Ball sliding rail

一种滚珠滑轨、滚珠架的技术,应用在轴承、直线运动的轴承、家具零件等方向,能够解决轨体难插入、损坏滚珠架等问题,达到方便插入、不易损坏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

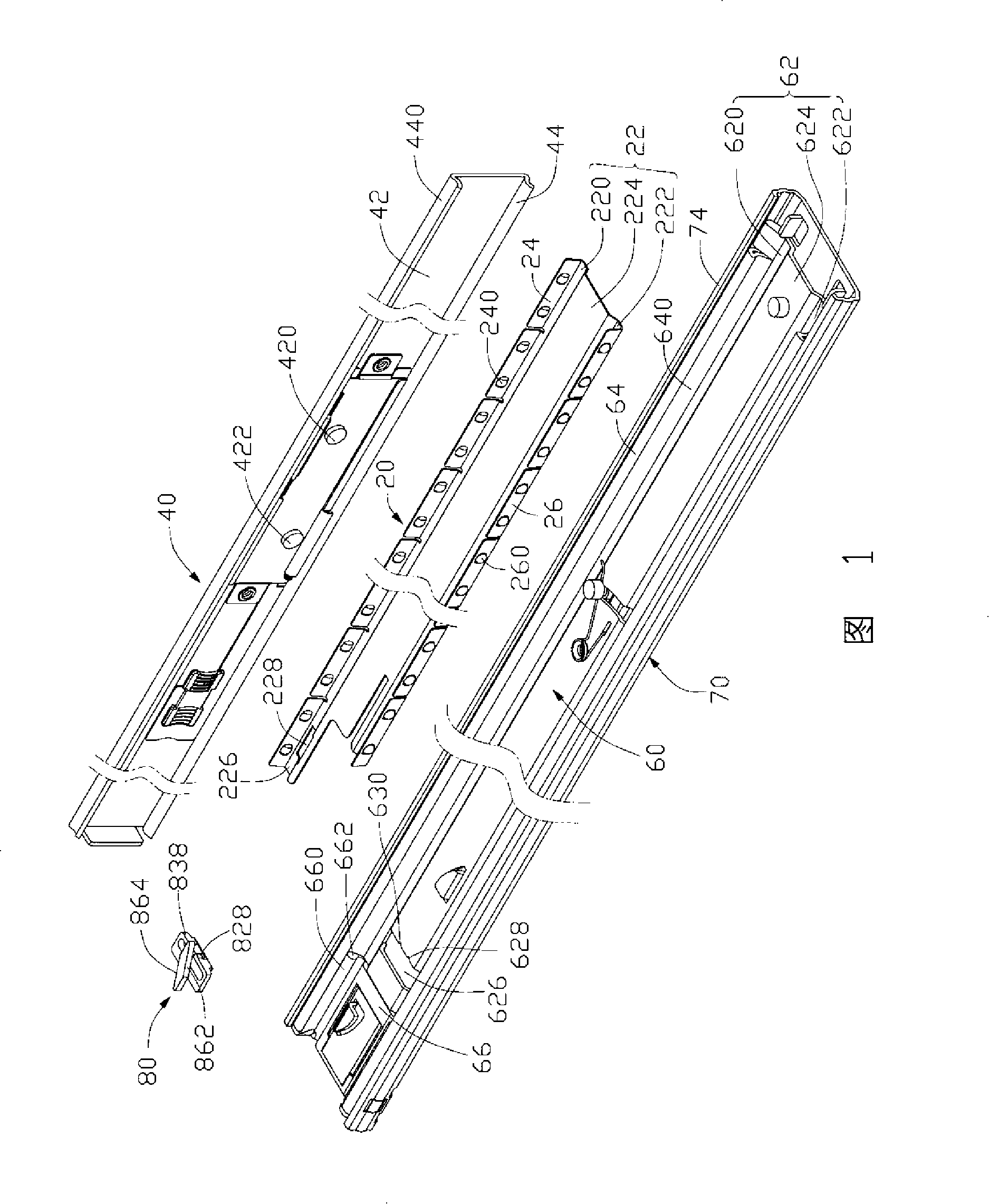

[0012] Please refer to Fig. 1 to Fig. 3, it is a preferred embodiment of the ball slide rail of the present invention, which includes a ball rack 20, a first rail 40, a second rail 60 set on the first rail 40, a set on the The third rail 70 of the second rail 60 and a positioning member 80 . The ball rack 20 is arranged between the first rail 40 and the second rail 60 for assisting the sliding of the first rail 40 relative to the second rail 60; Positioned on the second rail 60 .

