Apparatus and method for detecting filters lustration degree

A detection equipment and detection method technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, measuring devices, etc., can solve the problems of decreased product yield, unavailability of products, waste of time, etc., to avoid wasting time and convenient. and accurate detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

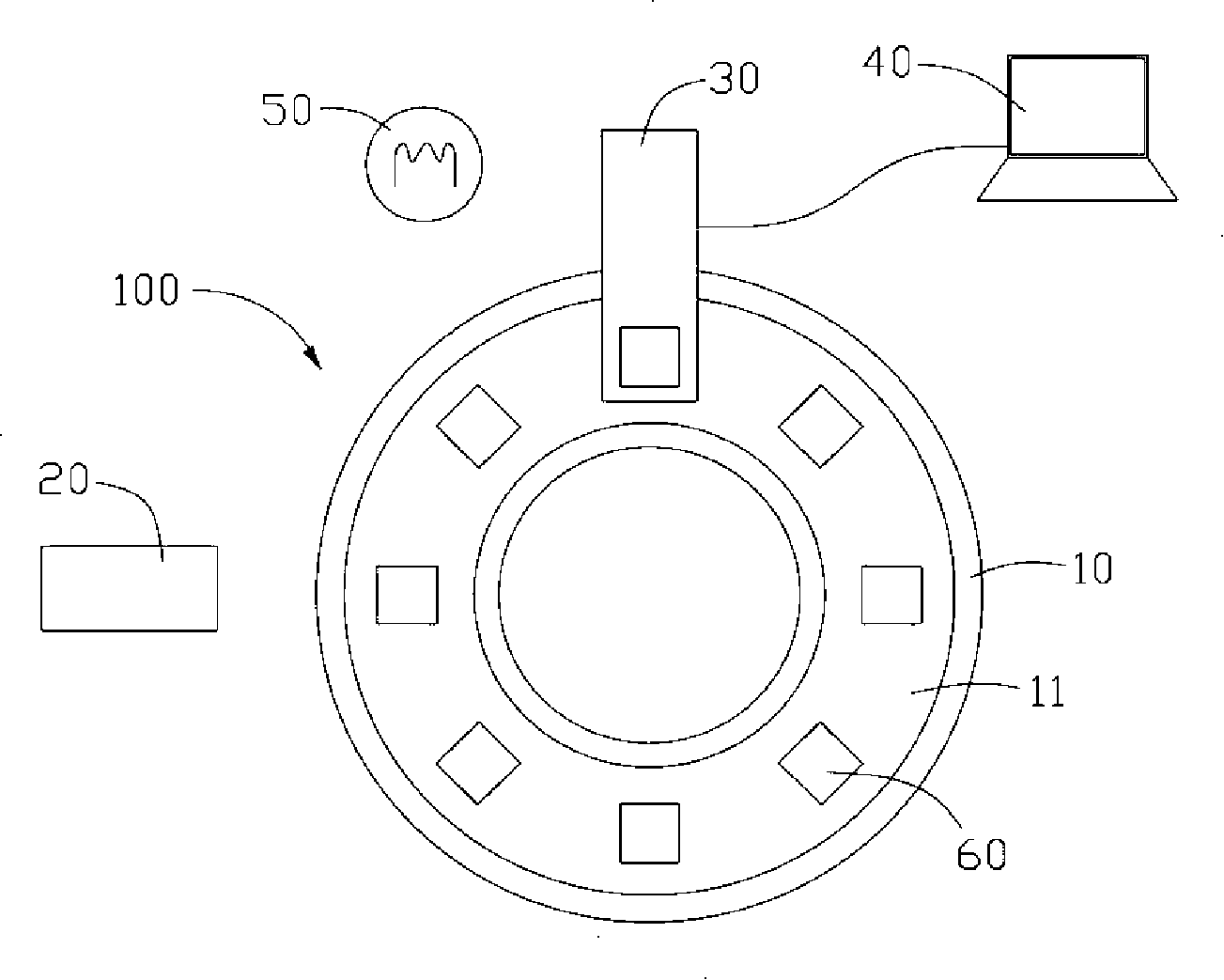

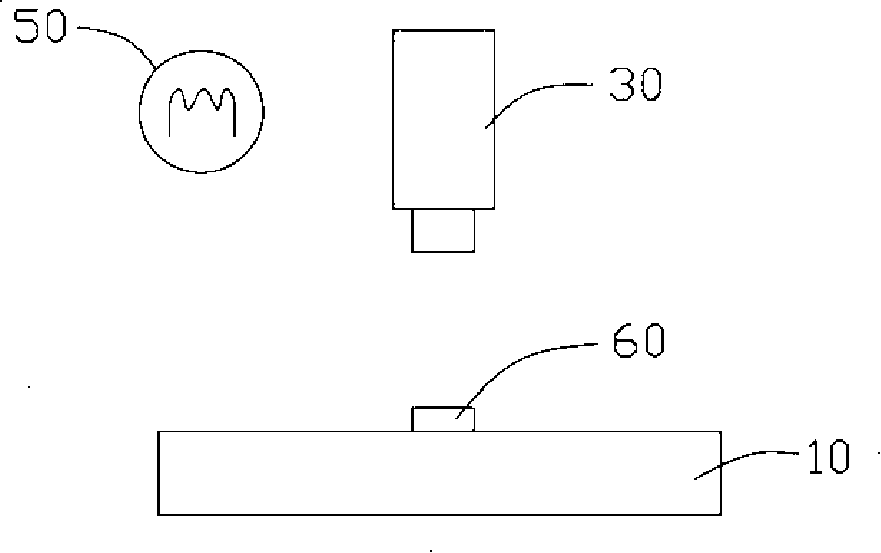

[0012] see figure 1 , the embodiment of the present invention provides a detection device 100 for the cleanliness of an optical filter. The detection equipment includes a base 10 , a dust removal device 20 , an image acquisition device 30 , and an image processing and analysis system 40 .

[0013] The base 10 further includes a conveyor belt 11 . The conveyor belt 11 moves in one direction at a certain speed. In this embodiment, the conveyor belt 11 moves clockwise. The optical filter 60 to be tested is put in from the right side of the base 10 , conveyed by the conveyor belt 11 , and passes through the corresponding positions of the dust removal device 20 and the image acquisition device 30 in turn, so that the entire detection process can be realized.

[0014] The dust removal device 20 is an ion air gun, and the air outlet of the ion...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap