Protection fence for rolling wheel rubber belt

A tape and roller technology, applied in bridge guardrails and highways, can solve the problems that the guardrails have no guiding effect and the driver is difficult to control and return to the right path, so as to reduce passenger casualties, reduce vehicle damage rate, and save steel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

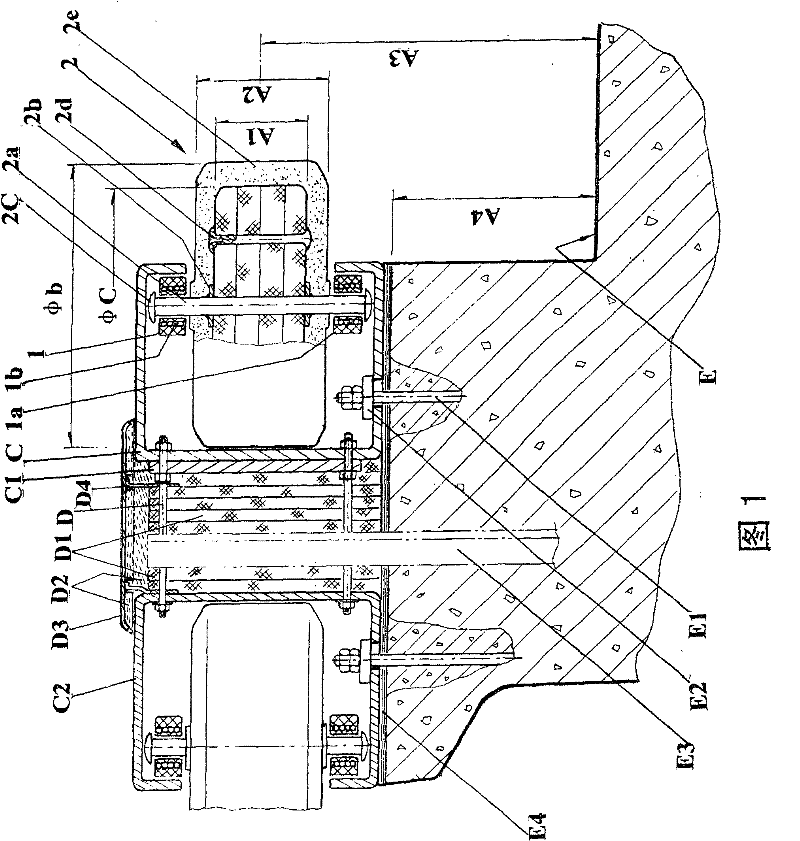

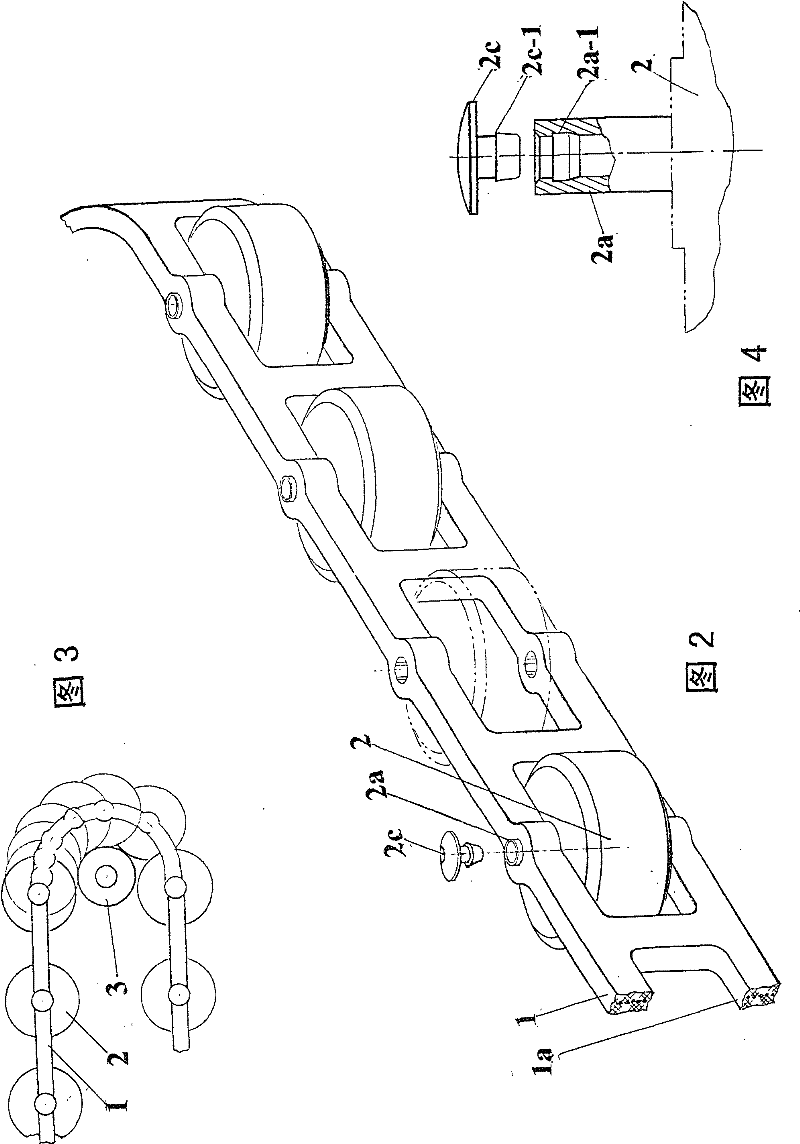

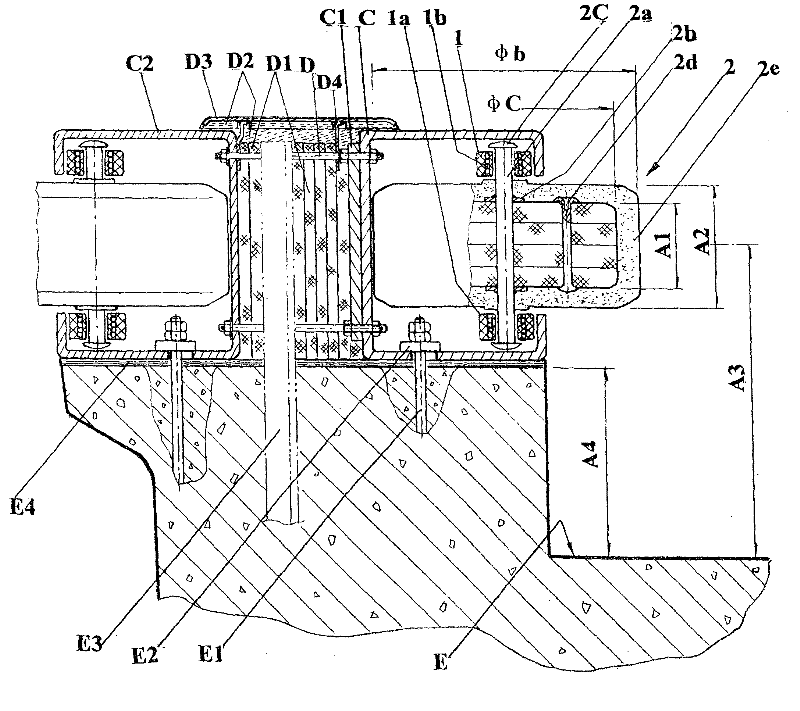

[0011] see figure 1 ~Fig. 4, the present invention is made up of roller and adhesive tape; figure 2 It can be seen that the shape of the tape is like a ladder, its upper side 1 and lower side 1a are like the two legs of the ladder, and the connecting part between the upper side 1 and the lower side 1a is like a ladder rack, and the airspace between the rack and the rack is equipped with a Roller 2, roller axle 2a penetrates in the hole of top 1 and bottom 1a with moving fit, and top 1 and bottom 1a bend easily when not tensioned, can pack into roller.

[0012] Fig. 4 is a partial enlargement of the roller shaft 2a. There is an undercut 2a-1 inside the end of the (steel pipe) roller shaft, which is fastened with the inverted cone 2c-1 of the (spherical) bulkhead 2c with an interference fit. The upper and lower sides of the roller shaft 2a Each has a dull head 2c.

[0013] Fig. 3 is the guiding schematic top view of guide wheel 3, at the turning position of endless belt 1, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com