Ball bearing switch and its making method

A technology of ball switches and balls, applied in electric switches, electrical components, circuits, etc., can solve the problems of poor movement stability, inconsistent movement, time-consuming assembly, etc., and achieve the effect of good movement stability and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

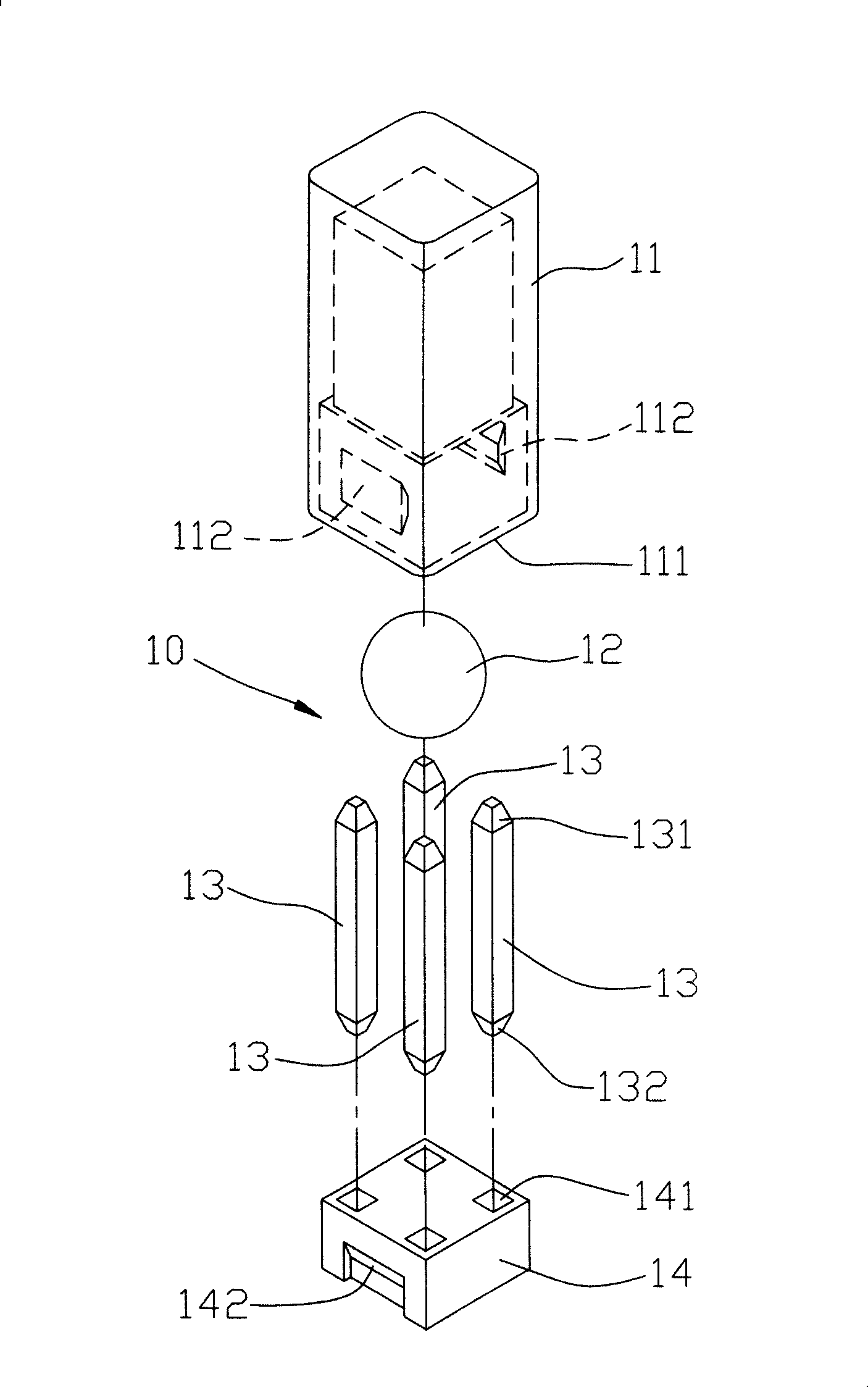

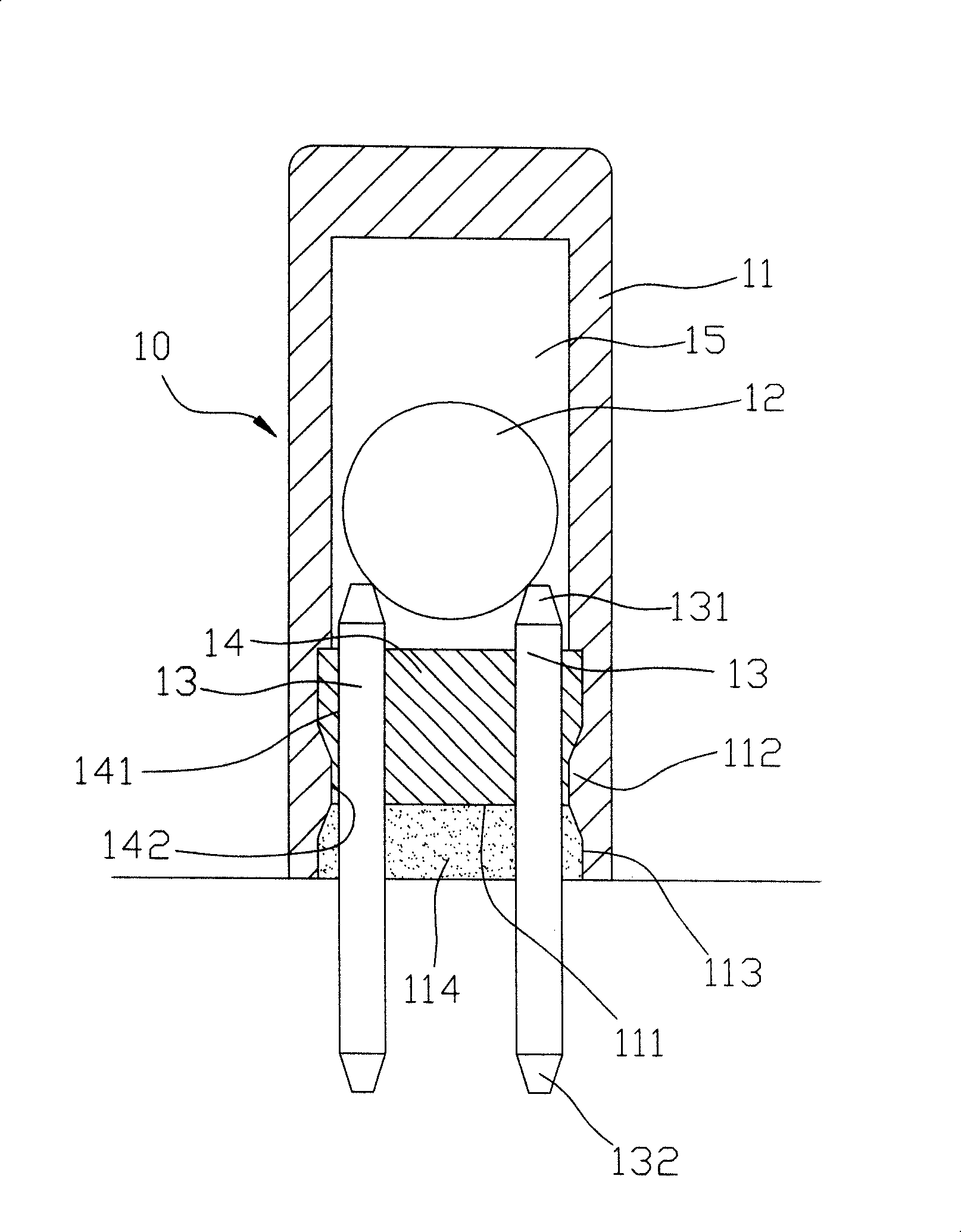

