Bone strengthening milk powder and producing method thereof

A production method and technology of milk powder, applied in the directions of milk preparations, dairy products, applications, etc., can solve the problem of not producing and developing functional food, etc., and achieve the effects of inhibiting the growth of osteoclasts, increasing bone density, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The raw material formula of the milk powder of the present embodiment: milk 6500kg, CBP powder (New Zealand Shihuali Co., Ltd. production) 0.5kg, calcium powder (milk calcium) 1kg.

[0034] The production method of the milk powder of the present embodiment mainly comprises the following steps:

[0035] 1. Raw milk (raw milk, raw milk) acceptance inspection, clean milk: It is required that the fat, protein, dry matter, freshness and other indicators meet the quality standards of raw milk, and the mechanical impurities in the raw milk are removed through the clean milk process ;

[0036] 2. Ingredients: Add calcium powder to the raw milk, stir properly to fully dissolve the calcium powder, and then pass the feed liquid through a homogenizer for homogenization, with a homogenization pressure of 10-25MPa and a homogenization temperature of 40-55°C;

[0037] 3. The homogenized material is sterilized and concentrated, and discharged when the concentration of the material rea...

Embodiment 2

[0056] The raw material formula of the milk powder of this embodiment: 9000 kg of milk, 15 kg of CBP powder, 8 kg of calcium powder (organic calcium), and 10 kg of soybean lecithin (purchased from Guangdong Haisheng Biotechnology Co., Ltd.).

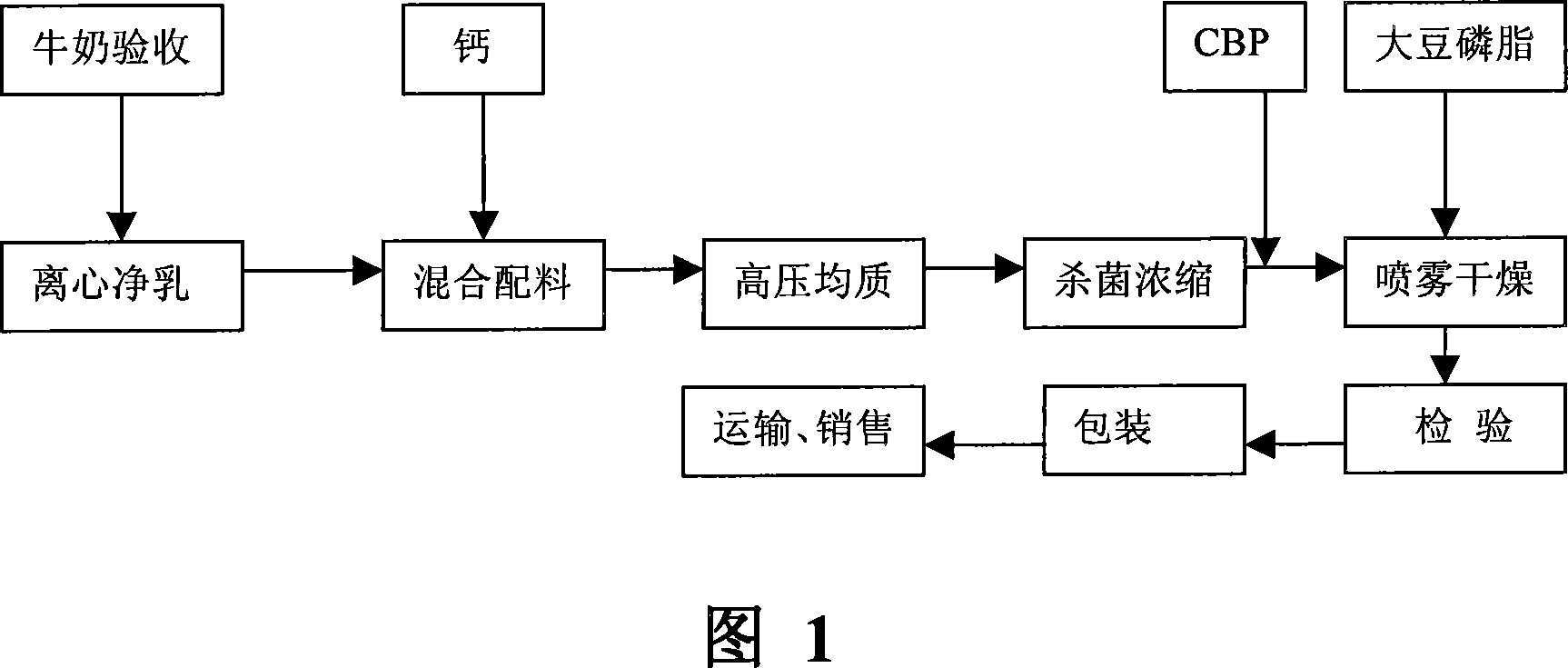

[0057] The production process of the milk powder of the present embodiment can refer to Fig. 1, mainly comprises the following steps:

[0058] 1. The steps of acceptance of raw milk, milk cleaning→mixing ingredients (adding calcium powder)→homogenizing→sterilizing and concentrating→adding CBP are basically the same as in Example 1, and the concentrated feed liquid containing CBP is obtained;

[0059] 2. The concentrated feed solution containing CBP is spray-dried, and the powder spraying parameters are basically the same as in Example 1. After powder spraying, soybean lecithin was sprayed on a fluidized bed, dried, powdered, inspected and packaged to obtain the milk powder of this embodiment.

Embodiment 3

[0061] The raw material formula of the milk powder of the present embodiment: milk 8500kg, CBP powder 1kg, calcium powder 7.5kg, soybean lecithin 5kg.

[0062] The production technology of the milk powder of the present embodiment is basically the same as embodiment 2.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap