Pedrail running gear without thrust wheel

A walking device and crawler-type technology, which is applied to tracked vehicles, transportation and packaging, motor vehicles, etc., can solve problems such as impact, track shoe breakage, and large machine vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

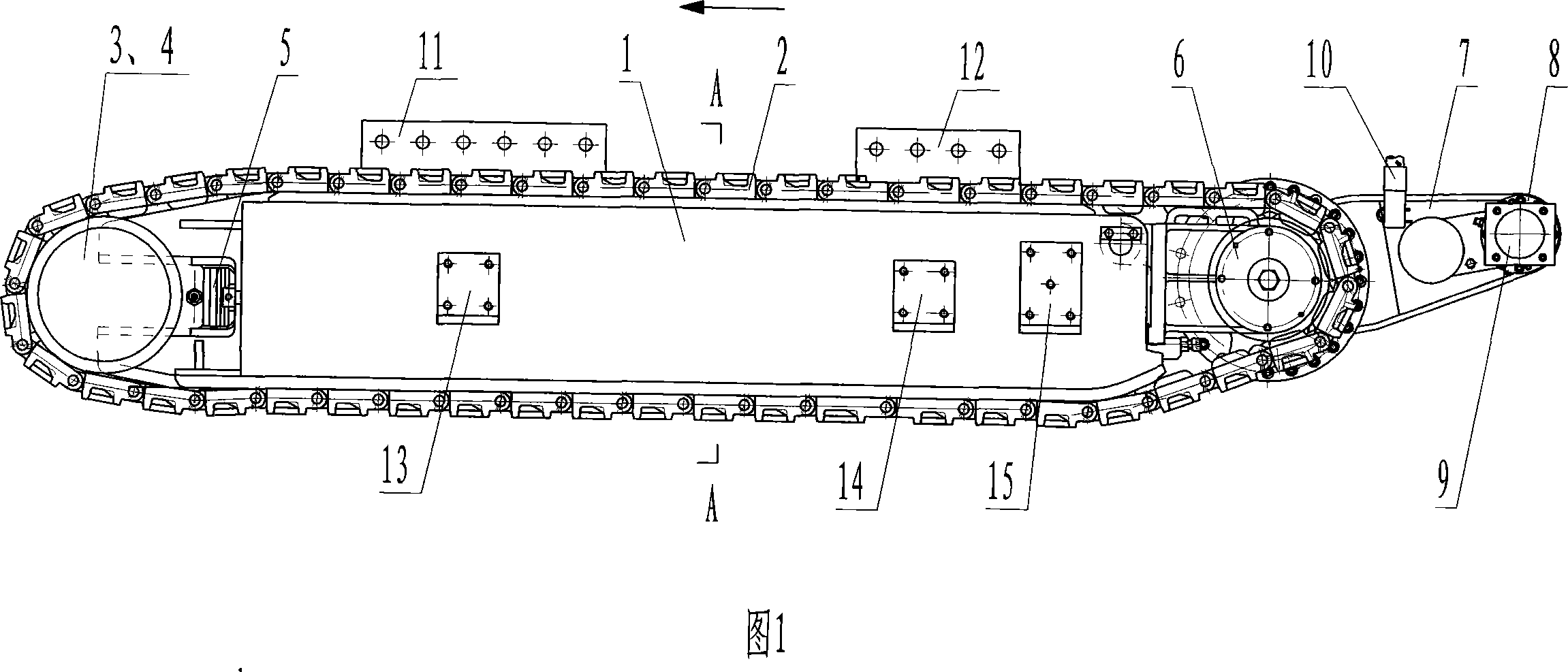

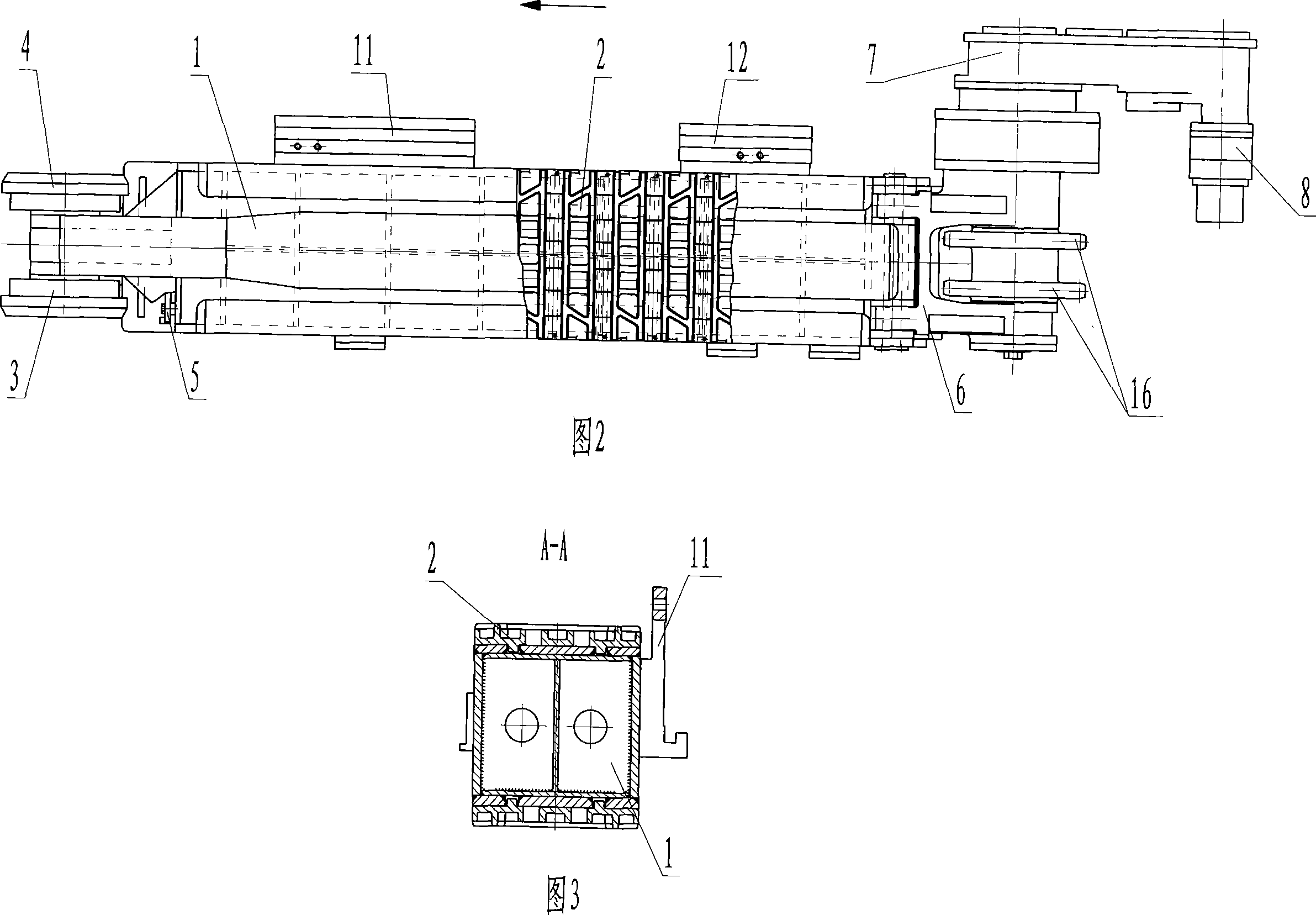

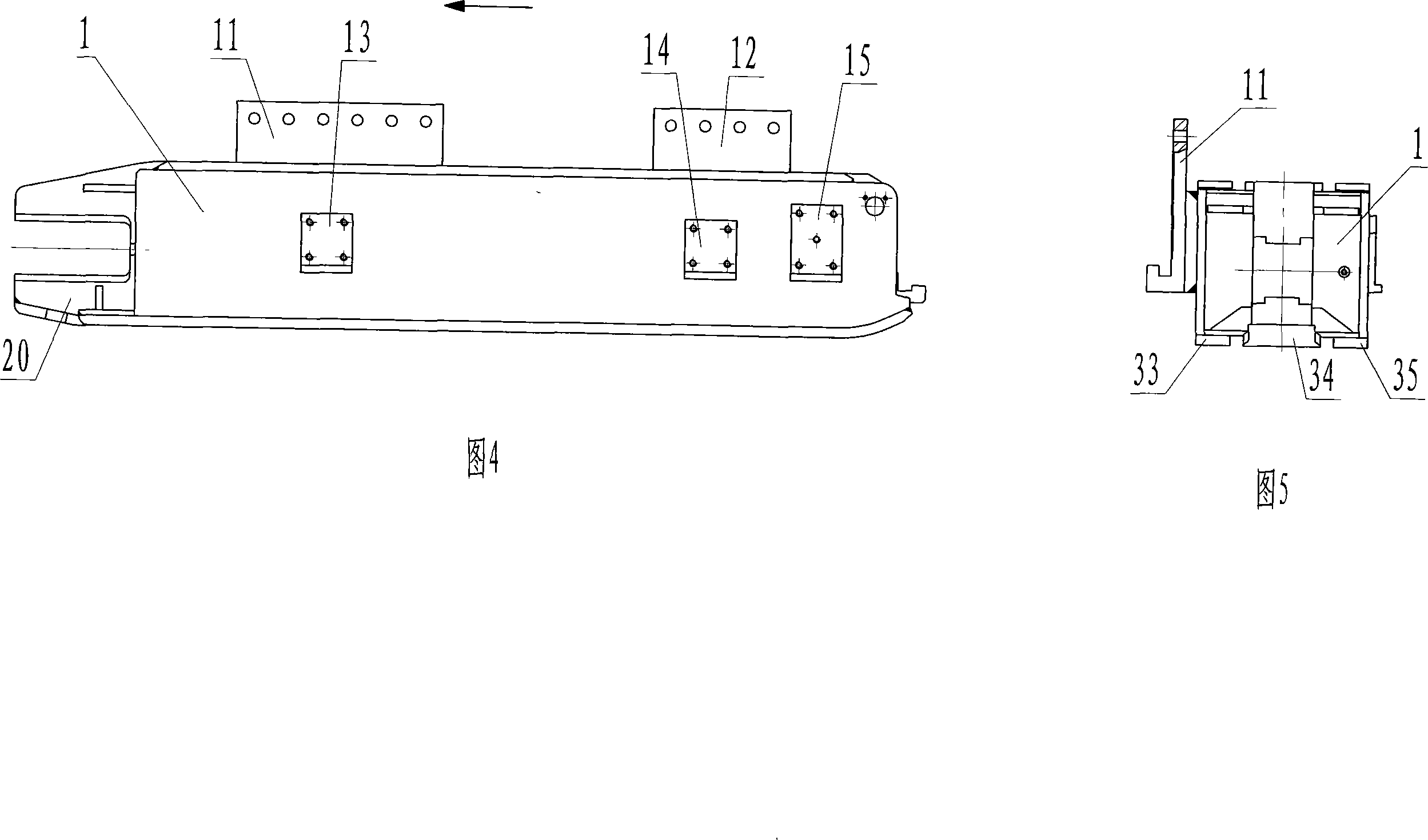

[0031] The present invention will be further described below in conjunction with accompanying drawing:

[0032] Shown in Fig. 1, 2, 3, it is the overall structure diagram, and it is main body with crawler frame 1, guide wheel 3, 4 is housed at the front, the tension oil cylinder 53 of tension mechanism 5 can adjust its tightness, in The rear portion is driven by the drive mechanism 6 to drive the double-toothed sprocket 16 to make the traveling device move forward, retreat or turn.

[0033] The driving mechanism 6 is connected to the brake 8 by the hydraulic motor 9, and drives the gear reduction mechanism in the reducer 7. After the three-stage shaft gear deceleration, and then the secondary row gear deceleration, the driving mechanism 6 finally drives the whole machine to run and walk. The speed ratio is 243.16:1, and the speed of the traveling mechanism should meet the needs of the coal mine underground, and should not be too fast, and it is better to be stable and reliable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com