Needle jack having needle selecting function

A technology of needle jacks and needle selection, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of complex machine head structure, large body size, and large needle plate size, so as to reduce consumables and size The effect of reducing and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The utility model will be further described below in conjunction with accompanying drawings and embodiments.

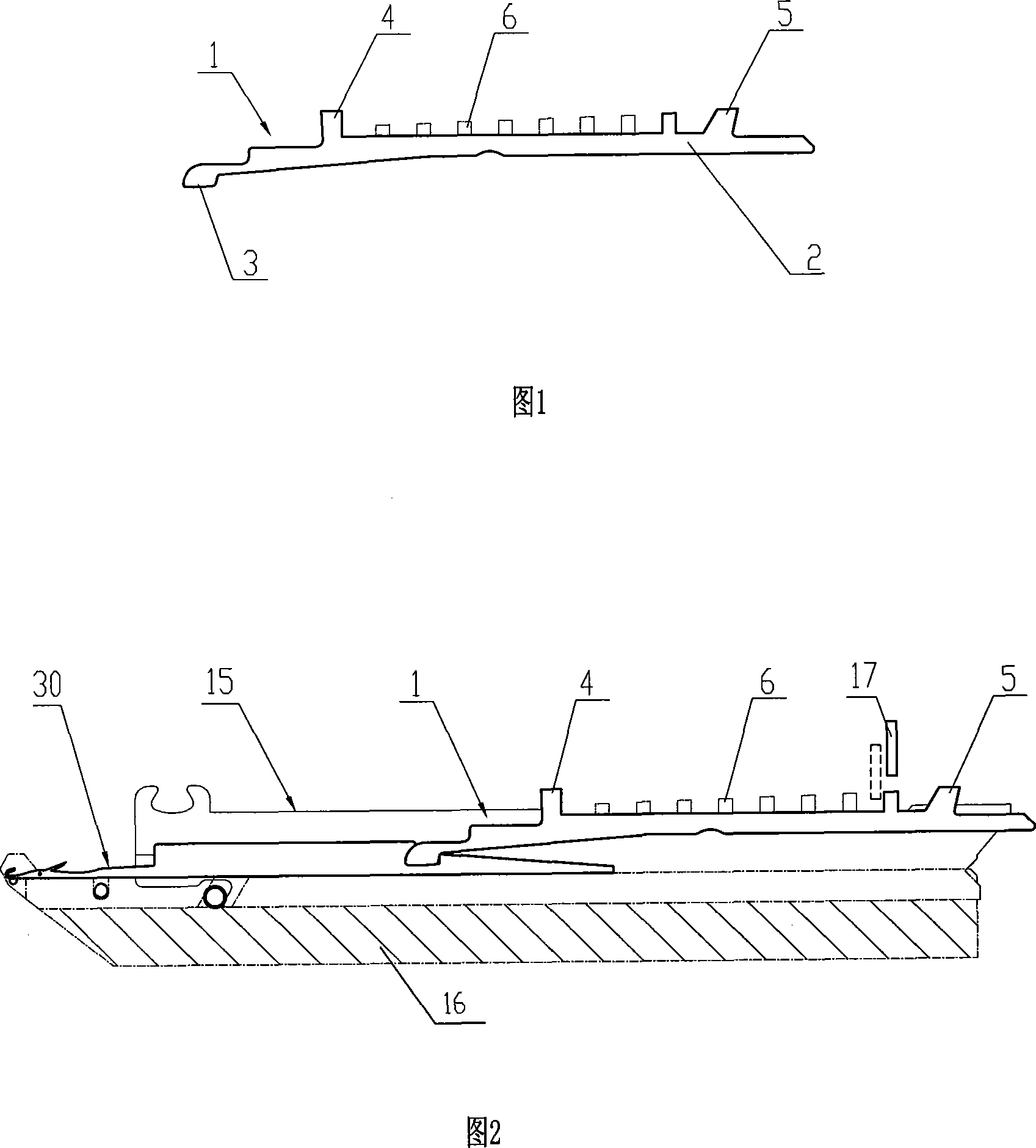

[0016] Referring to Fig. 1, the needle jack with needle selection function of the present invention is a planar sheet structure like the existing needle jack. It has a planar sheet-like base 2 , and an embedding portion 3 extends forward from the front end of the base 1 for connecting with knitting needles 30 . On the upper side of the base 2 , selector teeth 6 , front butts 4 and rear butts 5 extend upward.

