Jig lifting apparatus

A technology of lifting devices and fixtures, which is applied to assembly machines, manufacturing tools, workbenches, etc., and can solve problems such as difficult positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The best mode for carrying out the present invention will be described below using examples.

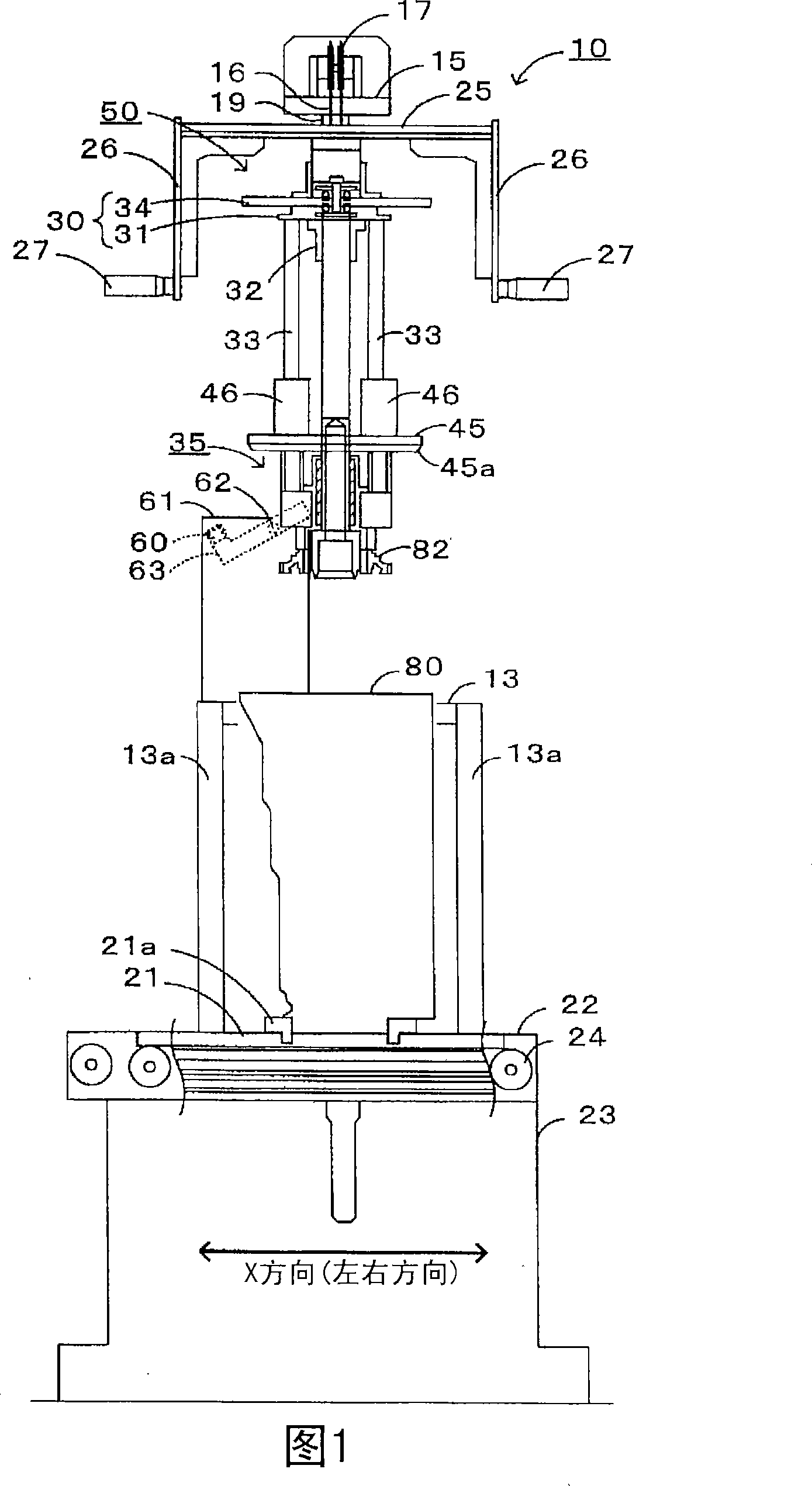

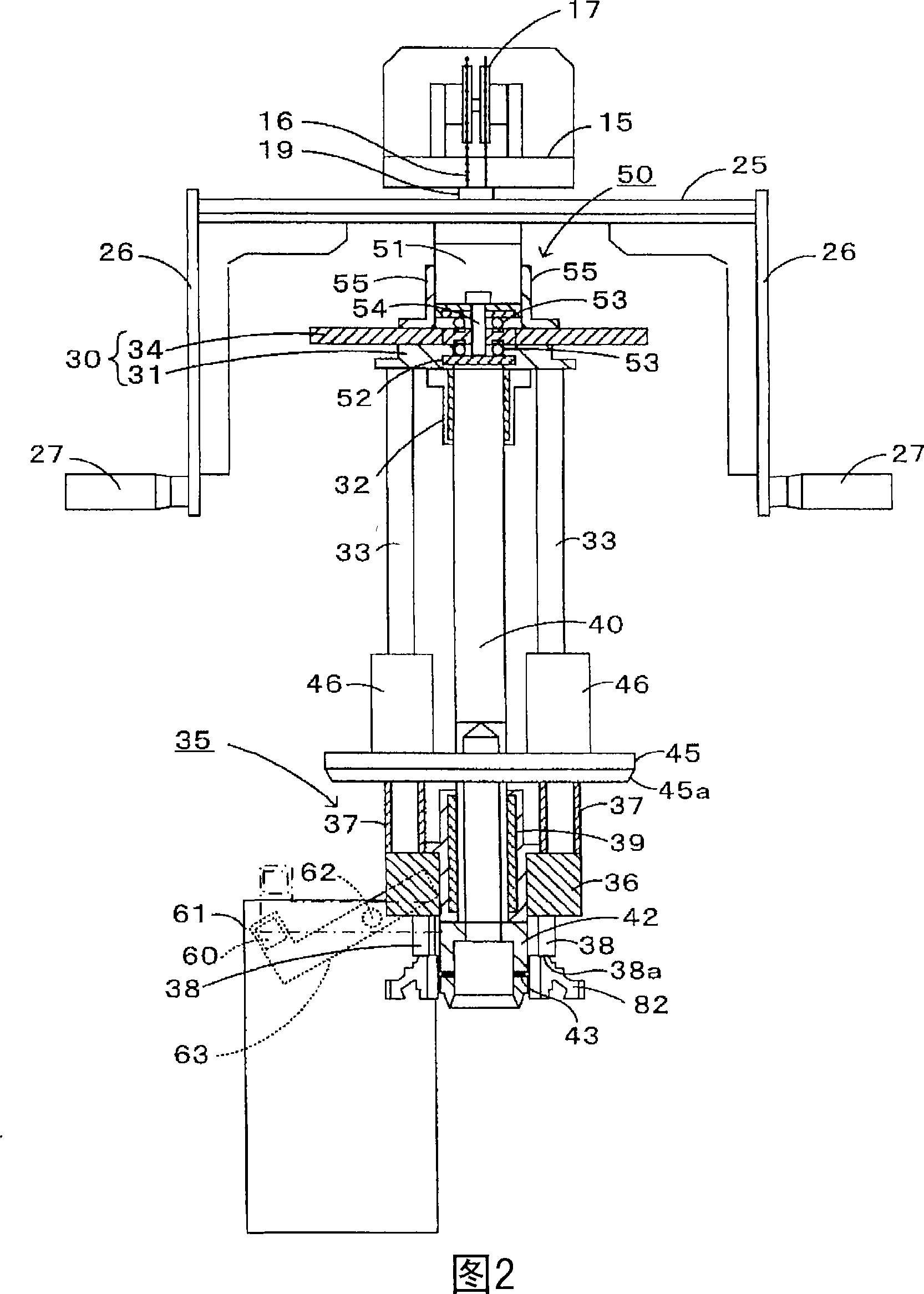

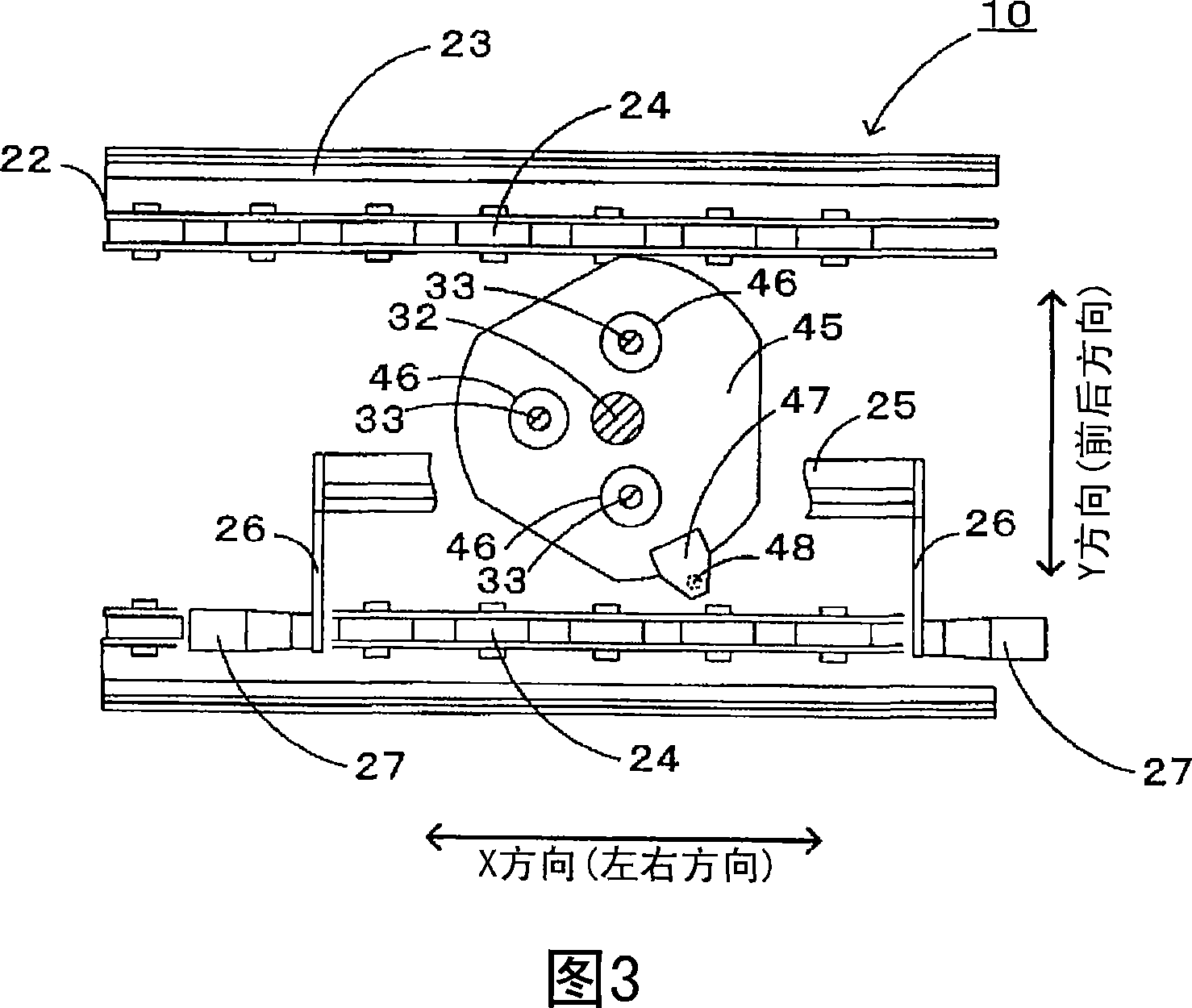

[0024] Fig. 1 is a front view of the clamp elevating device 10 of the present embodiment, Fig. 2 is an enlarged front view (partial sectional view) of the clamp 35, Fig. 3 is a top view (partial sectional view) of the clamp elevating device 10, Fig. 4 is a clamp elevating device 10 side view.

[0025] The jig lifting device 10 of the present embodiment has: a device stand 12; a pallet (pallet) 21 as a housing support platform, which is arranged below the device stand 12; a sliding seat 25 as a moving body, which is installed on the device stand 12, and can move up and down relative to the supporting plate 21; the horizontal plate 30, which is installed on the slide seat 25; the clamp 35, which is fixed on the lower ends of the three rods 33 extending downward from the horizontal plate 30; the base part 45 , which is installed on these rods 33 in a manner that can move up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com