Heating picking process for promoting cement kiln residual heat generating efficiency

A waste heat power generation and thermal process technology, used in waste heat treatment, lighting and heating equipment, heating to dry solid materials, etc. Reduce capital and electricity costs, improve performance curves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

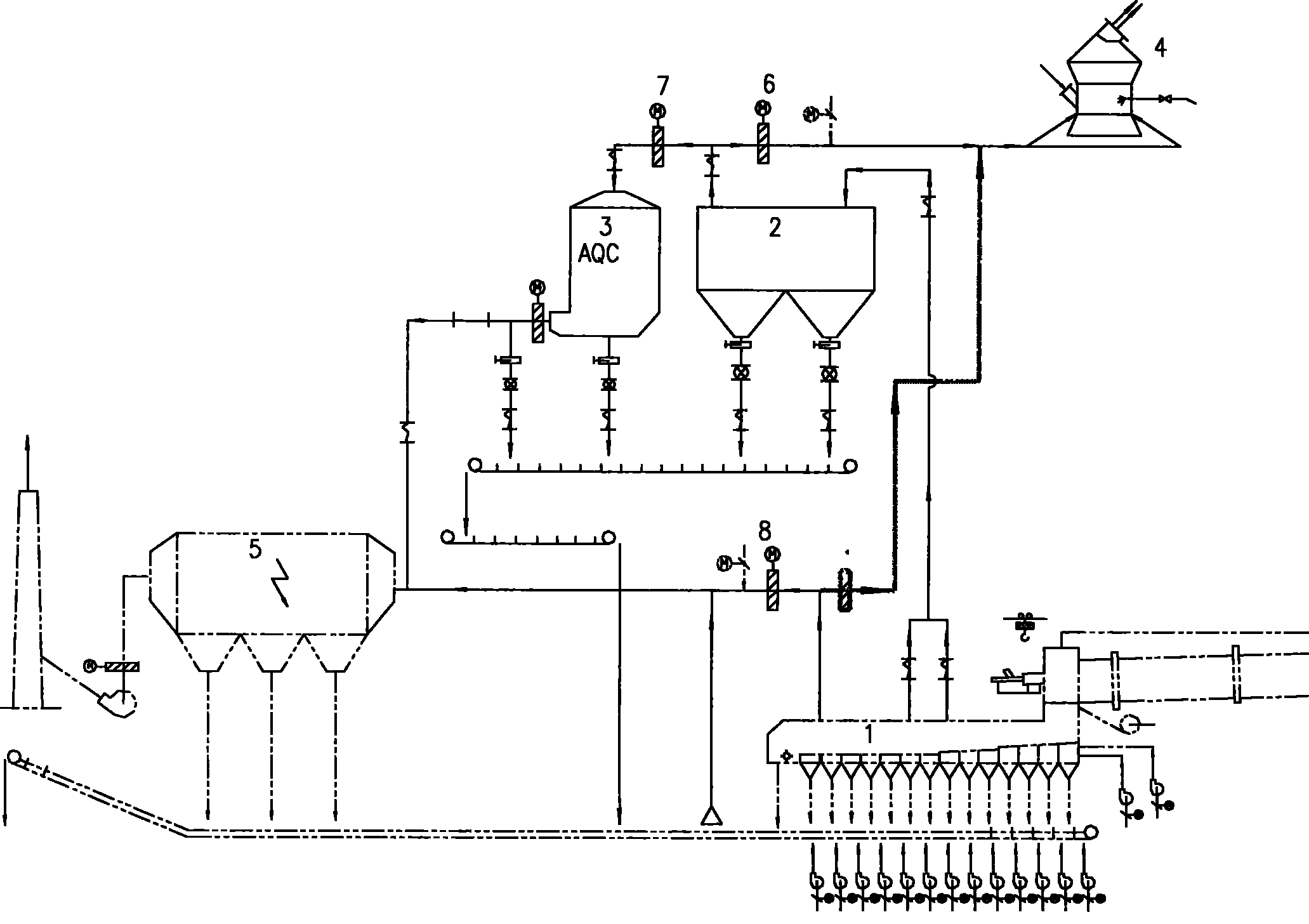

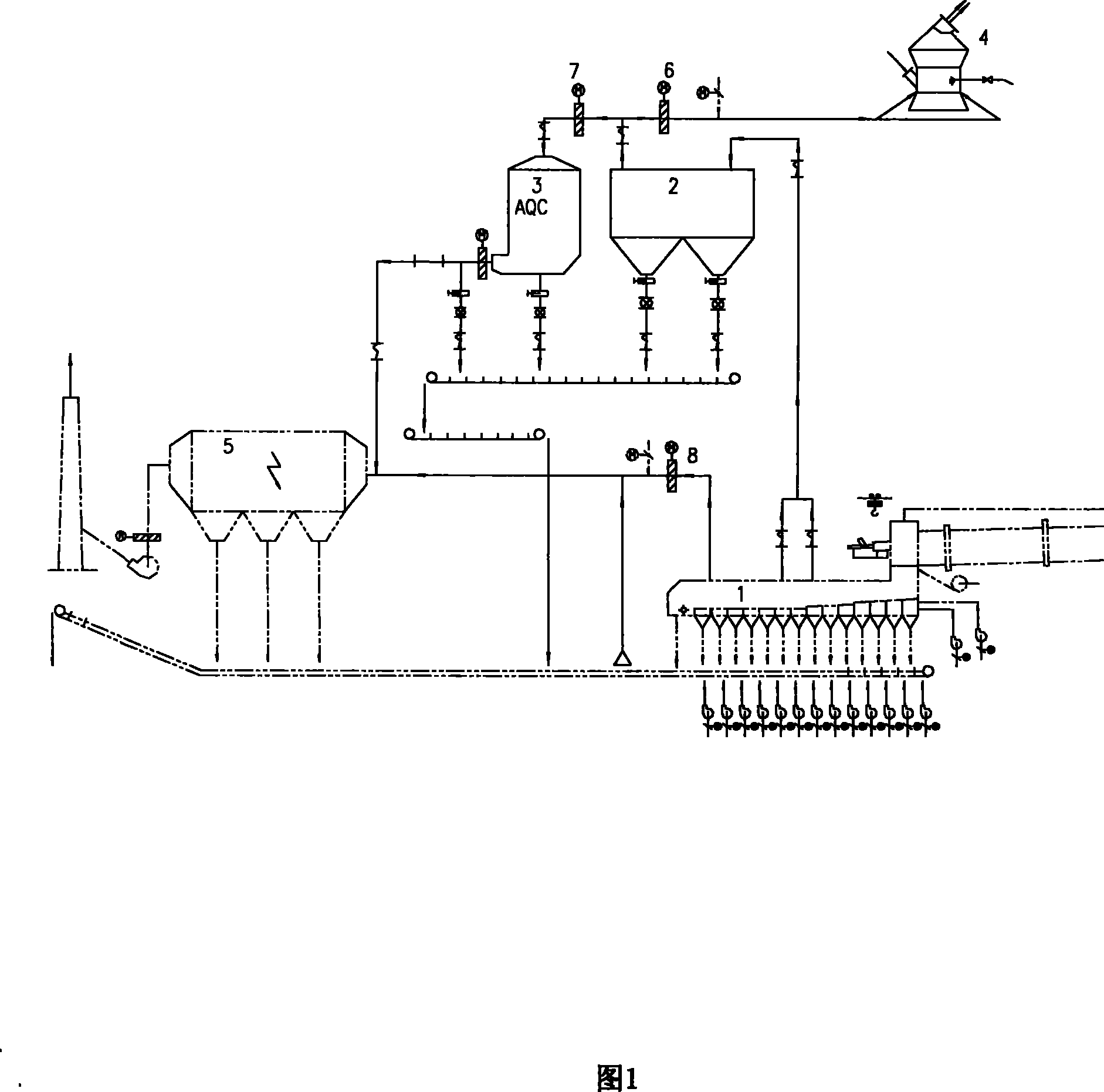

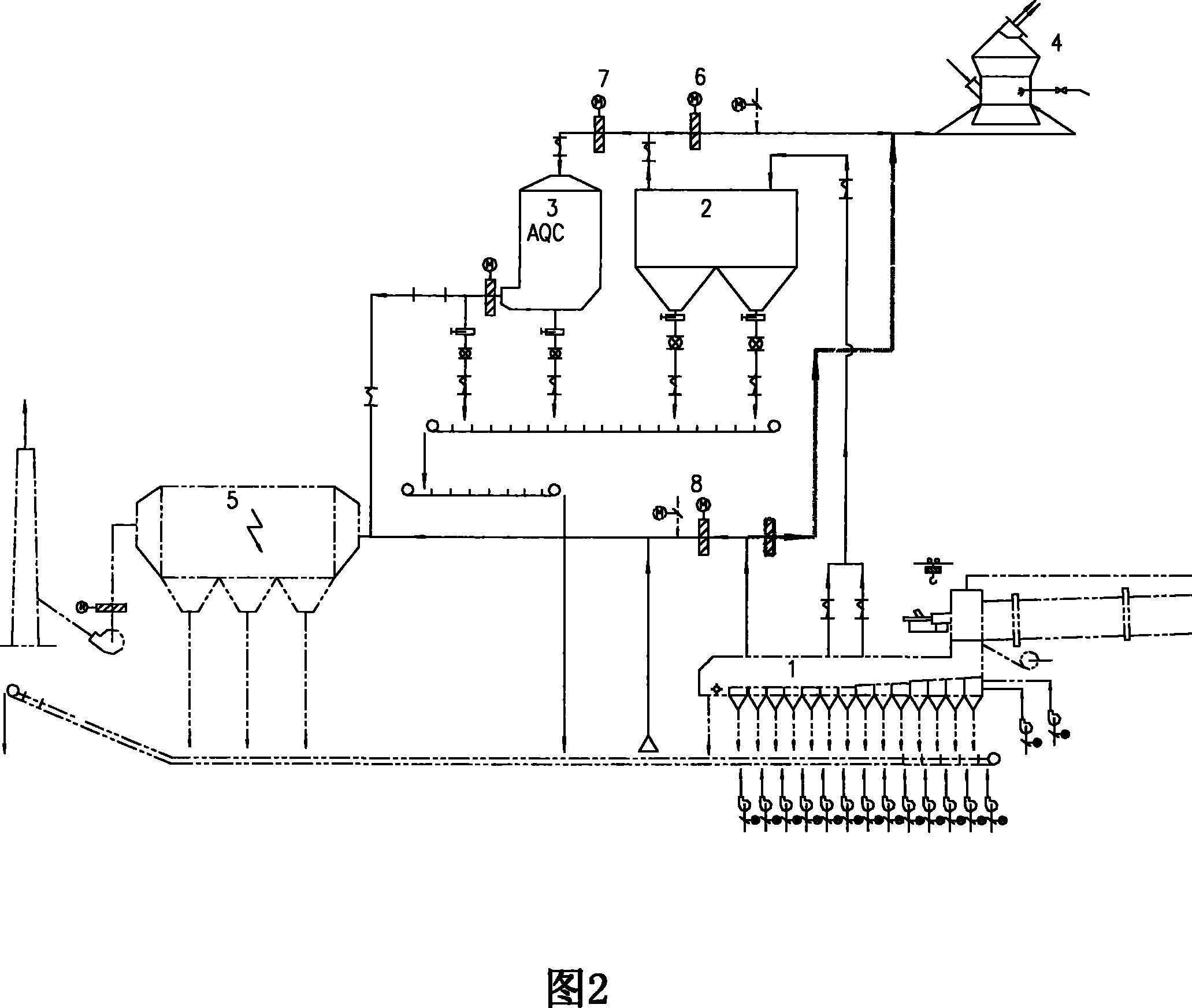

[0027] As shown in Figure 2: This heat extraction process to improve the efficiency of cement kiln waste heat power generation is to mix the remaining low-temperature air at about 150°C at the tail of the grate cooler with medium-temperature waste gas at 380-450°C according to the demand for raw coal, and then send Go to the coal mill for drying raw coal; the steps are as follows:

[0028] 1. Near the low-temperature flue remaining air pipe at the tail of the grate cooler, open the low-temperature air pipe leading out of the coal mill and set a first high-temperature regulating valve 9 on it; The medium-temperature air pipe leading out of the middle part with the second high-temperature regulating valve 6 to the coal mill is connected, and then enters the coal mill system;

[0029] 2. During production, a moisture analysis instrument is installed at the feed port of the coal mill. According to the moisture content of the raw coal, adjust the first high-temperature regulating v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com