Method for separating pneumatic power transfer transmitting and receiving work terminals and device thereof

A pneumatic transmission and working end technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of unsightly, inconvenient operation, inconvenient to put in the transmission carrier and take out the transmission carrier, etc., and achieve the effect of simple operation and refreshing working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

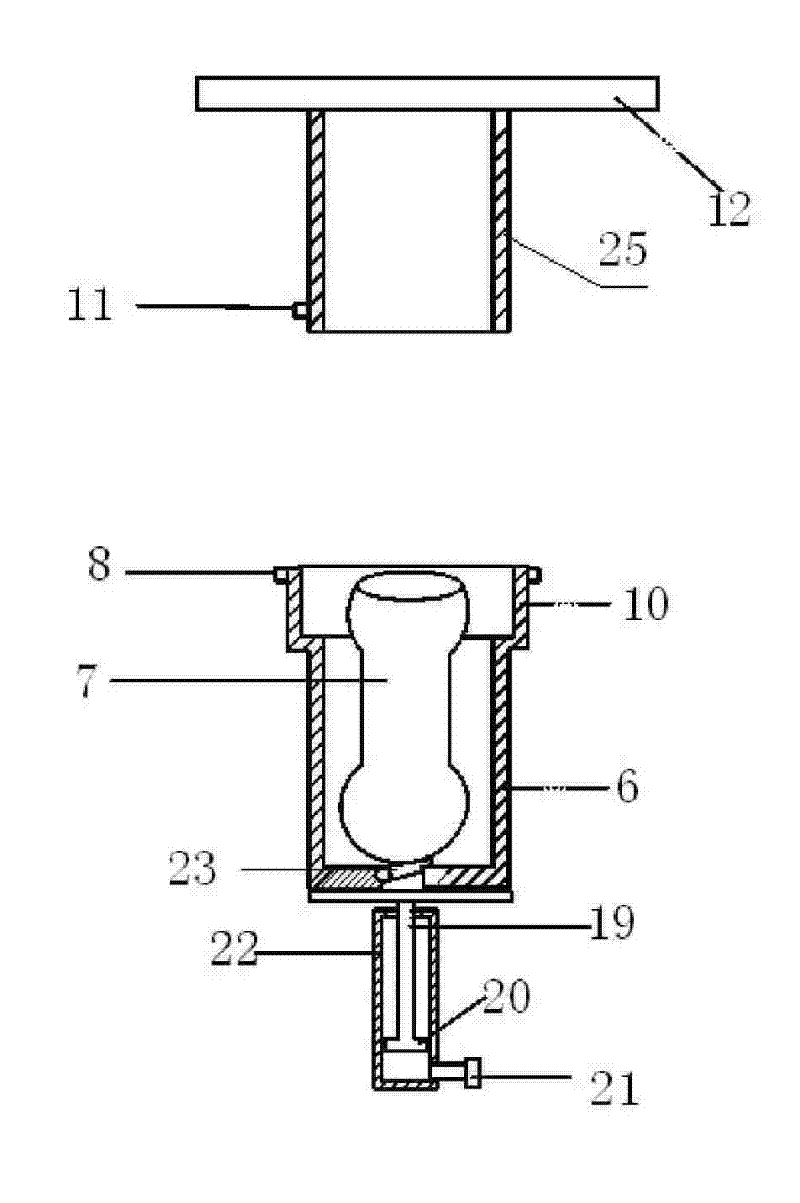

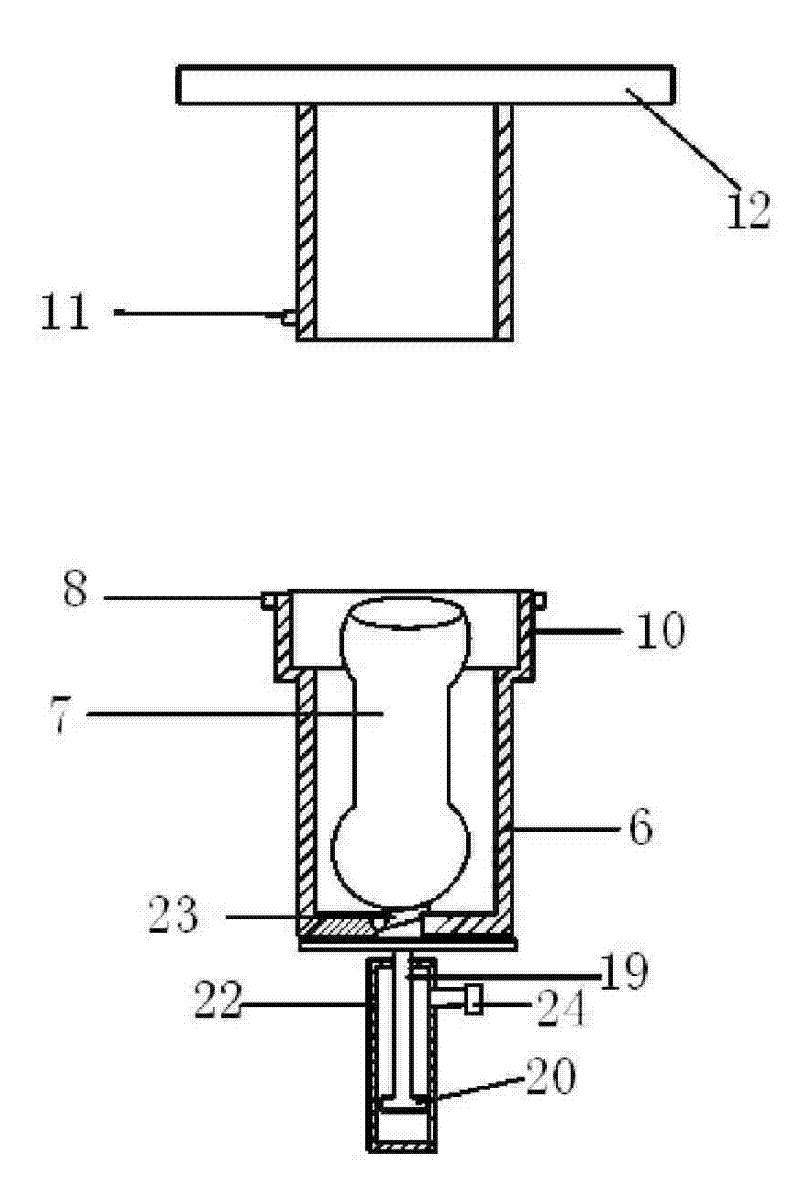

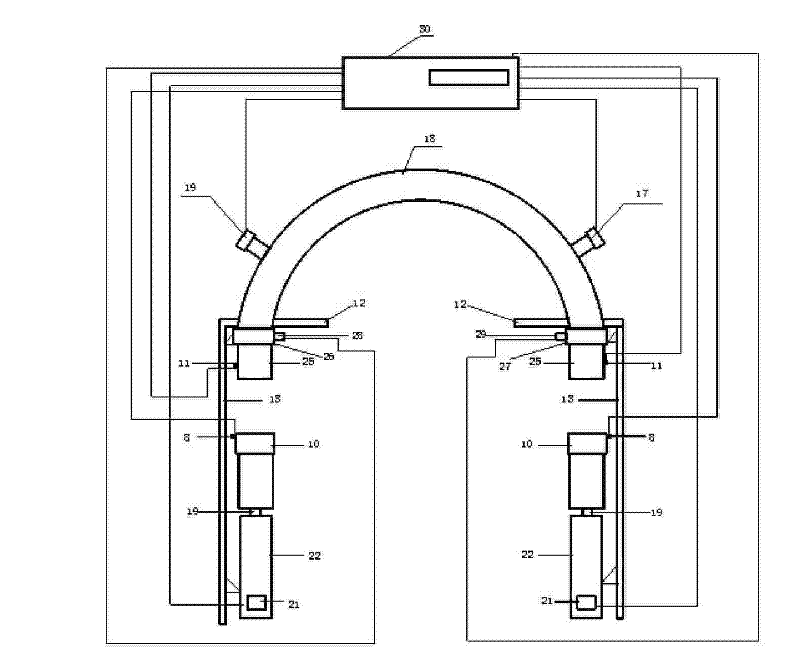

[0054] Such as figure 1 As shown, 23 is an air intake replenishing and exhaust damping mechanism, which is installed on the half part of the pipe section 6 with blocking measures. It is a door connected with the pipe body hinge, and the door can only be opened inwardly. There is a small hole in the place corresponding to the door, and the door can be sealed to replenish the air in time when the transmission carrier is sucked away, and prevent the discharge of air when the transmission carrier falls; 19 is the top bar mechanism, The upper side is fixedly connected to the lower end of the support to connect the piston 20, and the sending and receiving end pipes are installed on the support, and the piston can slide up and down in the cylinder body, and is used to move up and down by the pressure in the cylinder body 22 to drive the sending and receiving end pipes 6 moves up and down, 6 is a pipe section coaxial with the end of the transmission pipeline, and has a cut-off device ...

example 2

[0059] like Figure 4 , 5 As shown, 16 is the pipe section of the sending and receiving working end, which is fixed on the support with a side hinge shaft. After swinging, it is coaxial and has the same diameter as the transmission pipe 6. External force can be added to the working end pipe body or fixed with the working end pipe body. On the connected shaft, after adding force, the two bodies can be anastomosedly connected, and the others are the same as in Example 1.

example 3

[0061] like Image 6 , 7 , Shown in 8, 14 is the horizontal hinge shaft, 16 is the sending and receiving working end pipe section, and the hinge shaft is fixedly connected on the support; other is the same as example 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap