Constant temperature conveyer of polishing solution

A conveying device and polishing liquid technology, which is applied in the direction of grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems affecting the surface quality of workpiece processing, workpiece fragments, insufficient supply of polishing liquid, etc., and achieve constant temperature control of polishing liquid The effect of temperature, lifting mass, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

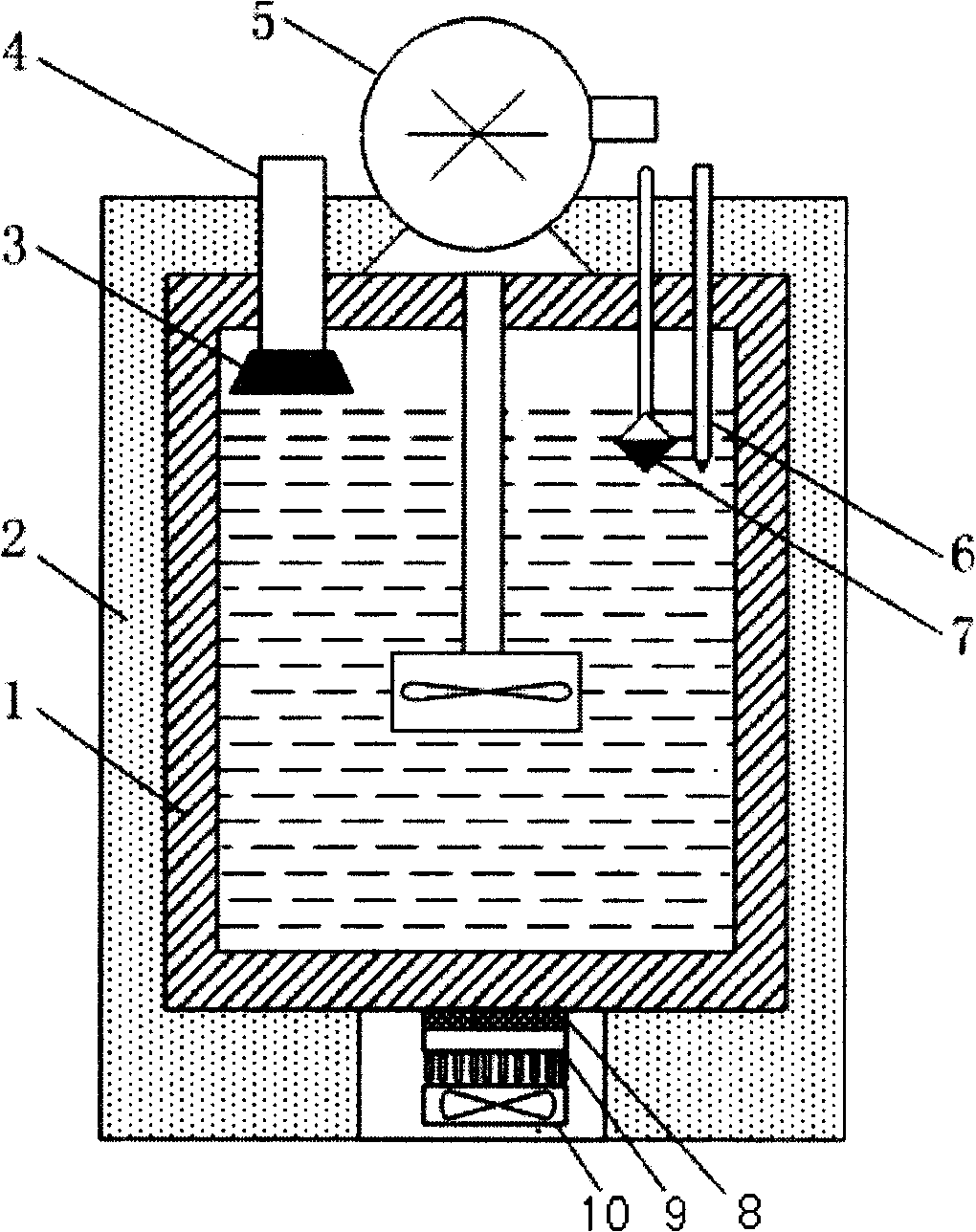

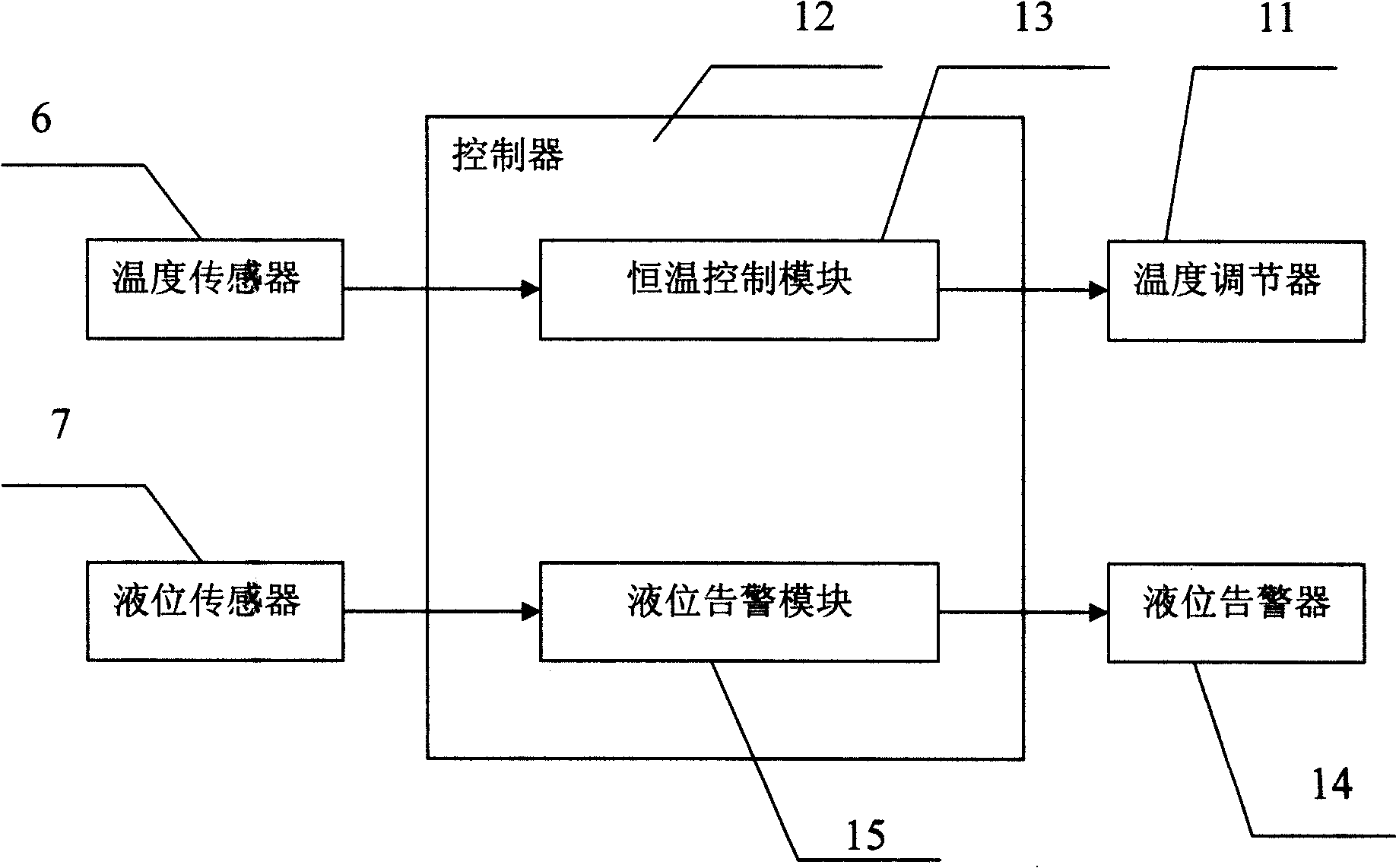

[0022] refer to figure 1 , figure 2 , a constant temperature delivery device for polishing liquid, comprising a barrel body 1 for storing polishing liquid, a heat insulating layer 2 is provided outside the barrel body, and a polishing liquid conveying device communicating with the polishing processing area is provided on the barrel body 1 Pump 5, return pipe 4, described polishing fluid constant temperature conveying device also comprises temperature regulator 11, temperature sensor 6 and controller 12, and described temperature regulator 11 is installed on barrel body 1 outer wall, and described temperature sensor 6 Installed in the barrel body 1, the controller 12 is used to control the temperature regulator to heat when the temperature measured by the temperature sensor is lower than the set value, and to control the temperature when the temperature measured by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com