Electromagnetic displacement control valve in clutchless type variable displacement compressor

A technology with no clutch and electromagnetic capacity, which is applied in liquid displacement machinery, pump control, machine/engine, etc. It can solve the problems of reducing refrigerant and increasing the inclination angle of the swash plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

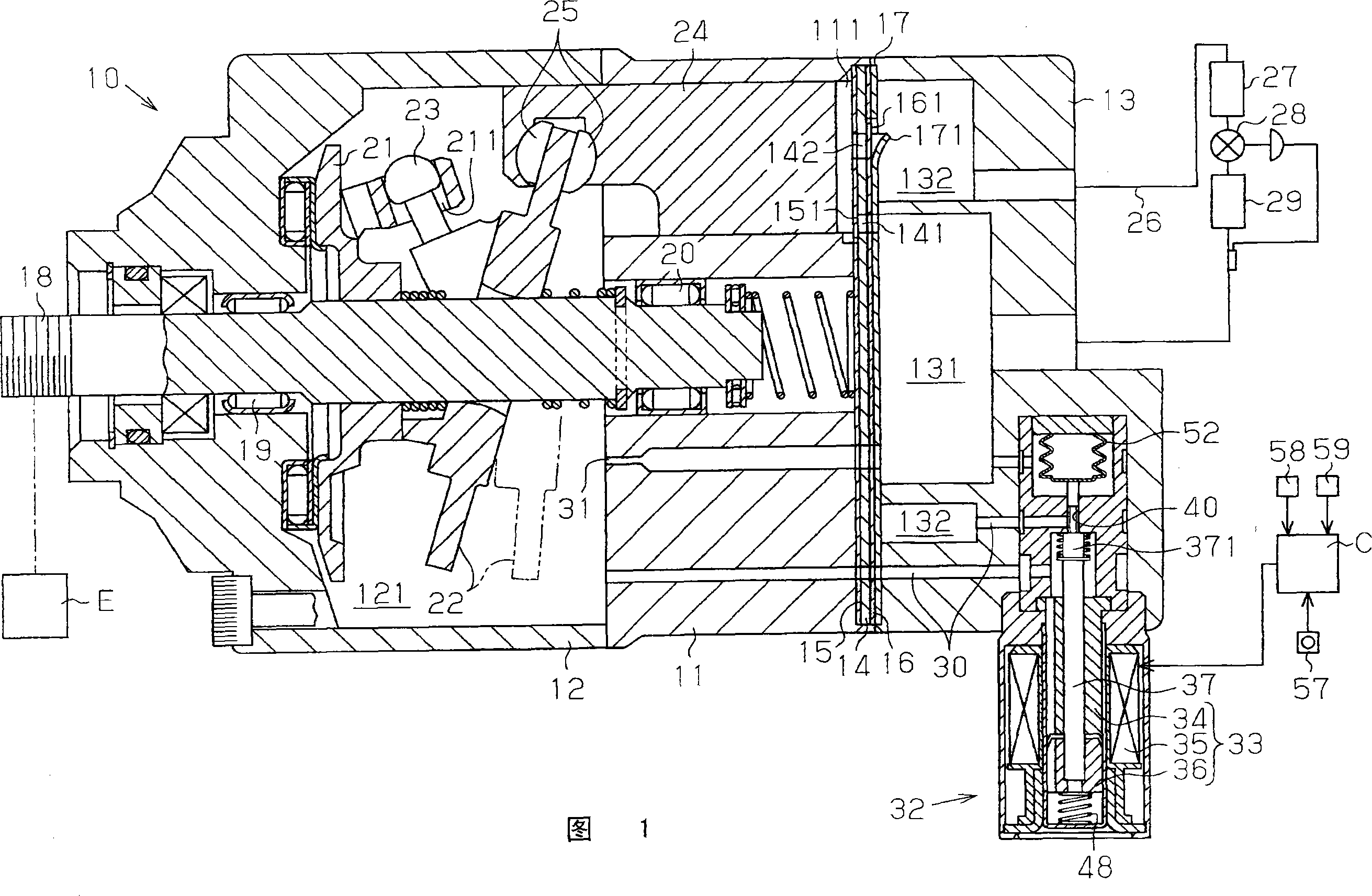

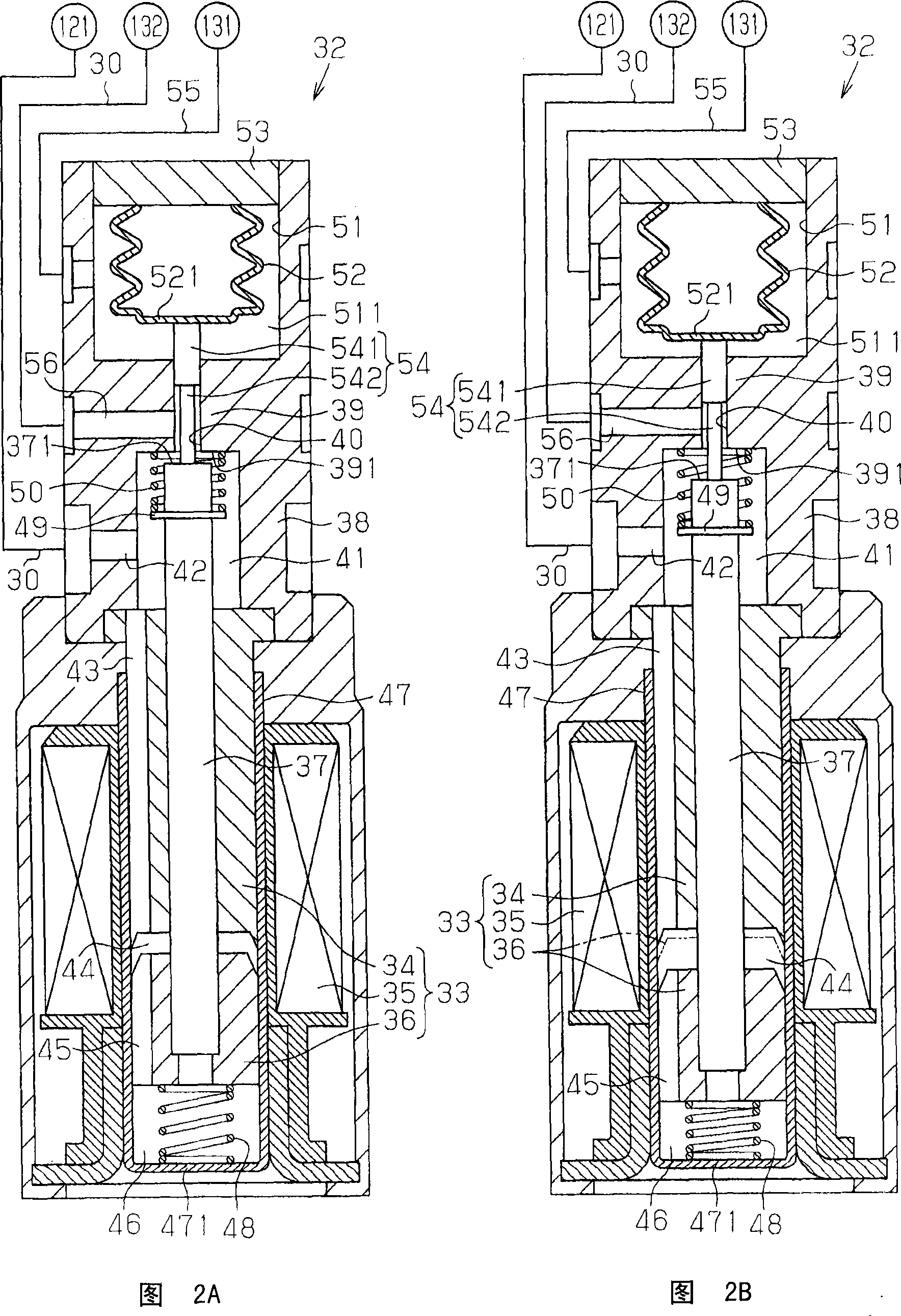

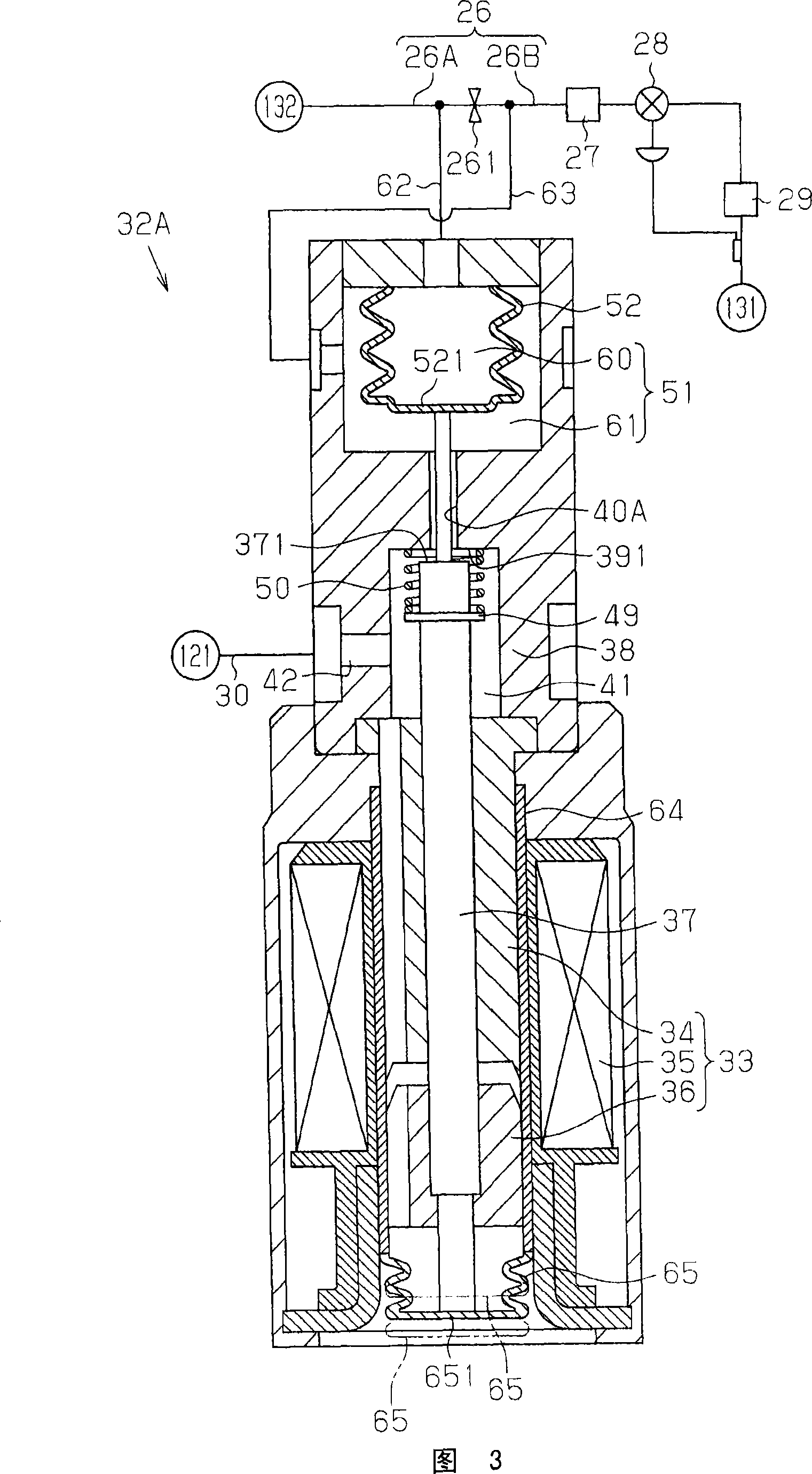

[0013] A first embodiment of the present invention will be described with reference to FIGS. 1 to 2B.

[0014] As shown in FIG. 1 , the casing of the variable capacity compressor 10 includes a cylinder block 11 , a front casing member 12 , and a rear casing member 13 . The front housing member 12 is mounted to the front end of the cylinder body 11, the rear housing member 13 is mounted to the rear end of the cylinder body 11, and the valve plate 14, valve disc plates 15, 16, and retaining plate 17 are installed therebetween. The cylinder block 11 , the front casing member 12 and the rear casing member 13 are constituted in the casing of the compressor 10 . The compressor 10 constitutes a part of an air conditioner fitted to, for example, a vehicle.

[0015] The front housing member 12 and the cylinder block 11 define a control pressure chamber 121 . The front housing member 12 and cylinder block 11 rotatably support a rotary shaft 18 via radial bearings 19 , 20 . The rotary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com