LED spotlight

A technology of LED floodlights and light-emitting boards, which is applied in the direction of light sources, electric light sources, point light sources, etc., can solve the problems of large and uniform light emitting angles, increased costs, and application restrictions, and achieve improved light projection effects and increased angles , the effect of increasing the irradiation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

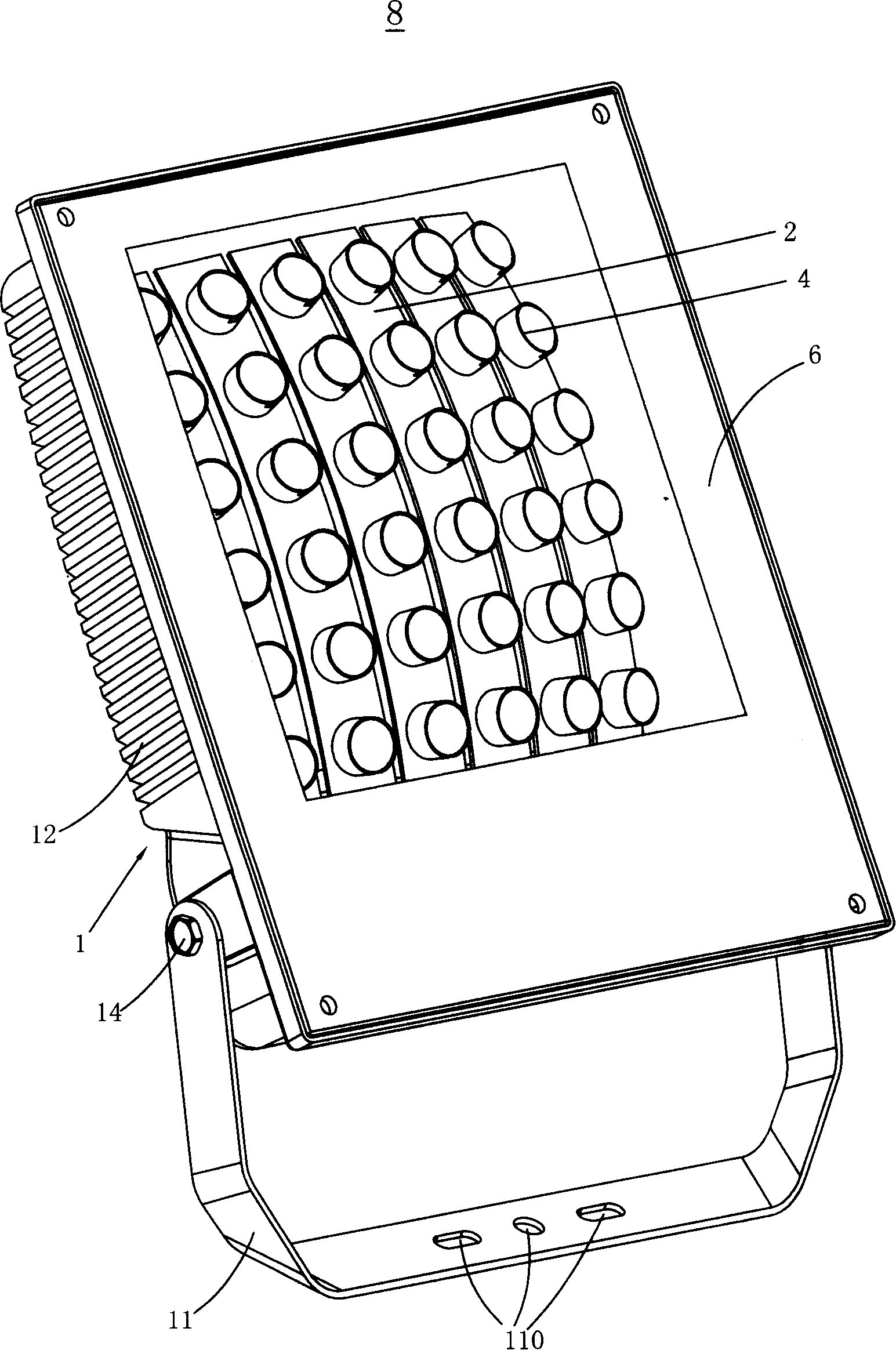

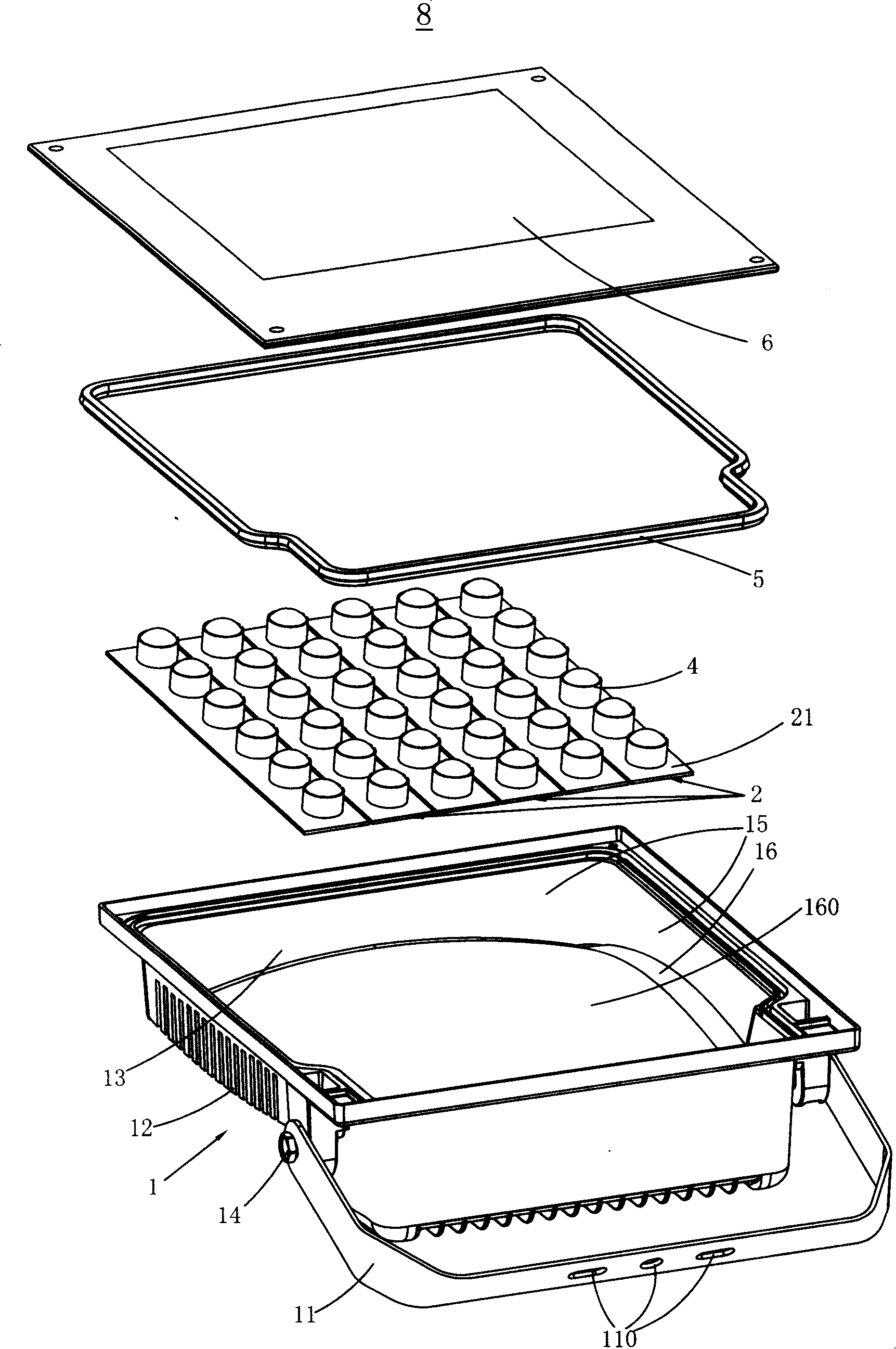

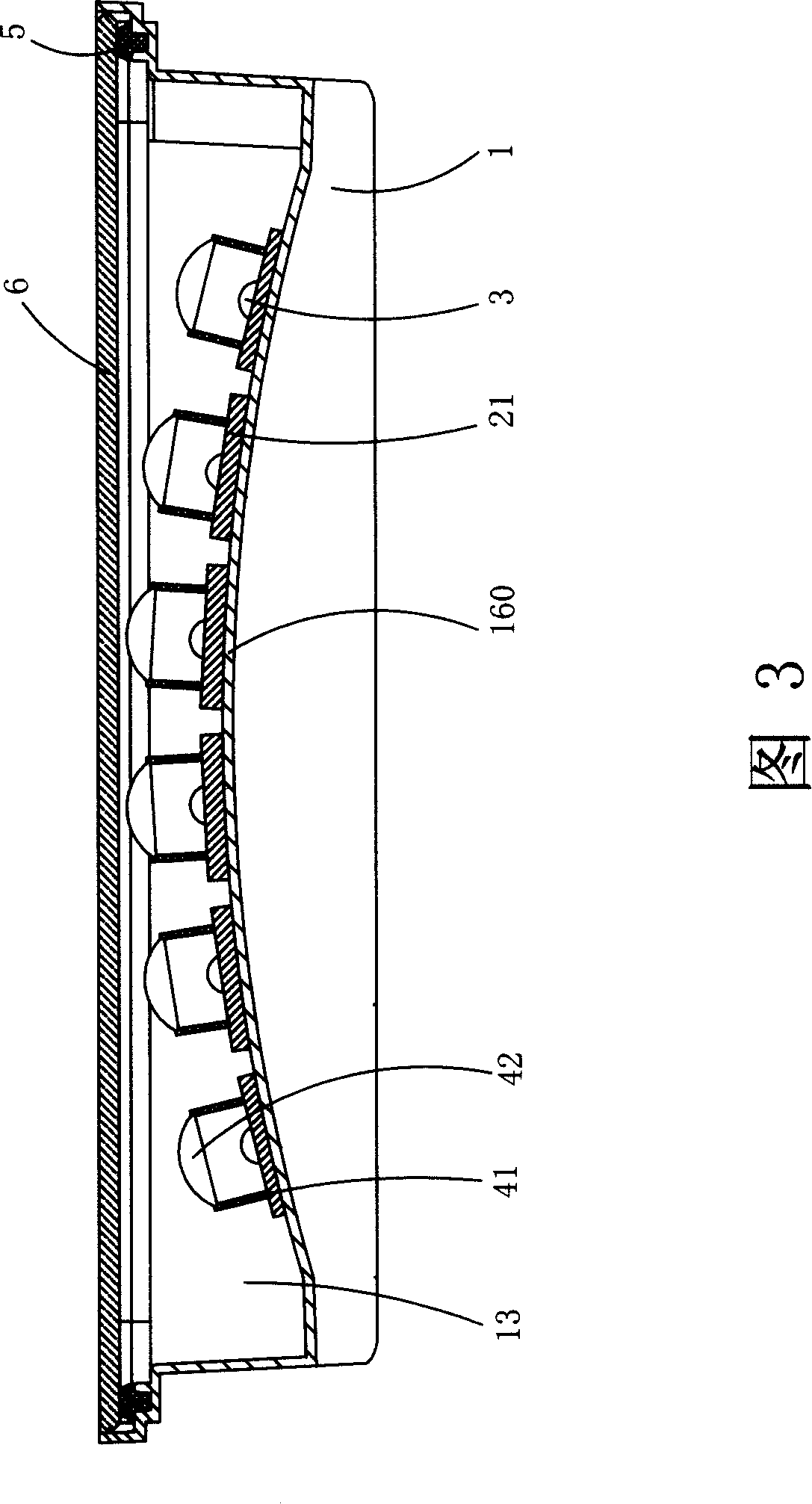

[0024] see figure 1 , figure 2 , Figure 3 and Figure 4 As shown, the floodlight 8 disclosed in this embodiment includes a housing 1, a circuit board 2, an LED 3, a lens unit 4, a sealing ring 5 and a light output plate 6, wherein the LED 3 is housed in the housing 1, The light-emitting plate 6 