164 (the left end in the figure), The other end of the driving piston 164 (the right end in the figure) is close to ...

Embodiment 2

[0038] Figure 5 and Figure 6 Used to describe Example 2.

Embodiment 2

[0039] Embodiment 2 is a continuous motion fixed chain mechanism 100 with a valve gap adjustment function, including a box body 210, a piston linkage mechanism and a valve gap adjustment mechanism. The casing 210 contains a driving piston hole 260 and a working piston hole 190 , fluid channels 214 and 168 , and a discharge channel 169 which are perpendicular to each other. The piston linkage includes an upper link 184 and a lower link 186 , a drive piston 164 and a working piston 160 . The drive piston 164 is seated in the drive piston bore 260 and the working piston 160 is seated in the working piston bore 190 . The driving piston 164 has a guide groove 137 . One end (the left end among the figures) of the driving piston 164 has a horizontal hole 183 that communicates with the guide groove 137, and a rolling ball 162 (also a piston) is arranged in the horizontal hole 183. The other end (the right end in the figure) of the driving piston 164 is provided with a spring 156 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com