Four-drive traveller of development machine

A walking mechanism and four-drive technology, which is applied in the field of mining machinery, can solve the problems of reducing the climbing ability of the roadheader, the narrowing of the ability range, and the stuffiness of the walking power source, so as to shorten the braking response time, improve the braking ability, and improve the The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

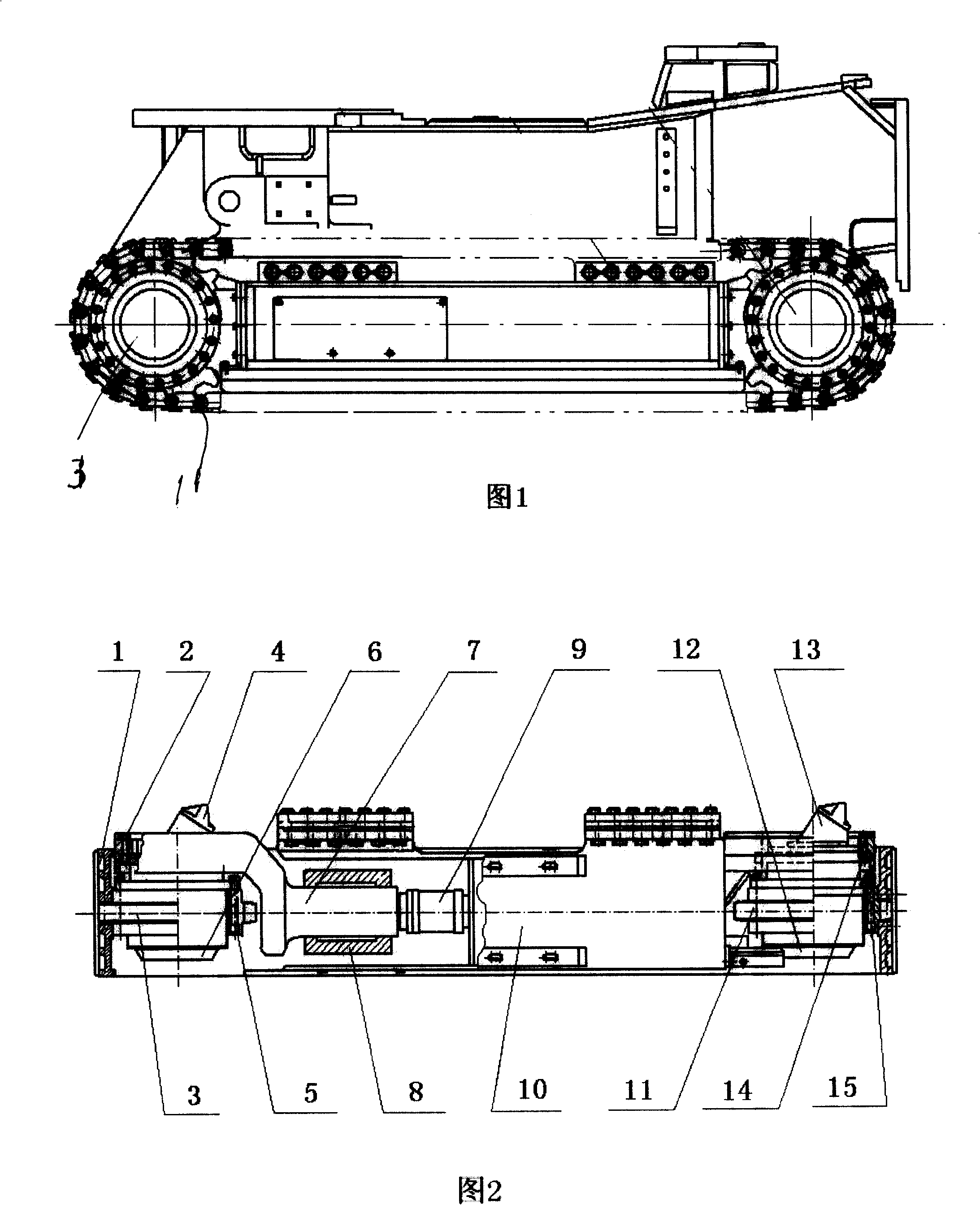

[0016] As shown in the front view of the four-drive traveling mechanism of the roadheader of the present invention in Figure 1 and the top view of the four-drive travel mechanism of the roadheader in Figure 2, the four-drive travel mechanism of the roadheader of the present invention is composed of two groups of crawler belt systems, as shown in Figure 2 The track system is composed of the following components: track 1, front reducer bolt 2, front (guide) drive wheel 3, front power source 4, front (guide) drive wheel bolt 5, front reducer 6, front drive frame 7, Front drive support 8, tensioning device 9, walking support 10, rear drive wheel 11, rear reducer 12, rear power source 13, rear reducer bolt 14, rear drive wheel bolt 15, wherein: rear power source 13 and rear The speed reducer 12 is fixedly connected, and the rear driving wheel 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com