Flying disk

A flying saucer and flywheel technology, applied in the field of aircraft, can solve the problems of high maintenance and use cost, complicated air flight control, high energy consumption, etc., and achieve the effects of fast or slow speed, improved flying saucer power, and increased propulsion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

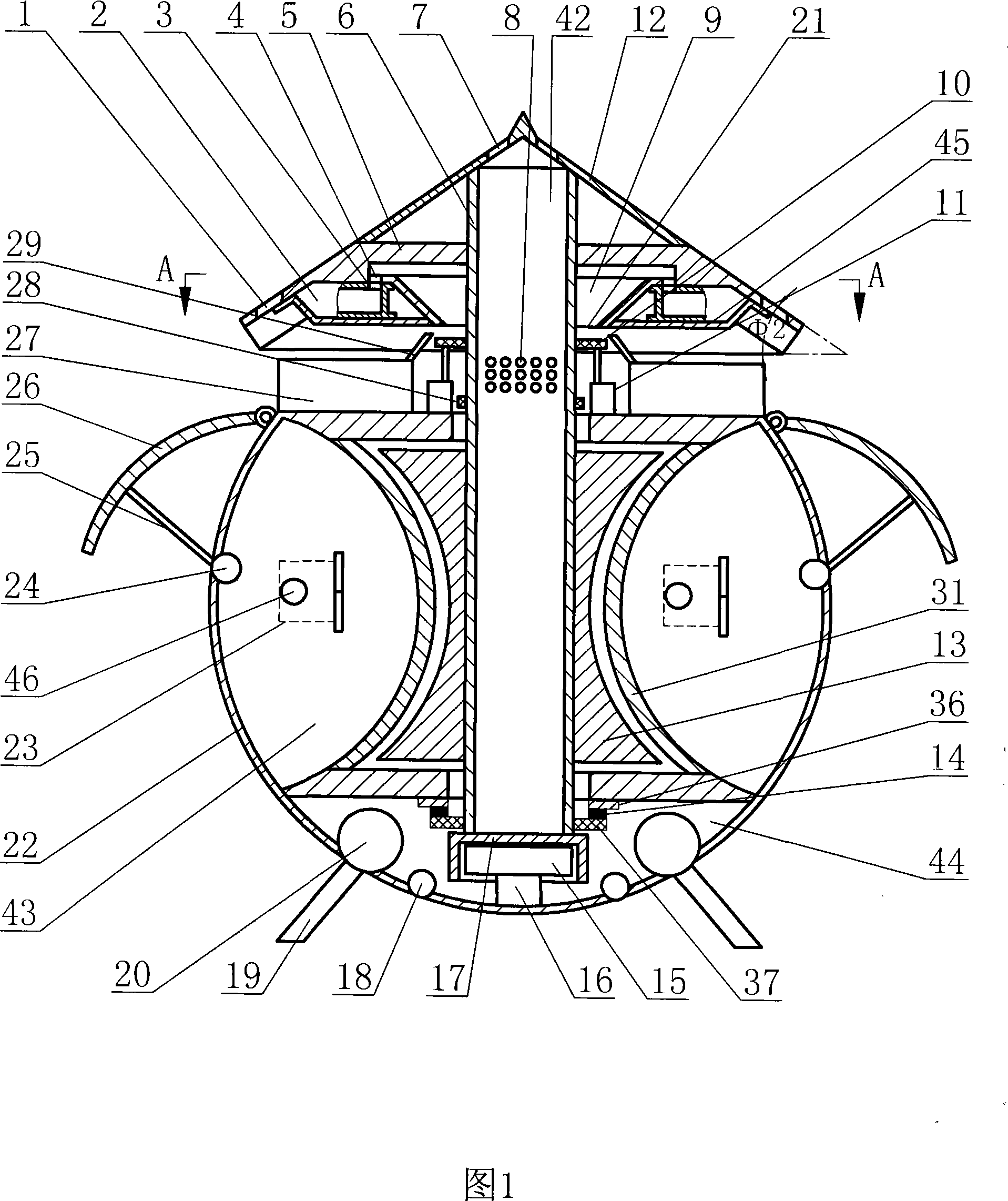

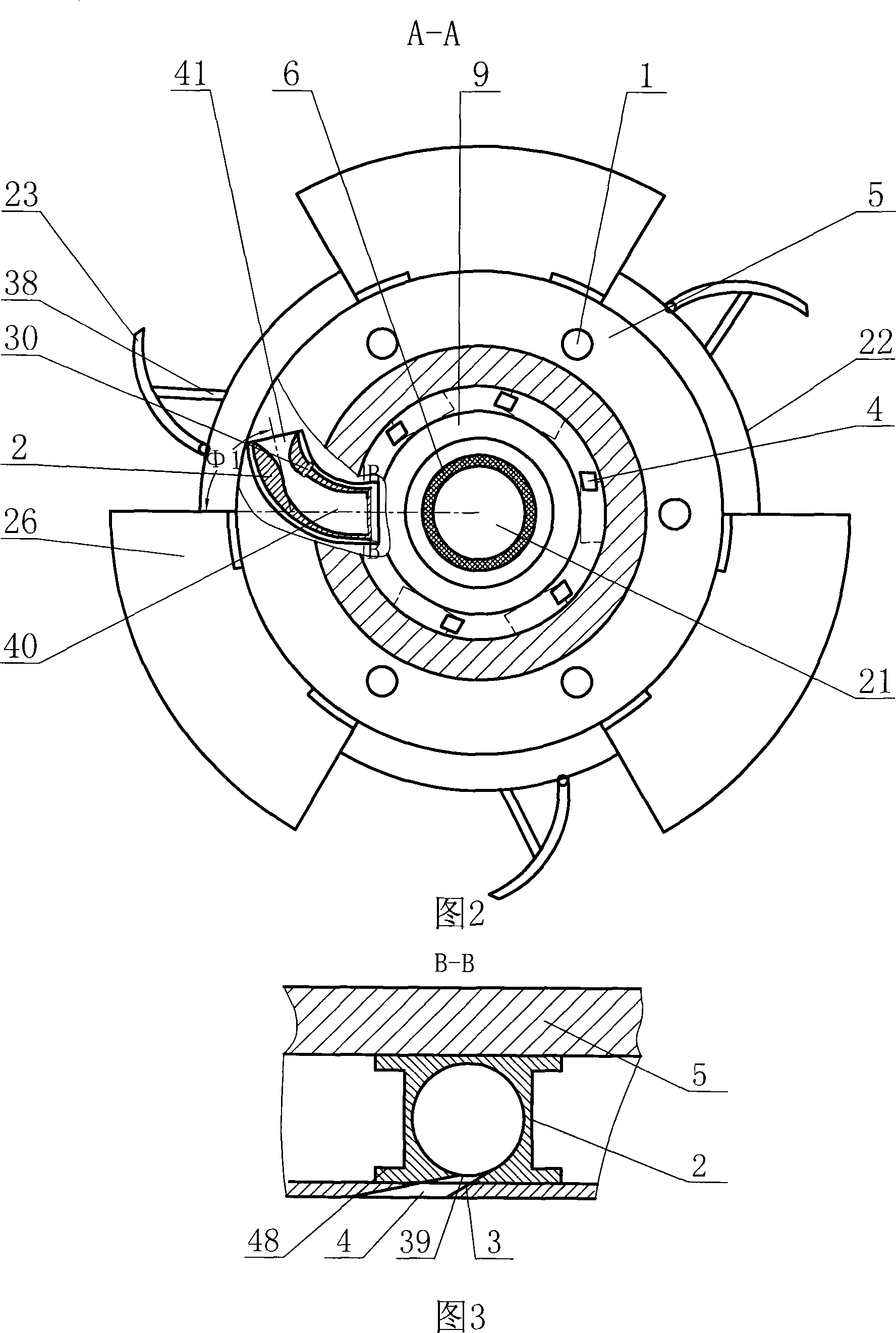

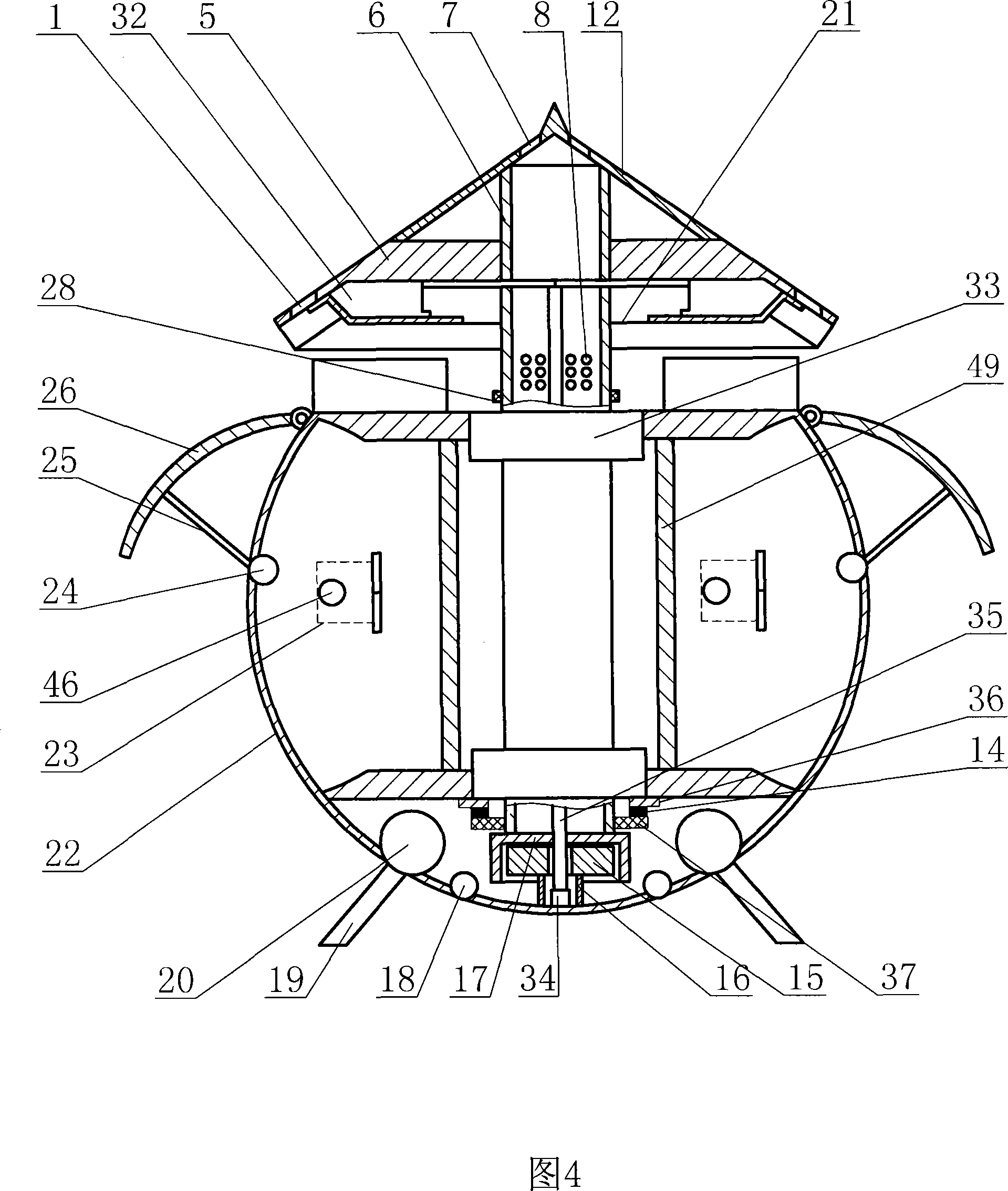

[0008] The main structure of the present invention is: flying saucer, comprising cabin body 22, control system, electrical system, cabin facilities, fuel system, starting system and ignition system, cabin body motion direction regulating device and cabin body rotation stability adjustment are installed on the cabin body 22 Device, fuel tank 27 is installed on the cabin body 22, and fuel pipe 29 is set on the fuel tank 27, and flywheel jet engine is installed on the cabin body 22, and flywheel jet engine comprises flywheel shaft 6, flywheel 5 and jet device, flywheel shaft 6 and cabin body 22 Connection, the flywheel 5 is installed on the flywheel shaft 6, and multiple air injection devices are installed on the periphery of the flywheel 5. The angle between the air injection direction of the air injection device and the radius of the flywheel 5 is Φ1. After research, the optimal value of Φ1 ranges between 55.62°-68.76° , can help to overcome part of the centrifugal force to offs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com