Two freedom mobile parallel connection decoupling mechanism

A degree of freedom, parallel technology, applied in the direction of manipulators, program-controlled manipulators, joints, etc., can solve the problems of low stiffness, difficult calibration, complex control of parallel mechanisms, etc., to achieve good force characteristics, high motion accuracy, and high transmission efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation and specific operation procedures, but the scope of protection of the present invention is not limited to the following Mentioned examples.

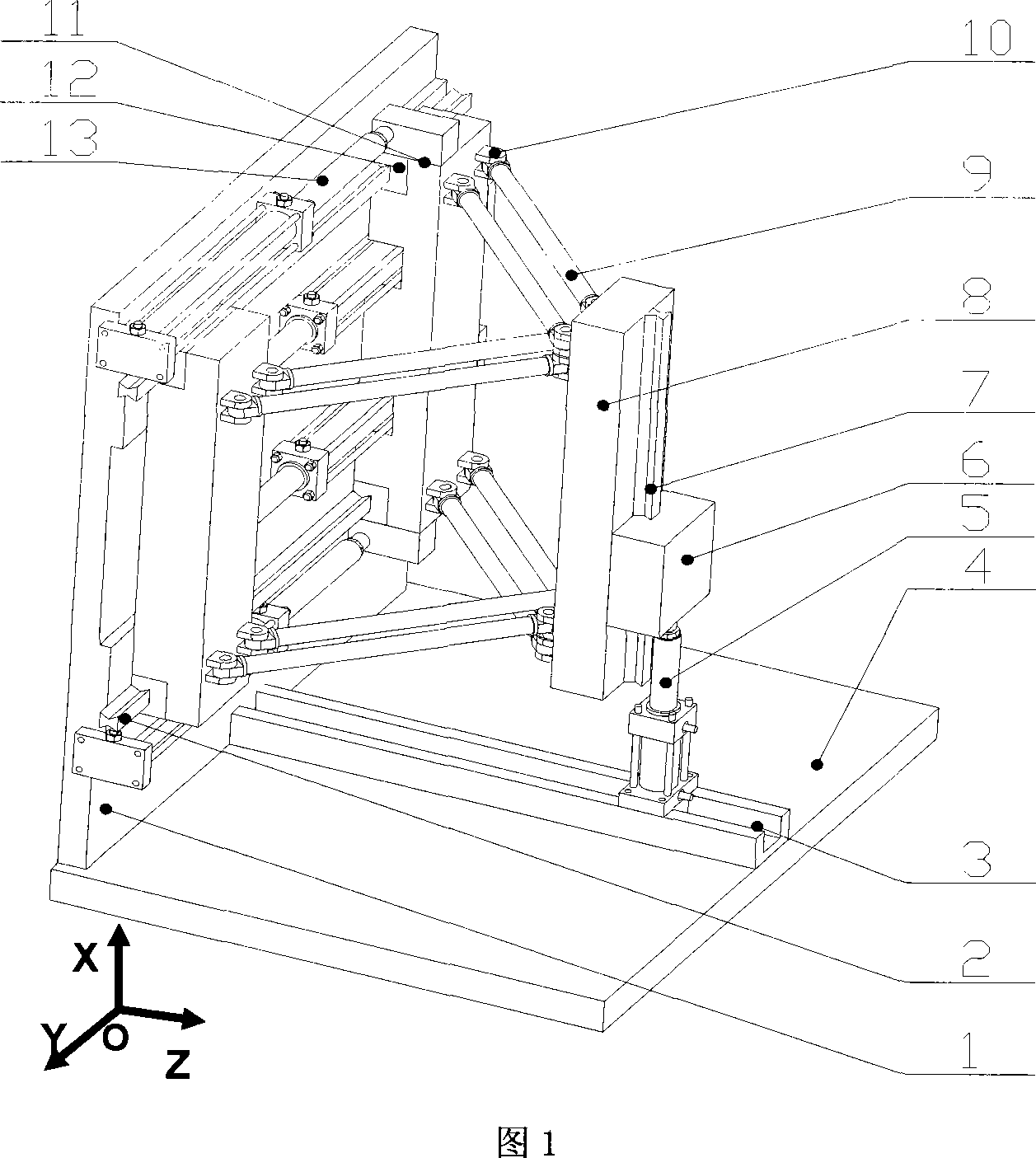

[0015] As shown in Figure 1, this embodiment includes the following components: 1-XOY basic platform, 2-Y guide rail, 3-Z guide rail, 4-YOZ basic platform, 5-X driving device, 6 moving platform, 7- X-direction guide rail, 8-upper support, 9-support rod, 10-rotation pair, 11-lower sliding support, 12-Y slide, 13-Y drive. Two Y-direction guide rails 2 are fixed on the XOY basic platform 1, the Z-direction guide rail 3 is fixed on the YOZ basic platform 4, the Y-direction slider 12 is fixed on the Y-direction guide rail 2, and the two lower sliding supports 11 are respectively fixed to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com