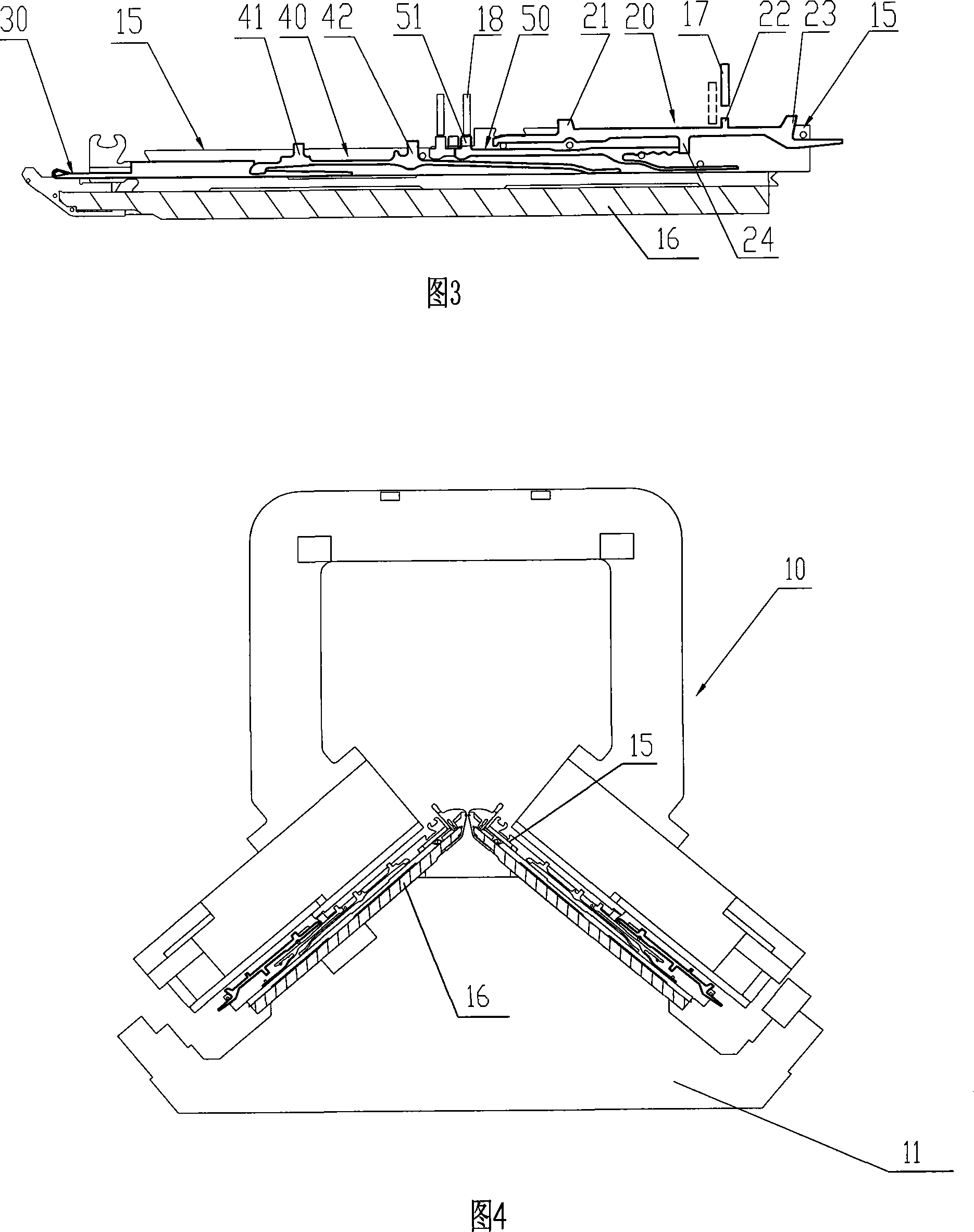

[0017] Referring to Fig. 2, the needle jack 1 with the structure of the present invention is placed in a needle groove 15 on the needle plate, and the embedding part 3 at its front end is inlaid with the knitting needle 30, and only the knitting needle 30 and the needle jack are in the needle groove 15. 1. The length of the needle groove 15 is greatly shortened, so that the corresponding size of the needle plate and the needle bed can be greatly reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com