Control of fluid conditions in bulk fluid distribution systems

A distribution system and fluid technology, applied in the direction of liquid distribution, transportation or transfer device, distribution device, special distribution device, etc., can solve the problems of reduced fluid pressure and increased pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

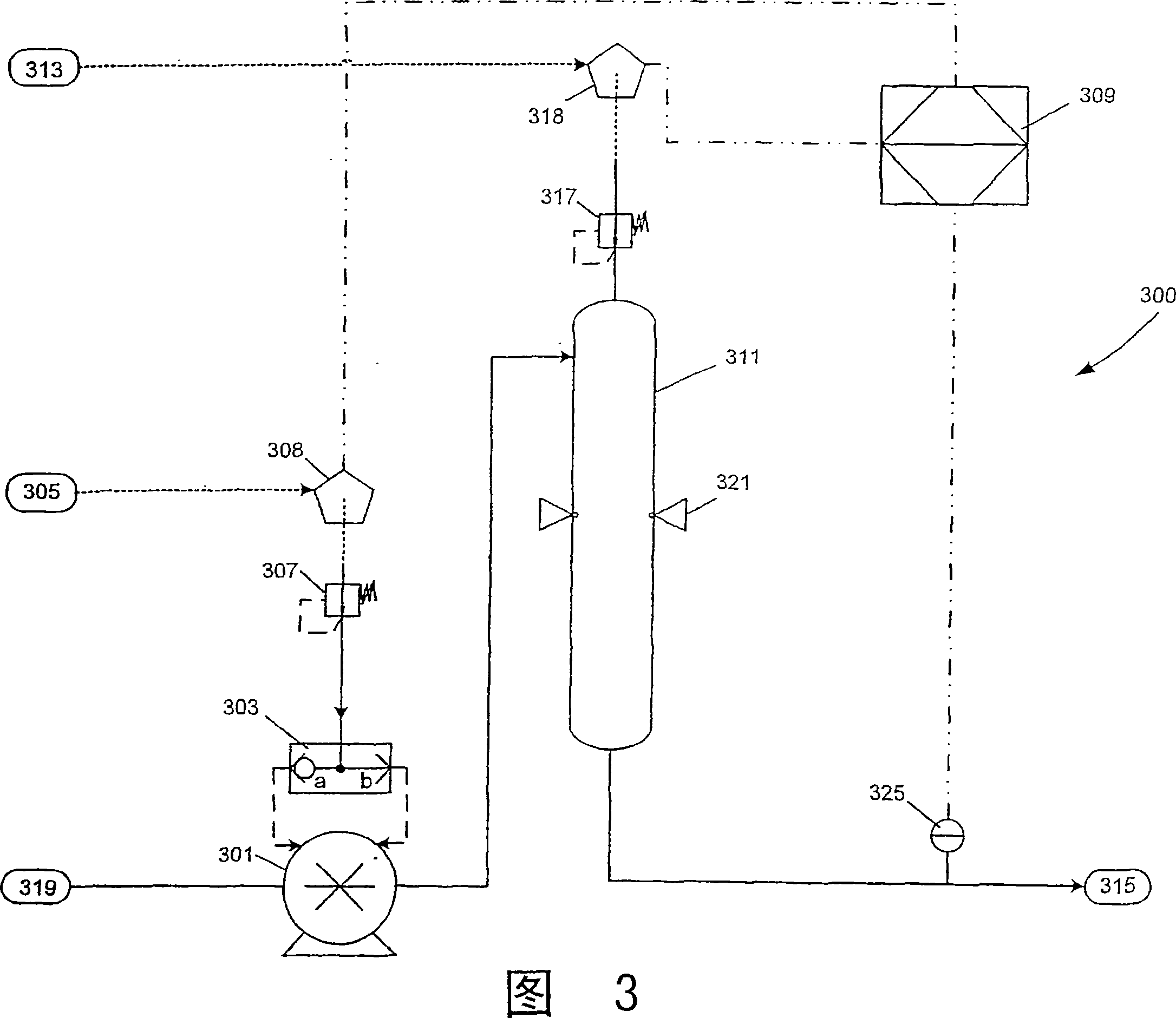

[0023]Figures 3 and 4 show embodiments of the present invention. The invention presents a fluid dispensing system with a pump-based motor that provides constant control over the pressure and flow conditions of fluid in a volumetric fluid supply line. Figure 3 shows an embodiment of a pump-pressure vessel system 300 according to the present invention. System 300 includes a pump 301 (eg, a reciprocating pump, a pneumatic double diaphragm pump, or other type of positive displacement pump) having a shuttle valve 303 . Shuttle valve 303 may be an external shuttle valve or an internal shuttle valve. A high pressure gas source 305 such as clean dry air supplies gas to a pair of solenoid valves 303 a and 303 b in the shuttle valve 303 . A master regulator 308 (eg, an electro-pneumatic regulator) and a slave regulator 307 (eg, a dome-load pressure regulator) are used to control and regulate the pressure of the high pressure gas supplied to the shuttle valve 303 . The master regulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com