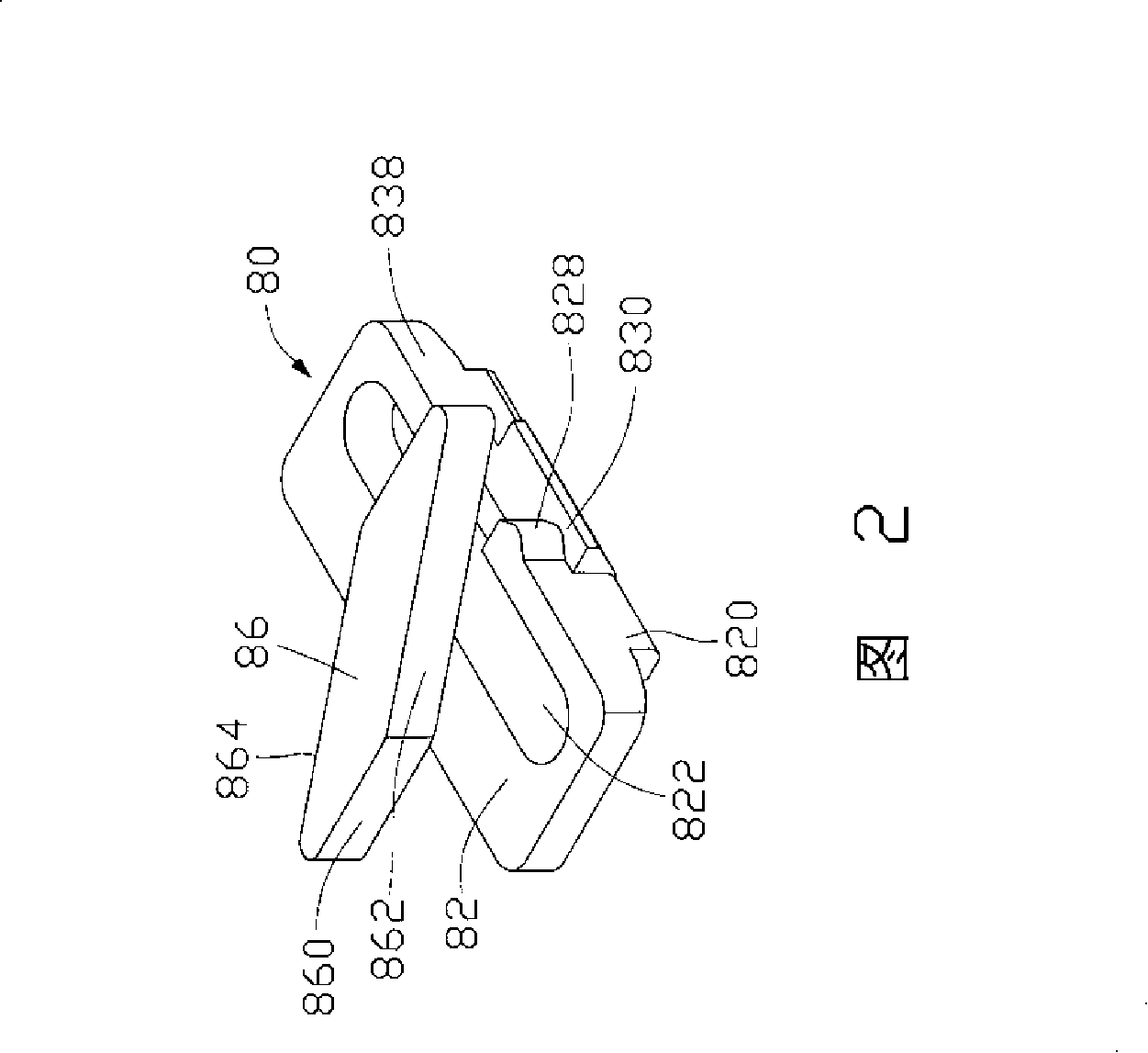

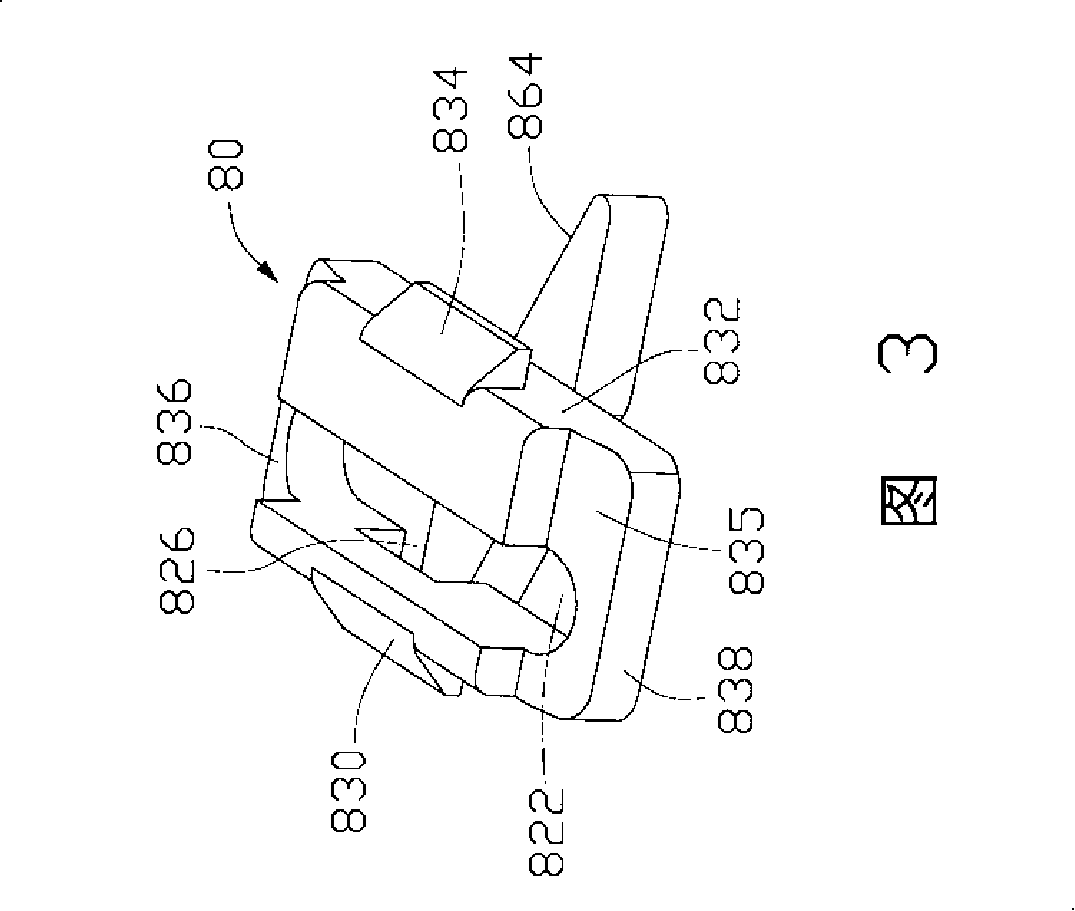

[0013] The positioning member 80 is made of plastic or other elastic materials, and includes a base 82 and an abutting portion 86 integrally formed. The base 82 is roughly a cuboid, and a slot 822 is provided near the side wall 820, and a depression 826 communicating with the slot 822 is provided on the side wall 820; Block 828, on the side wall 820 adjacent to the bottom of the recess 826 protrudes outwards a protrusion 830, the upper surface of the protrusion 830 is flat and flush with the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com