High strength slim diamond blade

A diamond saw blade, high-strength technology, used in gems, diamond tools, glass, graphite processing industries, and ceramic fields, can solve problems such as the difficulty of shaping the saw blade substrate, the development restriction of brazed diamond thin saw blades, and the insufficient strength of the thin substrate. , to achieve the effect of improving strength and adapting to a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

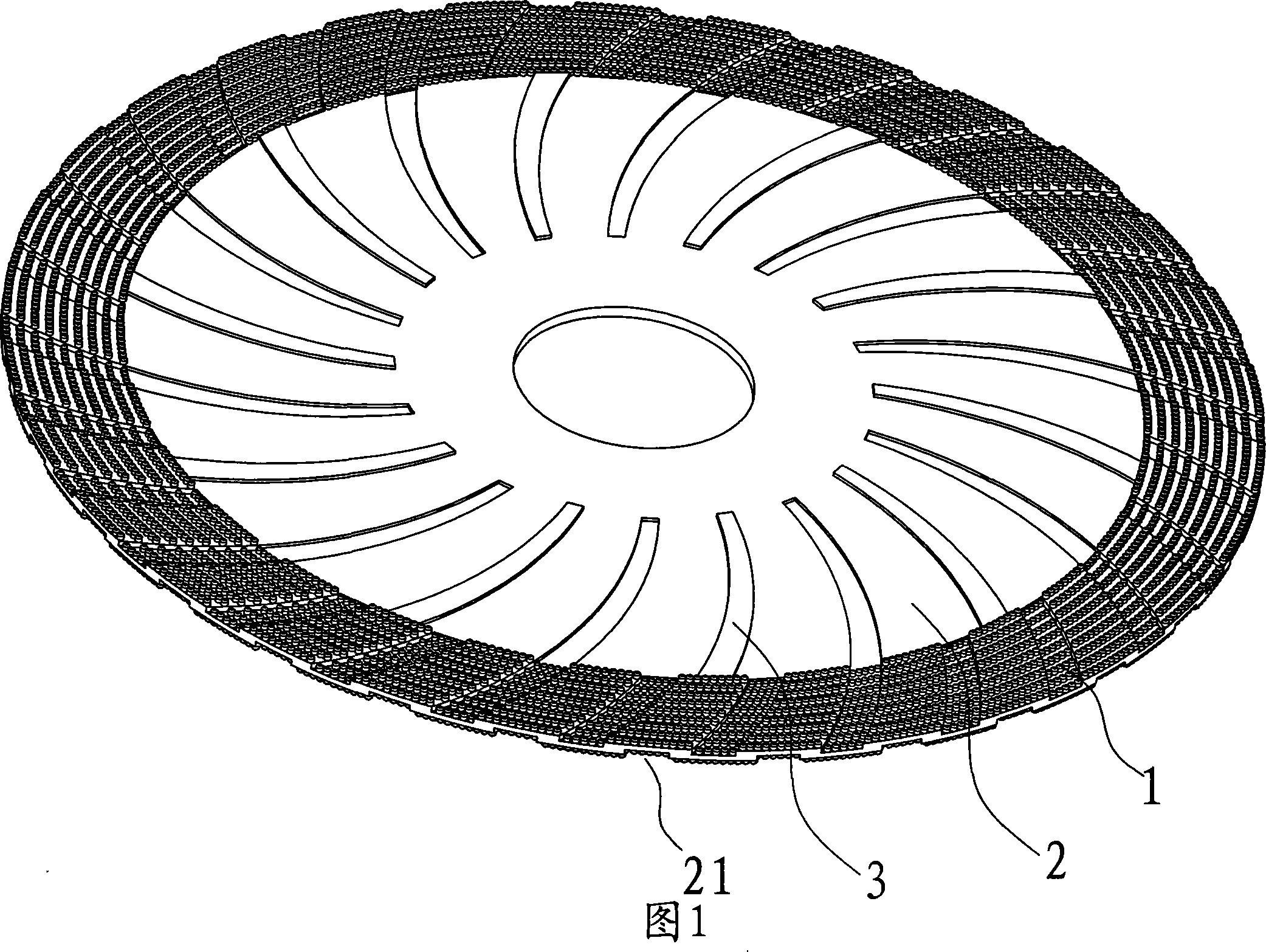

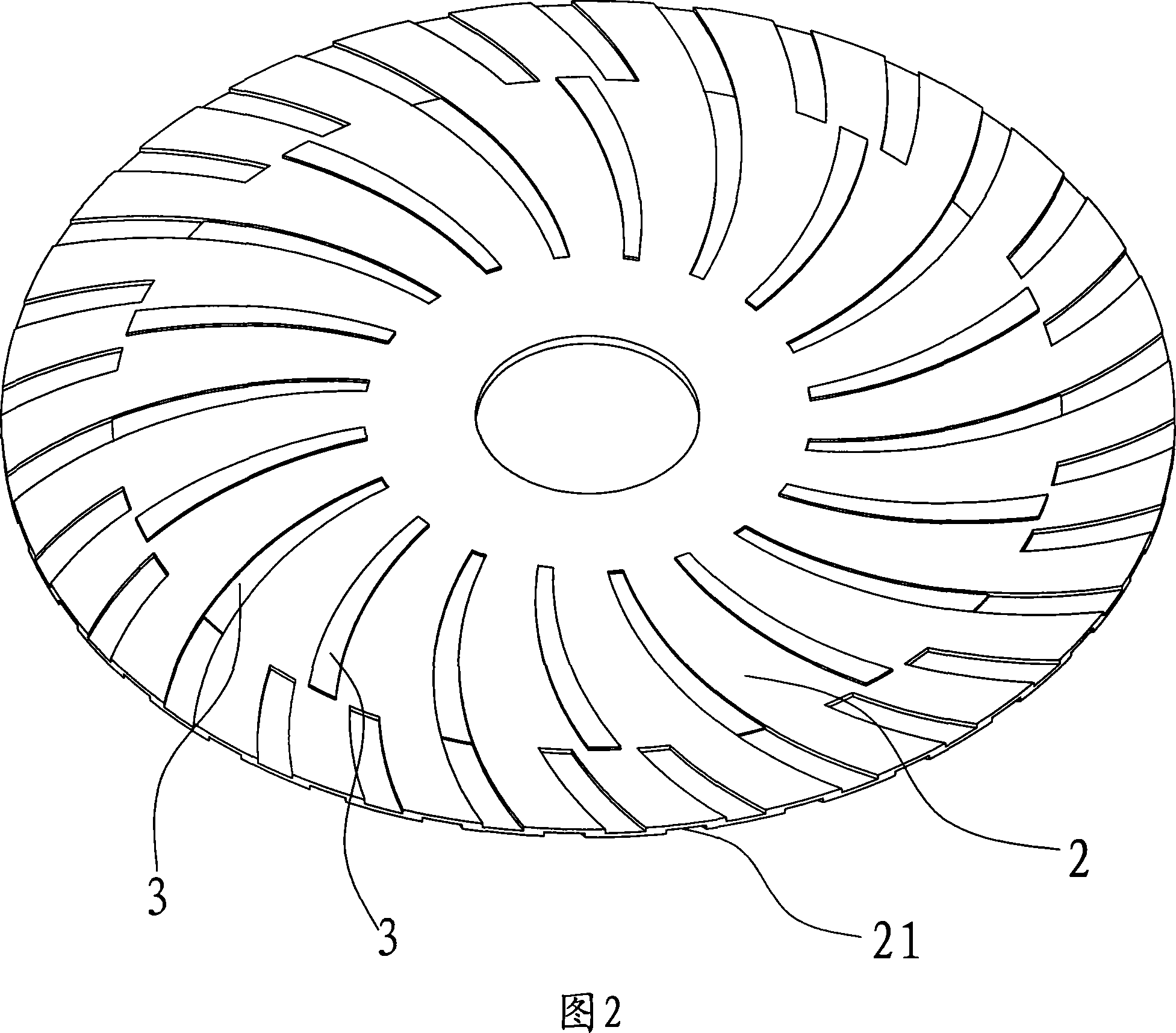