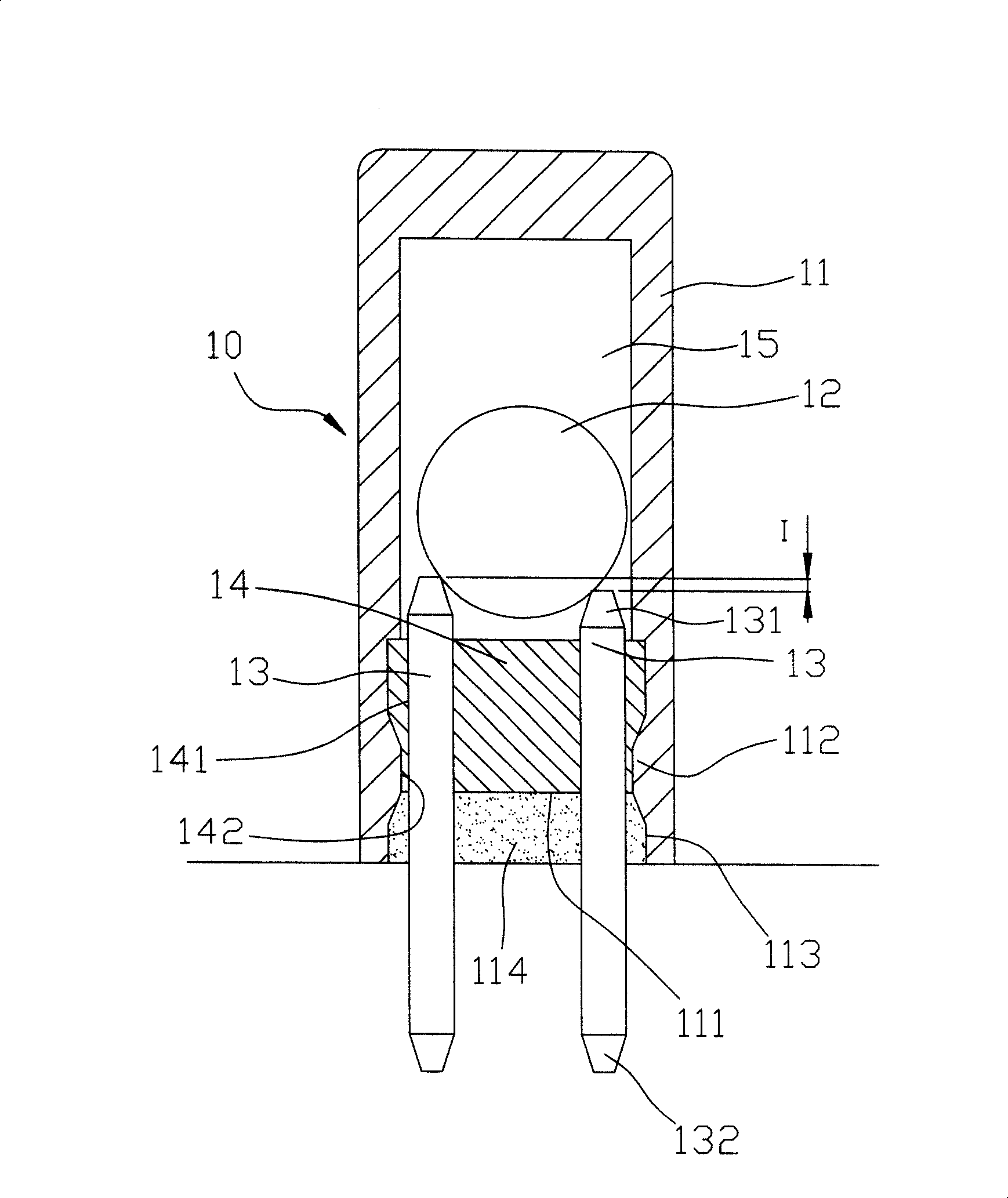

[0037] The ball switch and its manufacturing method according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

[0038] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

[0039] Such as Figure 4 , shown in FIG. 5 , the first preferred embodiment of the ball switch 2 of the present invention includes a first insulating shell 3 , a second insulating shell 4 , an insulating intermediate body 5 , two metal sheets 6 and a ball 7 .

[0040] As shown in Figure 5, Image 6 , Figure 7 As shown, the first insulating shell 3 is made of plastic molding, and is basically a square shape, with a first chamber 31 around an axis II and one end open, and two spaced apart from each other along the axis II A concave portion 32 and two convex portions 33 .

[0041] The second insulating shell 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com