Back light module unit and lcd device

一种背光模组、混光的技术,应用在光学、非线性光学、静态指示器等方向,能够解决背光模组混光效果差、厚度大等问题,达到混光效果好、厚度小、显示品质好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

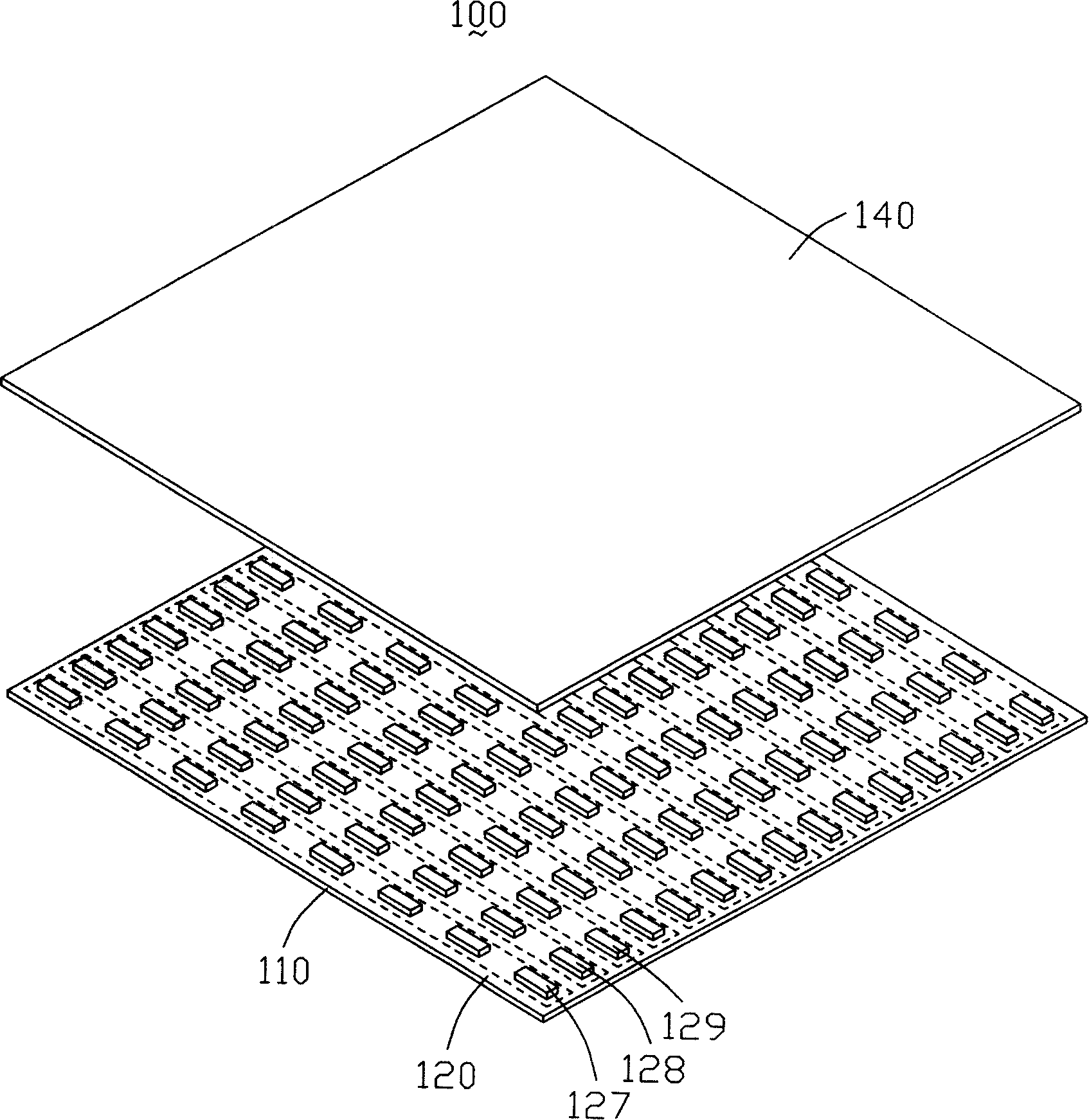

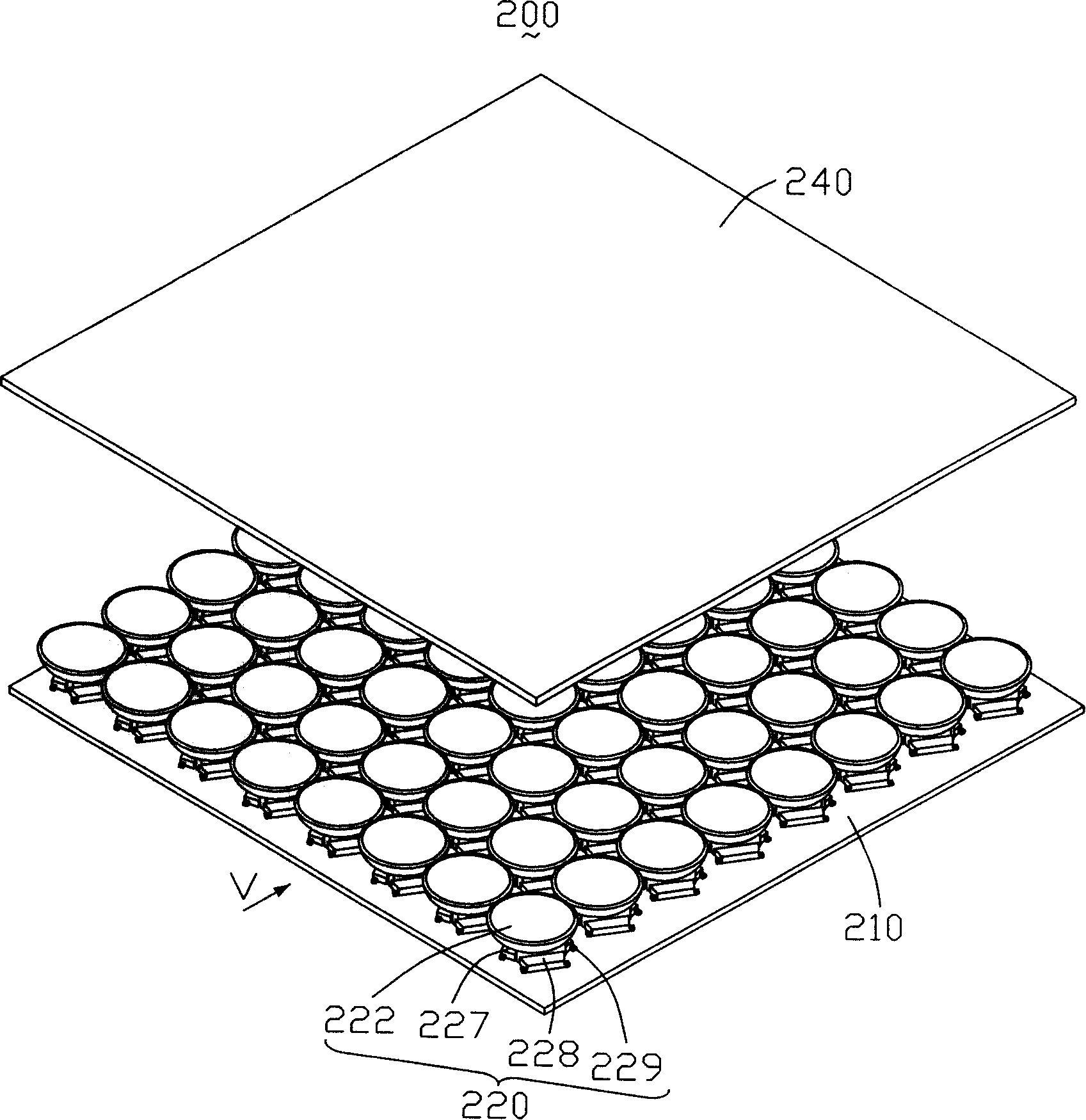

[0022] see figure 2 , is a schematic perspective view of the first embodiment of the backlight module of the present invention. The backlight module 200 is a direct type backlight module, which includes a base plate 210 , a plurality of light emitting units 220 arranged in an array on the base plate 210 and a diffuser plate 240 disposed above the base plate 210 . The light emitting unit 220 includes a red light emitting diode 227 , a green light emitting diode 228 , a blue light emitting diode 229 and a light mixer 222 .