is fixed on the housing 1 and the LED 3 is enclosed in the housing 1. The LED 3 is arranged in a convex arc shape in the direction of the light-emitting plate 6 in the housing 1. The outer The central angle of the convex arc surface ranges from 10 degrees to 100 degrees, and the LED 3 is a high-power LED (in this embodiment, its power is greater than or equal to 1 watt).

[0025] The housing 1 is made of a material with good thermal conductivity (for example, aluminum), and the housing 1 includes a bottom wall 16, four side walls 15 and a receiving space surrounded by the bottom wall 16 and the side walls 15. 13. The center of the bottom wall 16 protrudes outward to form an arc-sh...

Embodiment 2

[0030] see Figure 6 As shown in FIG. 7 , the difference between the LED floodlight 8 ′ disclosed in this embodiment and the LED floodlight 8 disclosed in Embodiment 1 is that the arc-shaped base 160 ′ supporting the circuit board 2 ′ is not formed by the casing 1 'formed in one piece, but an additional arc-shaped base 160' for supporting the circuit board 2' is installed on the bottom wall 16' of the housing 1'. The bottom wall 16' of the housing 1' is a plane, and the arc-shaped base 160' is made of a material with good thermal conductivity, which is fixed on the bottom wall 16' by screws or other known methods. The circuit board 2' is mounted on the surface of the arc-shaped base 160' adjacent to the housing bottom wall 16', so that the LEDs 3' on the circuit board 2' are distributed in an arc along the surface of the arc-shaped base 160'. The light emitting board 6' is mounted on the housing 1' by means of screw connection, etc., and the circuit board 2', LED 3' and lens ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com