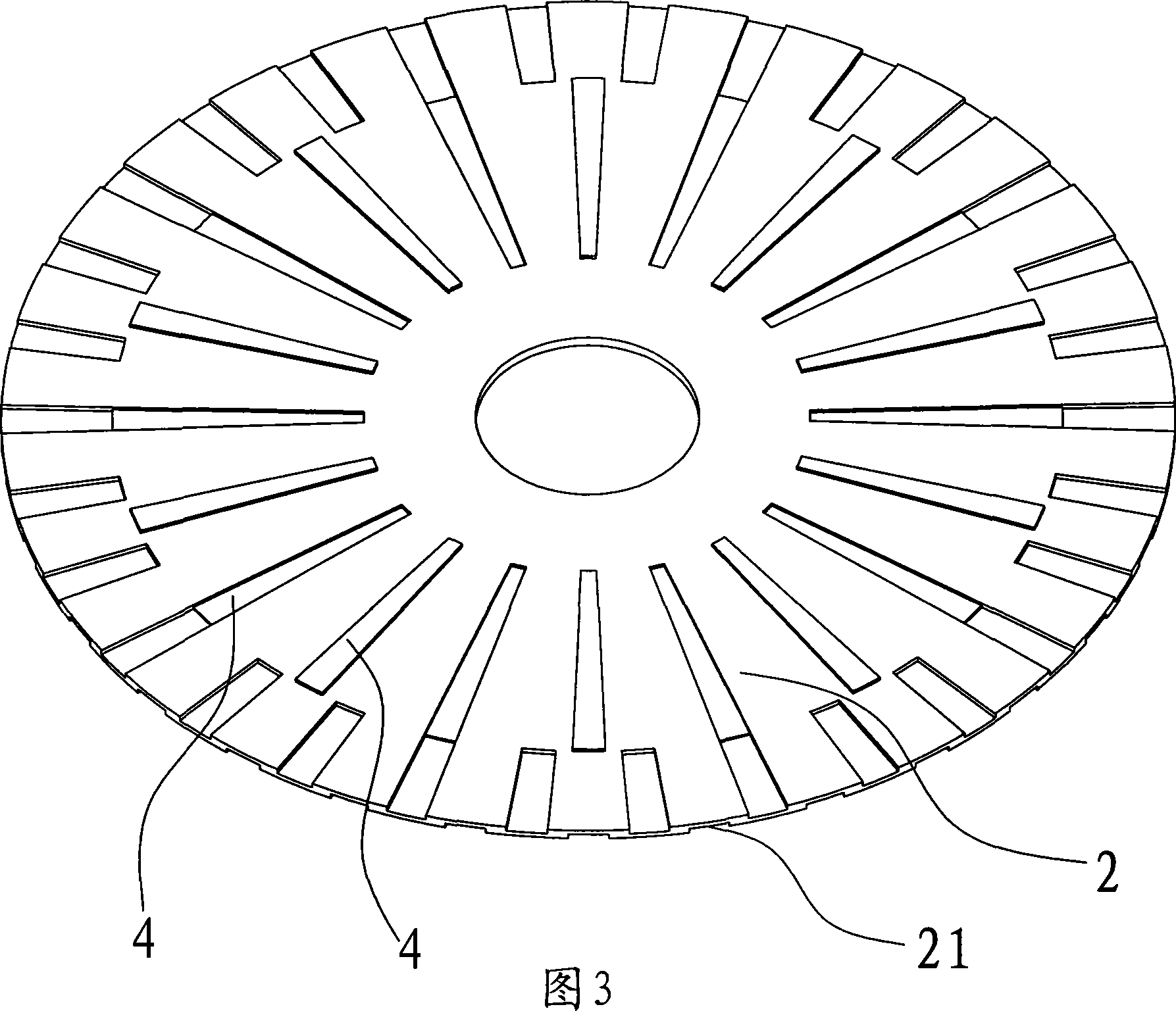

[0016] The new high-strength ultra-thin diamond saw blade of the present invention, embodiment 1 is shown in Figure 1, 2, and the diameter of diamond saw blade is 10MM-400MM, including diamond abrasive grain 1 and the thickness at the center hole flange (i.e. the original thickness of the metal substrate) The ultra-thin metal substrate 2 is 0.1mm-1mm. The diamond abrasive grains 1 are fixed in the tooth grooves 21 of the metal substrate 2 by brazing or electroplating and arranged along the length direction of the tooth grooves 21. The diamond abrasive grains 1 can also pass through It is fixed on the periphery of the alveolar 21 of the metal base 2 by means of brazing or electroplating. Both sides in the thickness direction of the metal base 2 are respectively shaped to form reinforcing ribs 3 that are uniformly distributed from one side in the thickness direction of the metal base 2 to the other side and make the other side protrude. In this embodiment, The reinforcing rib 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap