Independent wheel direct single axis bogie flexible coupling radial adjusting agency

A technology of adjusting mechanism and bogie, which is applied in the self-adjustment of wheel axles, railway couplings, railway car body parts, etc. It can solve the problems of steel spring stability, affecting the normal operation of springs, and troublesome implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

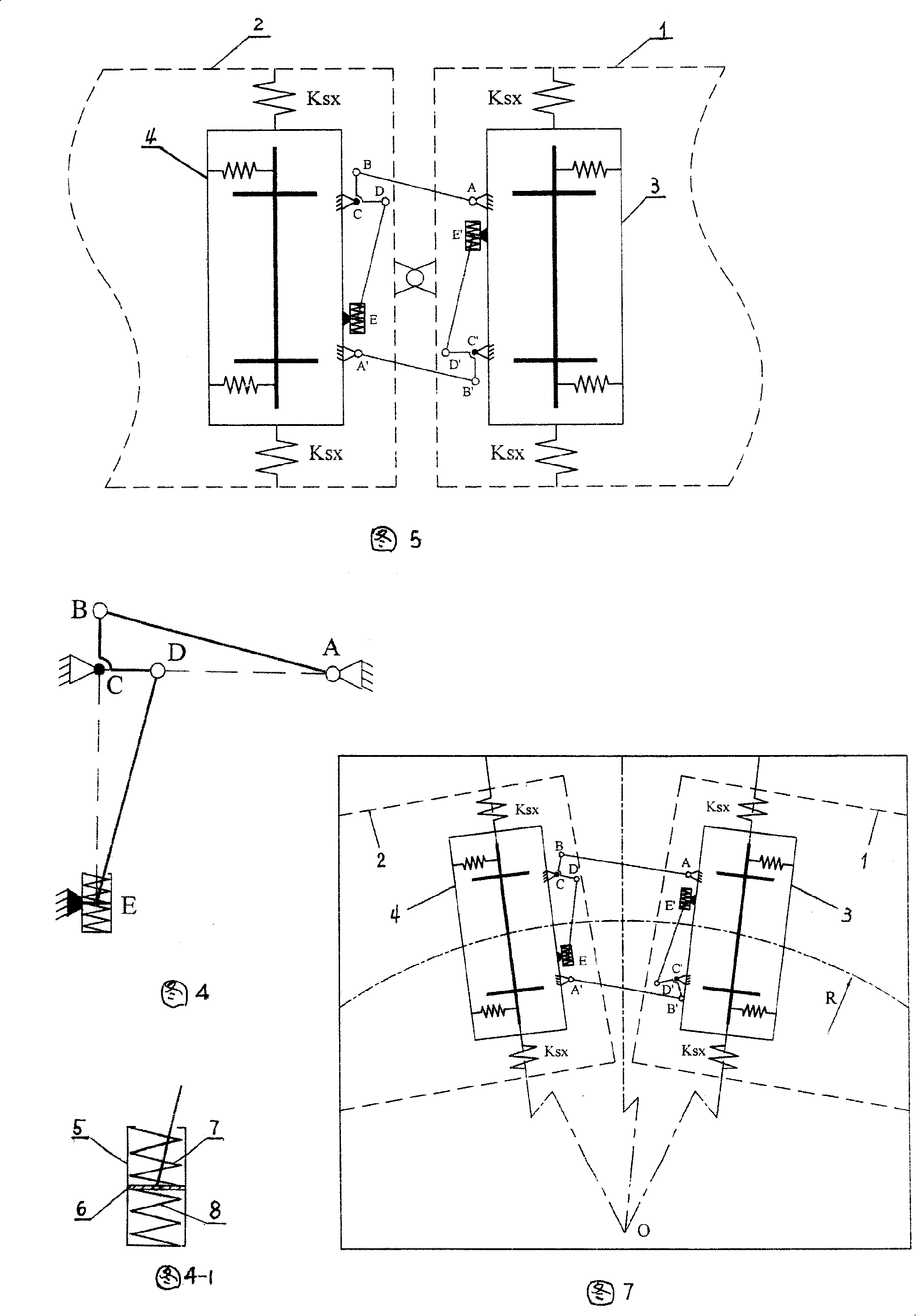

[0049] Figure 4 and Figure 4-1 show that a single elastic coupling mechanism consists of a right-angle arm BCD, a connecting rod AB, a connecting rod DE and a spring device. Wherein the spring device is made up of cylinder barrel 5 (including cylinder head), piston 6 and two springs 7,8 again. The two springs 7 and 8 in the compressed state are respectively placed in the upper and lower cylinder barrel spaces of the piston 6 . Referring to Fig. 5, during installation, the front and rear independent wheel pairs under the adjacent ends of the front and rear car bodies 1 and 2 of the train adopt single-axle bogies, and between the front and rear single-axle bogies 3, 4, before 1. Two identical elastic coupling mechanisms are arranged in such a manner that the hinge points of the rear vehicle body are symmetrical to the center. The structure of a single elastic coupling mechanism is as follows: point C of the right-angle swivel arm BCD is pinned to the rear single-axis bogie 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com