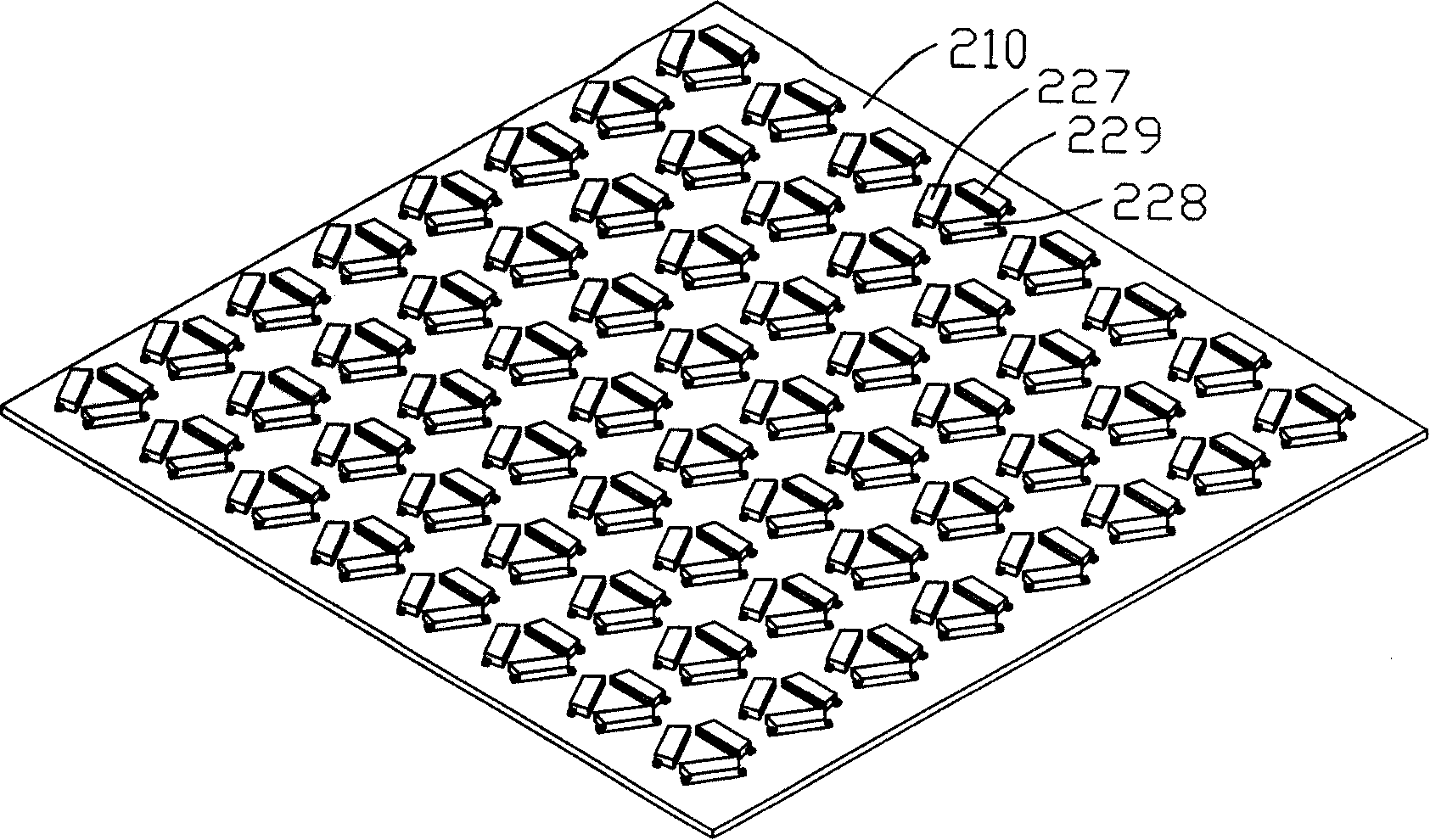

[0023] see image 3 , Figure 4 with Figure 5 , image 3 is the arrangement diagram of the red, green and blue light emitting diodes 227, 228, 229, Figure 4 is a schematic perspective view of the light mixer 222, Figure 5 A side view of the light emitting unit 220 along the V direction.

[0024] The red, green and blue LEDs 227, 228 and 229 are adjacent to each other to form a triangular area. The light mixer 222 includes three light guide rods 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com