Low-noise dry type arc suppression coil and method for reducing noise of arc suppression coil

An arc suppression coil, low-noise technology, applied in transformer/inductor noise damping, transformer/inductor coil/winding/connection, transformer/inductor core, etc., can solve the problem of high noise of arc suppression coil, etc. Uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

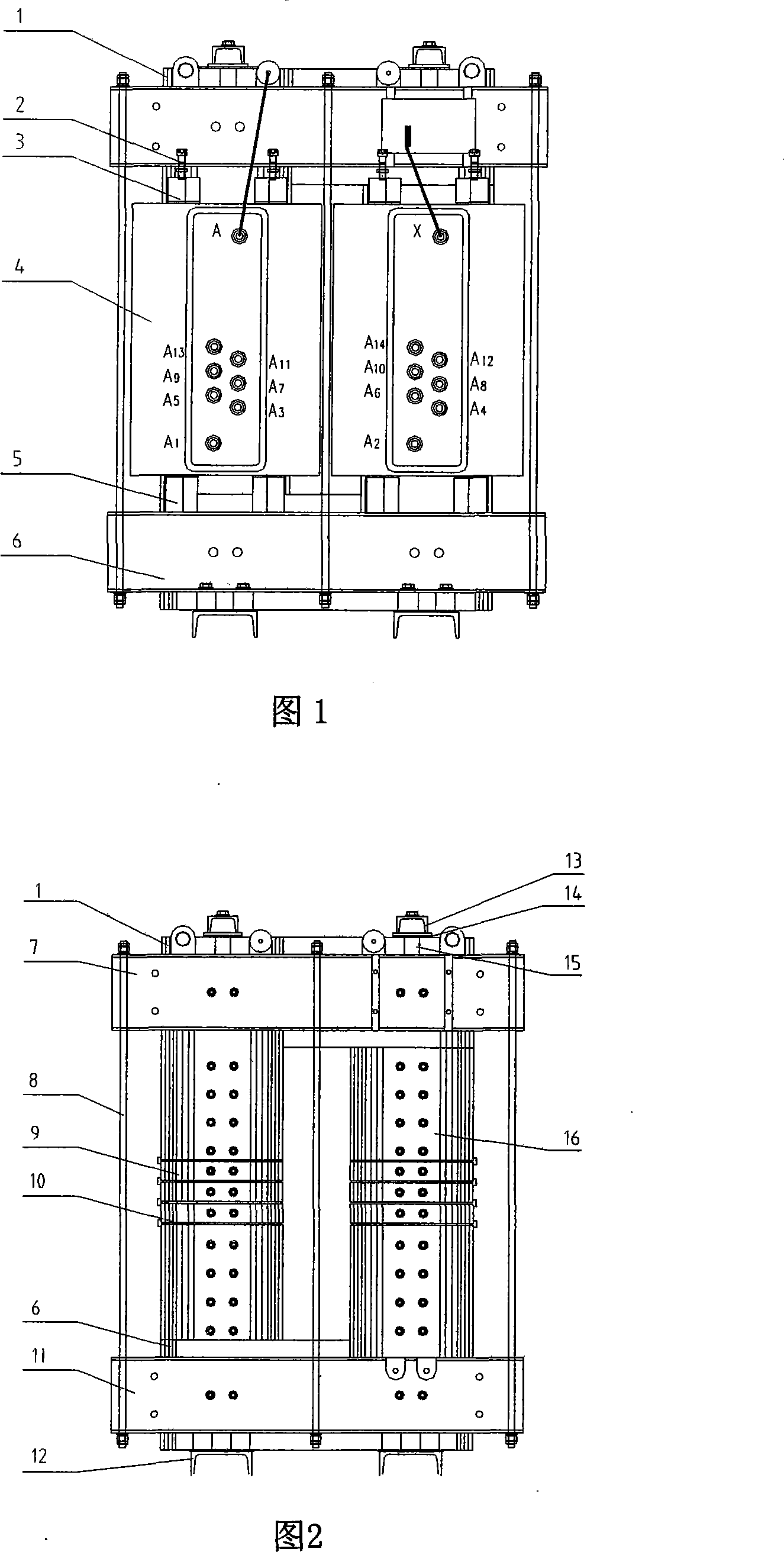

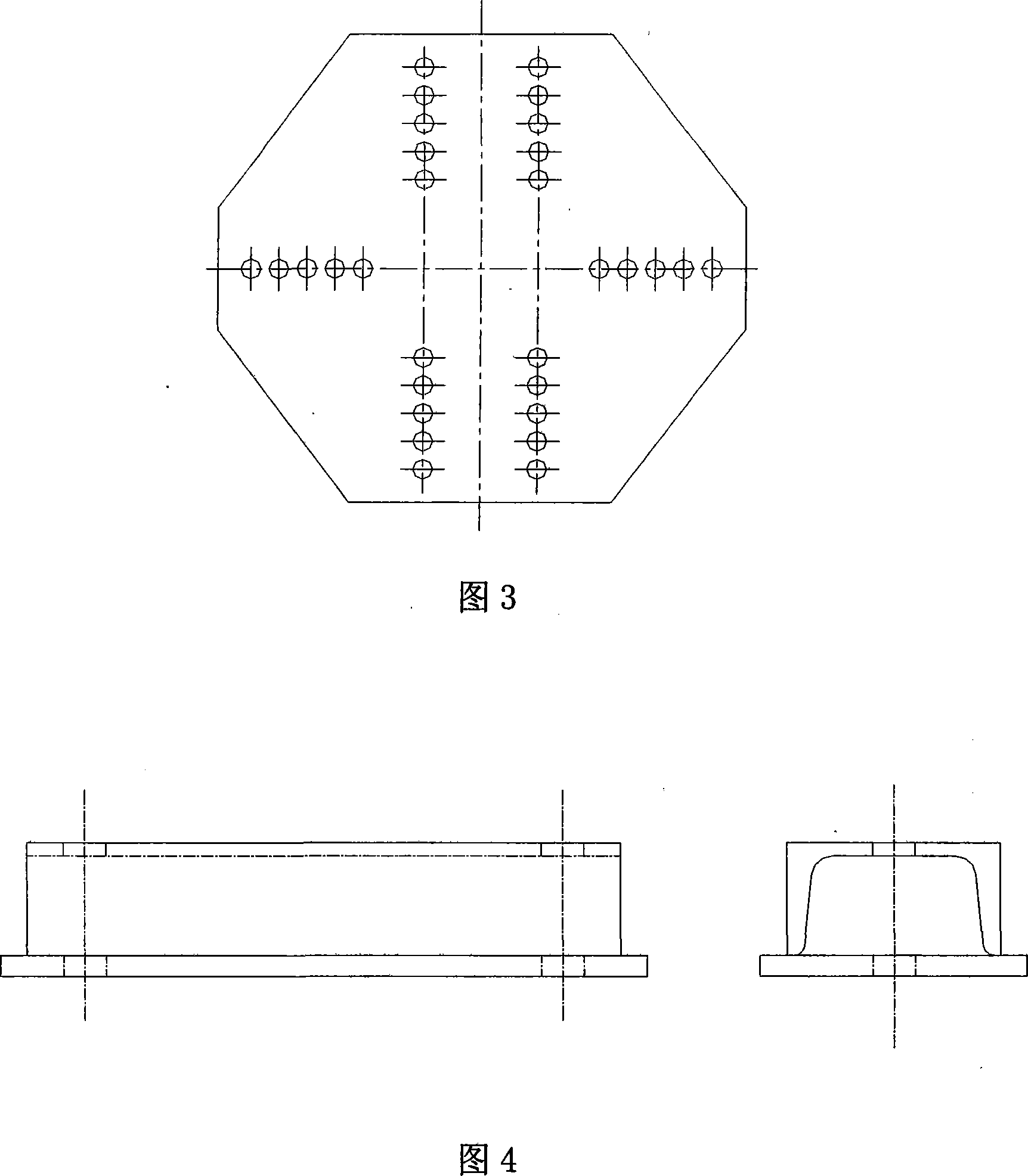

[0019] Example: A low-noise dry-type arc suppression coil (see Figure 1), consisting of an iron core with no less than one air gap, an air gap pad 10, a coil 4, an upper block 3, a lower block 5, Composed of pressing nail 2 and pulling screw 8, in which the iron core (see Figure 2) is divided into four parts: iron core column 16, iron core cake 9, upper iron core yoke 1 and lower iron core yoke 6, and the air gap pad 10 is set Between the iron core column 16 and the iron core cake 9 of the iron core, the coil 4 is sleeved outside the iron core, the upper block 3 is pressed against the coil 4 by the pressing nail 2, the coil 4 is pressed on the lower block 5, and the screw is pulled 8 are respectively connected with the upper iron core yoke 1 and the lower iron core yoke 6 of the iron core; it is characterized in that the upper iron core yoke 1, the iron core column 16, the air gap pad 10, the iron core cake 9 and the iron core The lower core yoke 6 is a whole that is cured togethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com