Explosive friction sensitivity instrument

A technology of sensitivity meter and explosives, which is applied in the field of explosive performance testing devices, can solve the problems of difficult to guarantee test conditions, low test accuracy, and low degree of automation, and achieve the effects of wide application range, firm installation, and good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

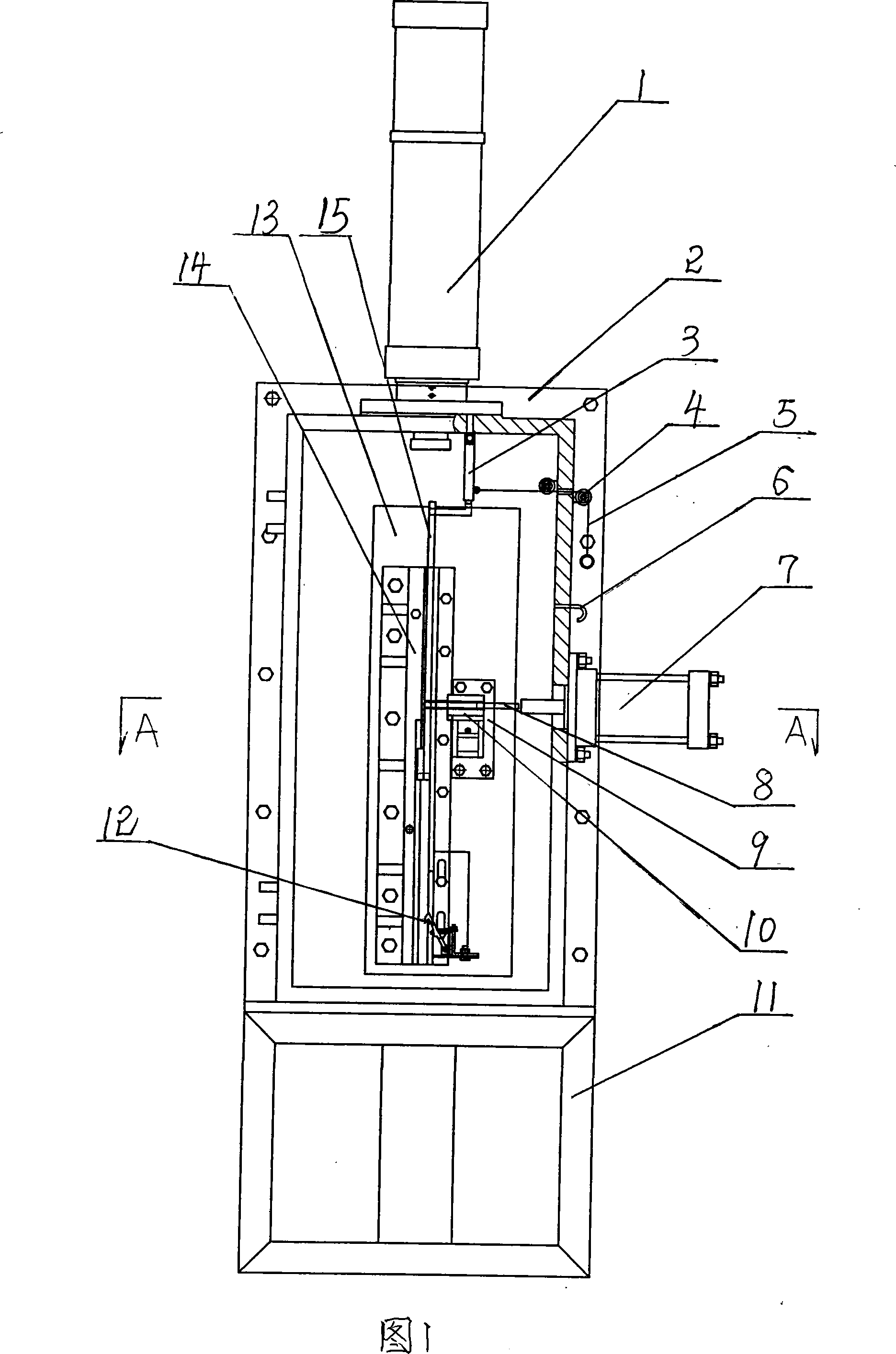

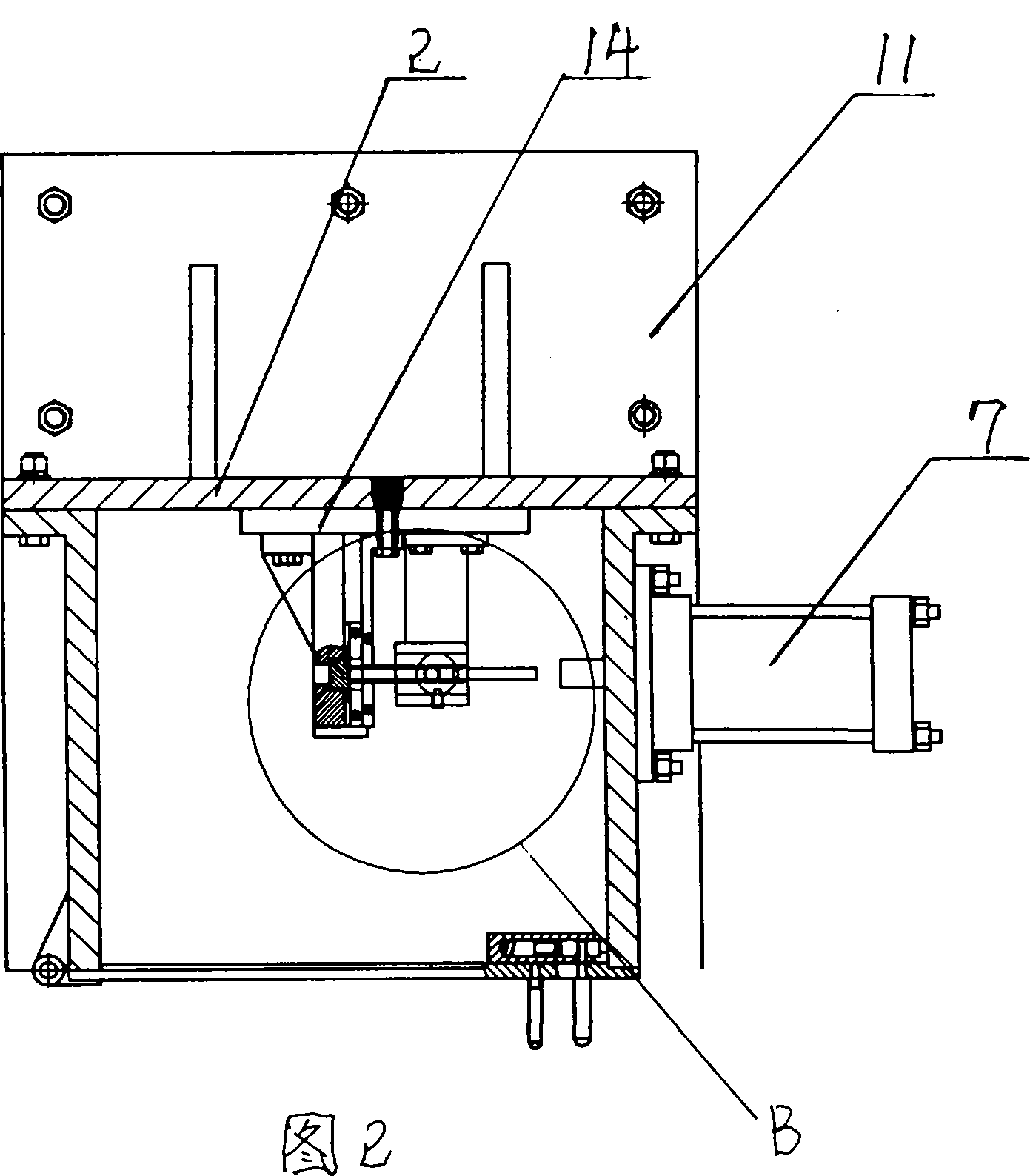

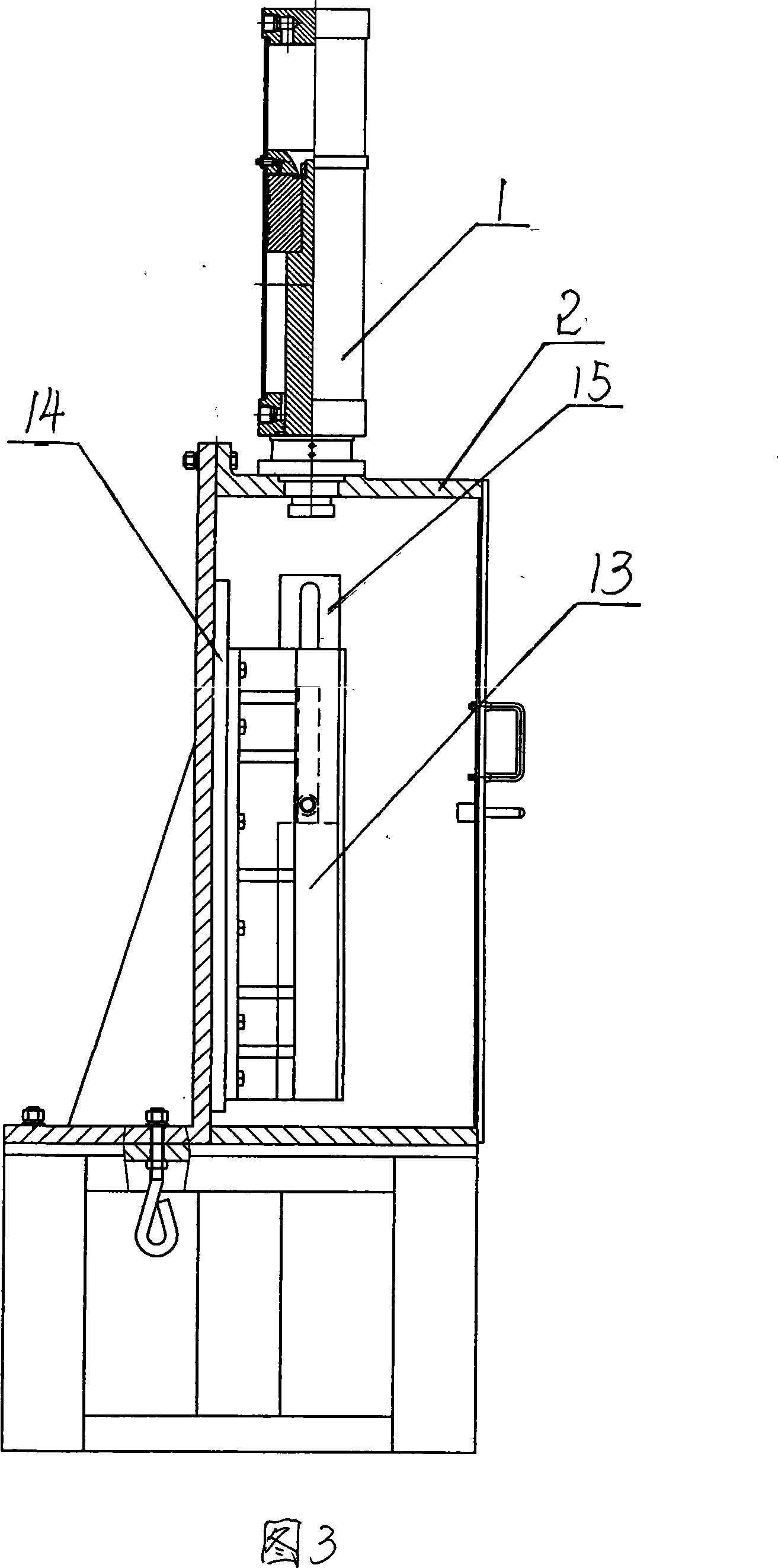

[0041] Such as figure 1 to combine figure 2 with Figure 4Shown schematically, a kind of explosive friction sensitivity instrument comprises box body 2, and the inner wall of one side in box body 2 is fixed with belt clamp support frame 14, is inserted on belt clamp support frame 14 and is inserted with friction belt clamp 15, and the top of friction belt clamp 15 There is an impact cylinder 1 fixed on the upper side wall of the box, and a sample support seat 9 with a rotary hole is fixed on one side of the support frame 14 with a clamp. The support seat 10, the hole of the support seat 10 is interspersed with an explosive clamping tube 20, the explosive clamping tube 20 is pierced with a push rod 8, one end of the push rod 8 corresponds to the friction belt clamp 15, and the other end of the push rod 8 is fixed to the The pre-tightening cylinder 7 on the side of the casing is top connected.

[0042] The support base 10 can rotate in the rotary hole on the sample support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com