The pulsator that can rise and fall with the water level for washing

A pulsator and water level technology, applied in washing devices, washing machines with containers, textiles and papermaking, etc., can solve the problems of hinge deformation, limited lifting distance of the ridge head, easy entry of foreign objects, etc. Good laundry effect and the effect of increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The pulsator of the present invention is a modified pulsator, and the pulsator can be of any size, as long as the size of the pulsator can be optimally matched with the size of the bottom of the washing machine and assembled in the inner tub of the washing machine.

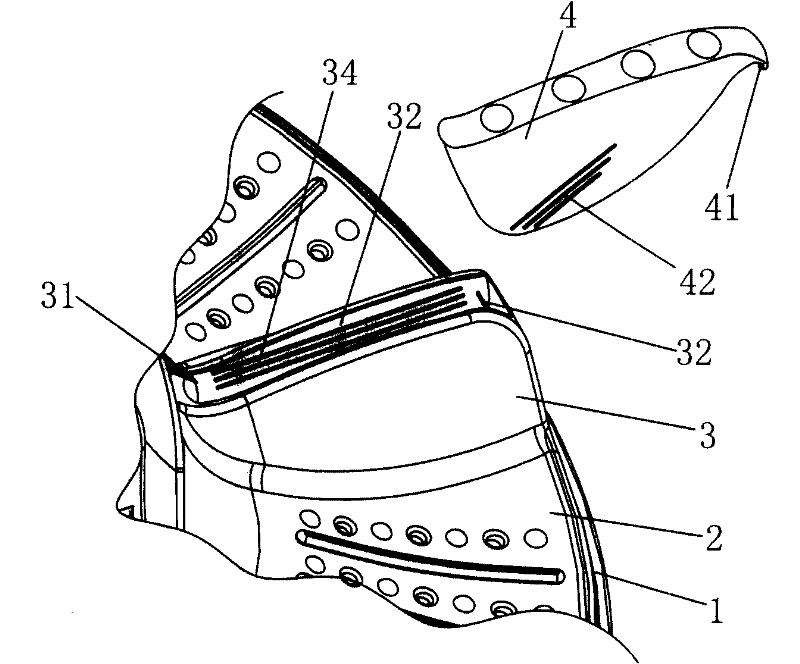

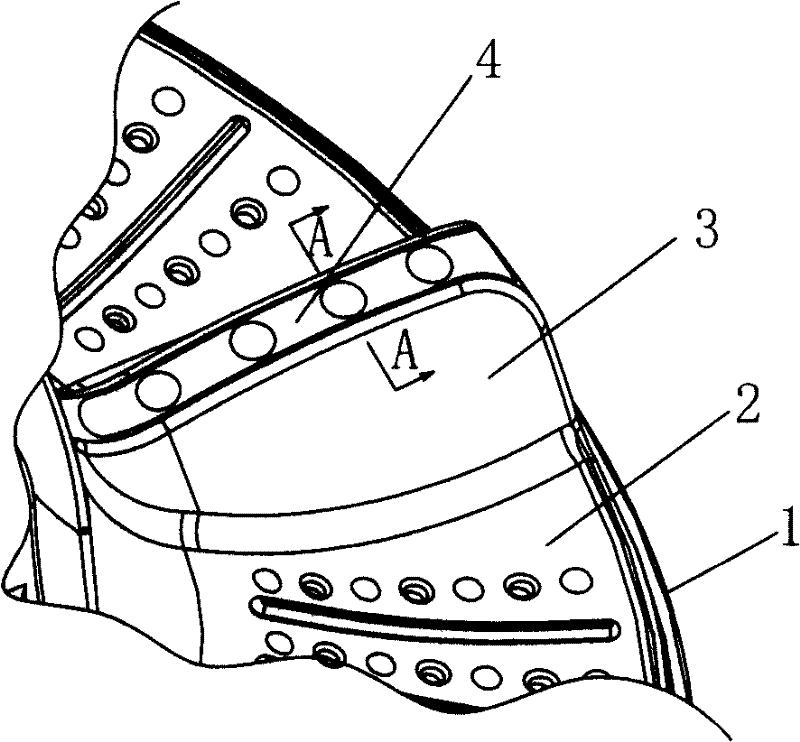

[0035] Such as Figure 2 to Figure 6As shown, the modified pulsator of the present invention includes a wave plate 1 and a plurality of ridge plates 2 arranged on the upper surface of the wave plate 1, and each ridge plate 2 includes a ridge plate base 3 arranged on the upper surface of the wave plate 1, The interior of the ridge base 3 is hollow and its upper surface is provided with an opening 31, forming a groove 32 with the hollow interior, and a ridge 4 is connected in the groove 32, and the end of the ridge 4 near the center of the wave plate 1 can be removed from the The opening 31 is raised upwards to adjust the height of the ridge base 3 .

[0036] Ridge board base body 3 interior hollow of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com