Rotary piston type internal-combustion engine

A technology for internal combustion engines and rotary pistons, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as unsatisfactory economic performance and dynamic performance, and improve economic performance and dynamic performance, economic performance and dynamic performance Good, the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

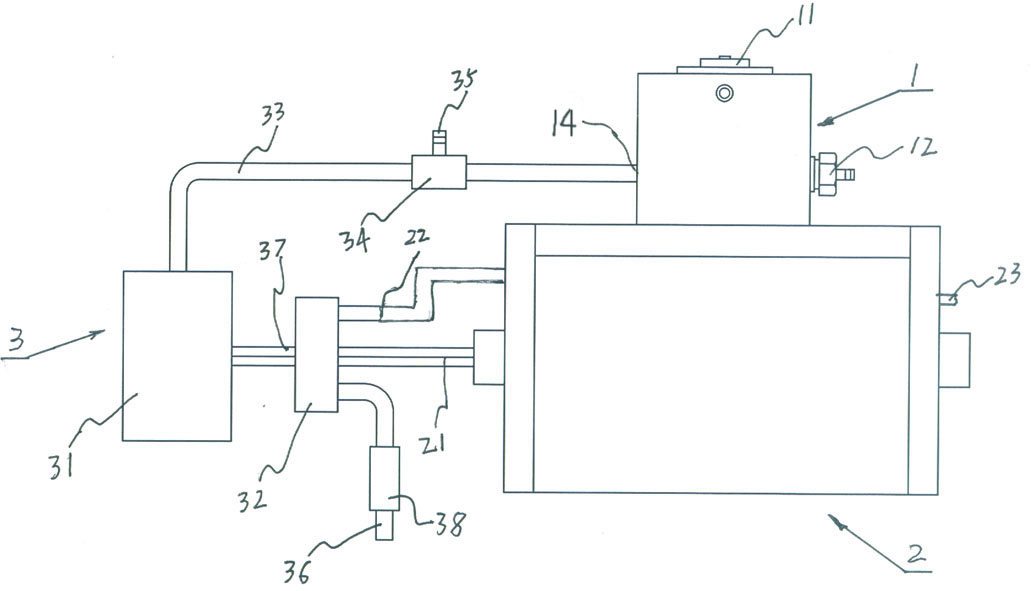

[0017] see figure 1 , which shows the overall structure of the appearance of an embodiment of the rotary piston internal combustion engine proposed by the present invention. The internal combustion engine includes a cylinder block and a fuel supply system 3 , wherein the cylinder block includes a combustion chamber block 1 and a working chamber block 2 .

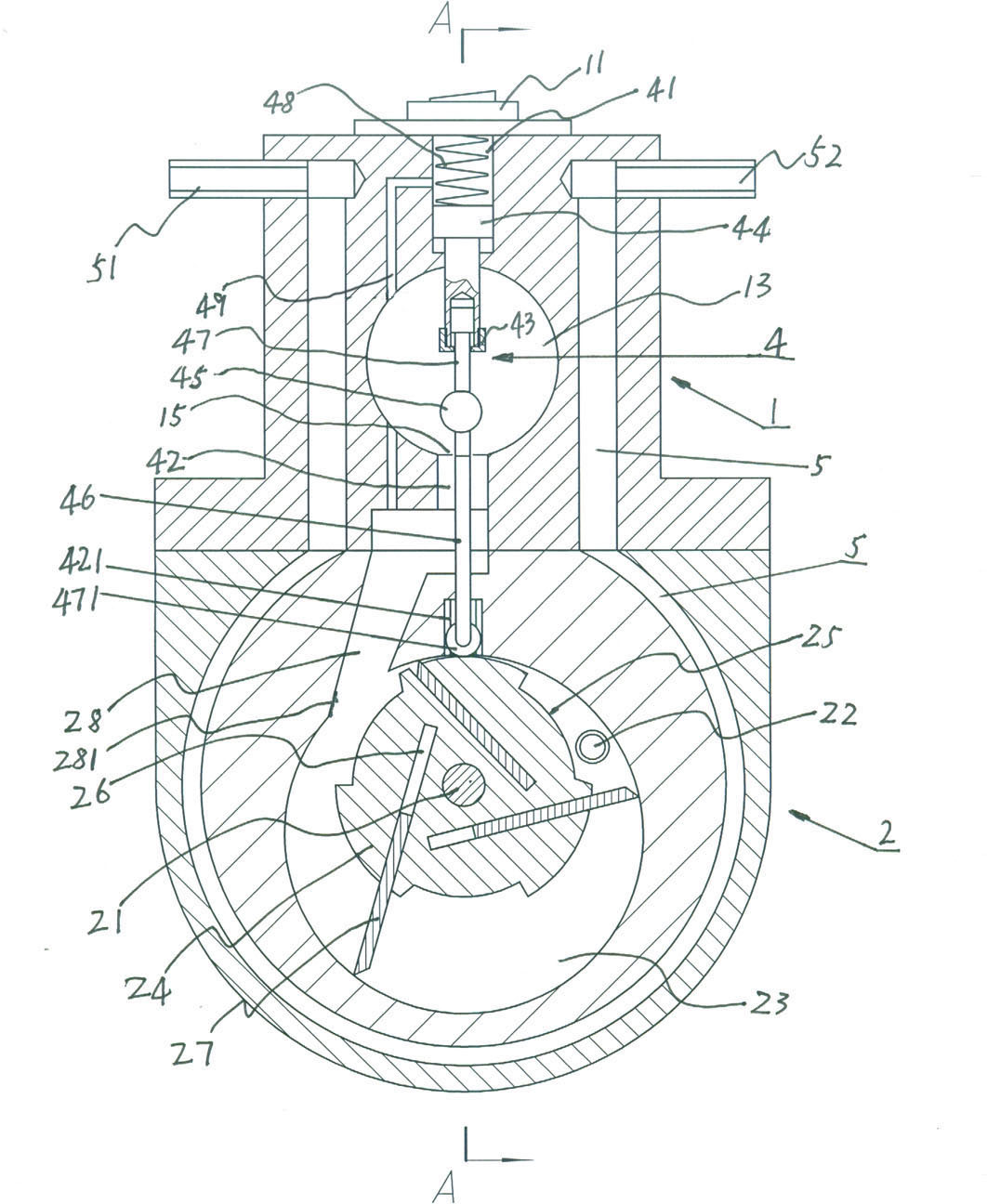

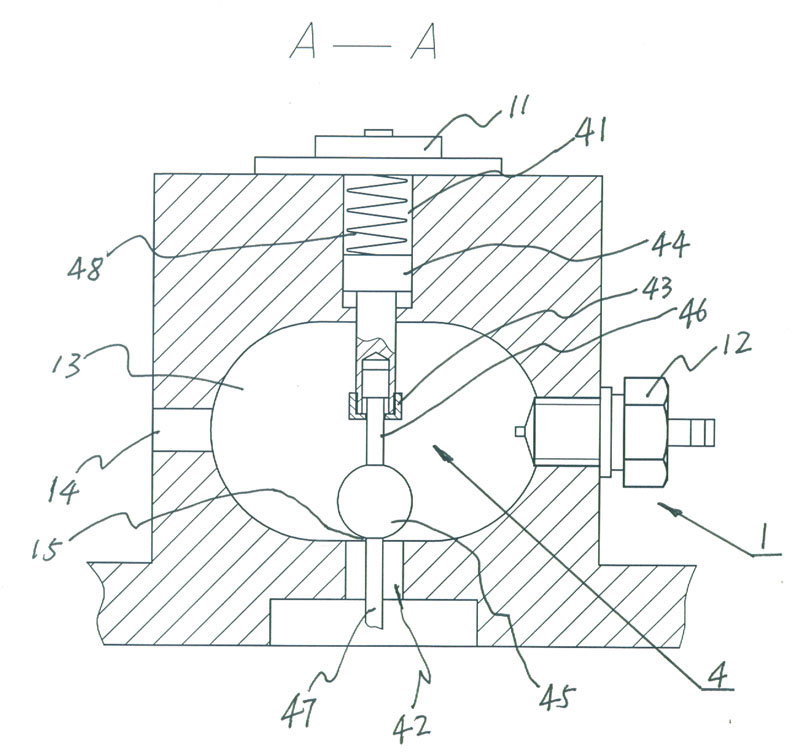

[0018] Timing switch 11 is installed on the top of combustion chamber cylinder block 1, and both sides are respectively provided with ignition device 12 and lead into combustion chamber 13 (referring to figure 2 or image 3 ) inside the fuel injection hole 14. Timing switch 11 among them is the part that controls ignition device 12 to open or close, because both belong to prior art, so do not provide specific structure in the figure; Working chamber cylinder block 2 has an output shaft 21 from appearance And the exhaust pipeline 22, and the oil injection hole 23, the exhaust pipeline 22 can discharge the waste gas with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com