Method for hot-filling a thin-walled container

A hot filling, container technology, applied in the direction of liquid filling, thin material handling, packaging item type, etc., can solve problems such as heavy weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

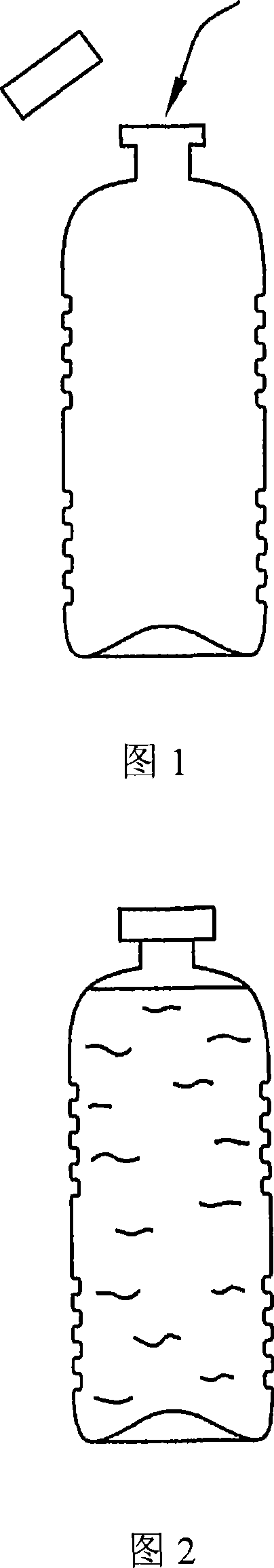

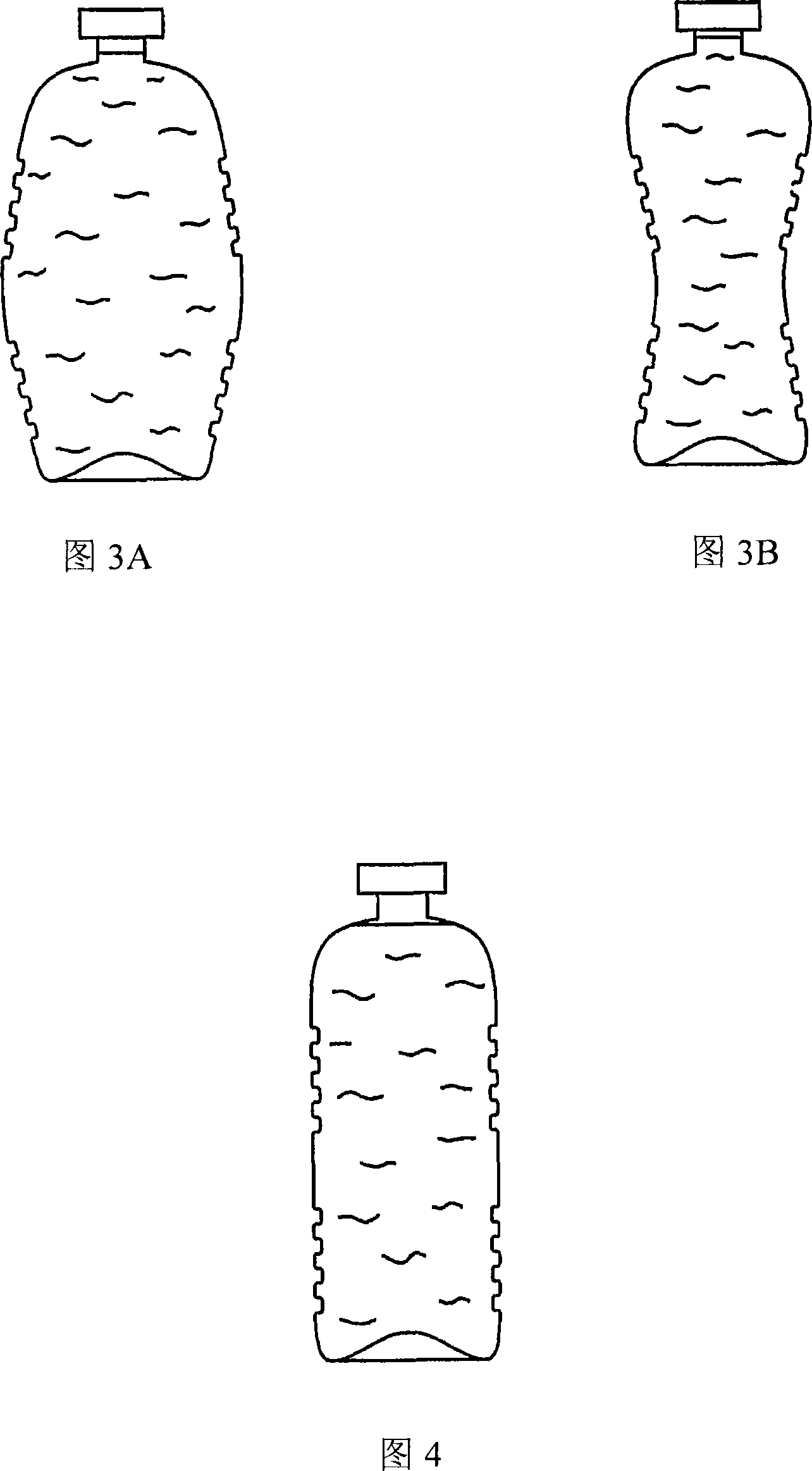

[0061] The examples given relate to bottles made of PET material, but can be applied to containers made of polymeric material all of the same nature and exhibiting similar characteristics.

[0062] The method involves hot filling a thin-walled container having the characteristics described below.

[0063] The container is cylindrical and may have grooves to strengthen the bottle body. It may have a thin bottom, such as containing still mineral water, and may also have a reinforced bottom. The total weight of the container is basically the same as that of the container used to hold mineral water. Quite equal in volume.

[0064] Reinforced bottoms generally consist of a bottom raised towards the neck of the bottle with stiffeners to avoid tipping over under light pressure.

[0065] The container can be manufactured using either of two processing methods known as "HR", single or double, depending on the temperature of the package.

[0066] Thus, the container is resistant to hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com