Longitudinally wound two-stroke diesel motor and method for operating the same

A diesel engine, stroke technology, applied in electrical control, mechanical equipment, engine control, etc., can solve problems such as high operating costs, increased combustion temperature, and shortened service intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

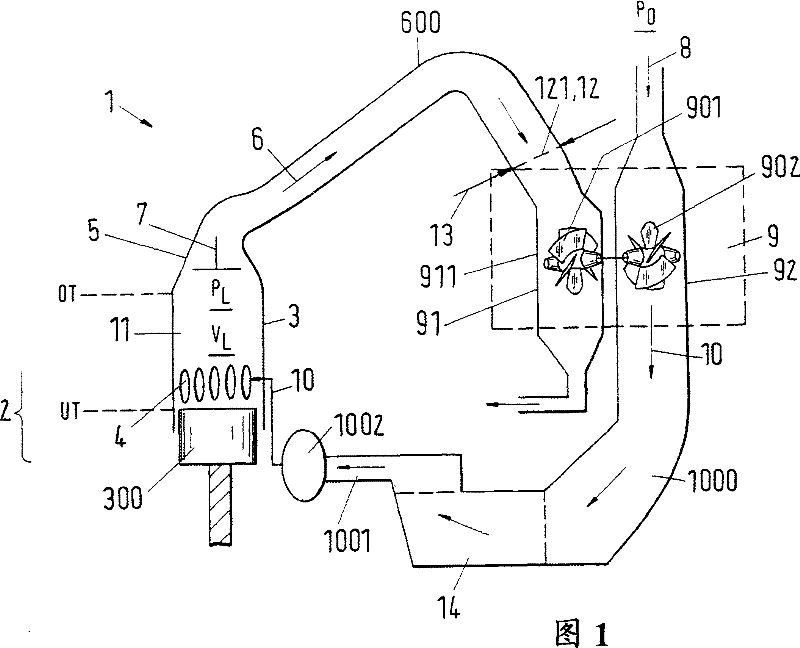

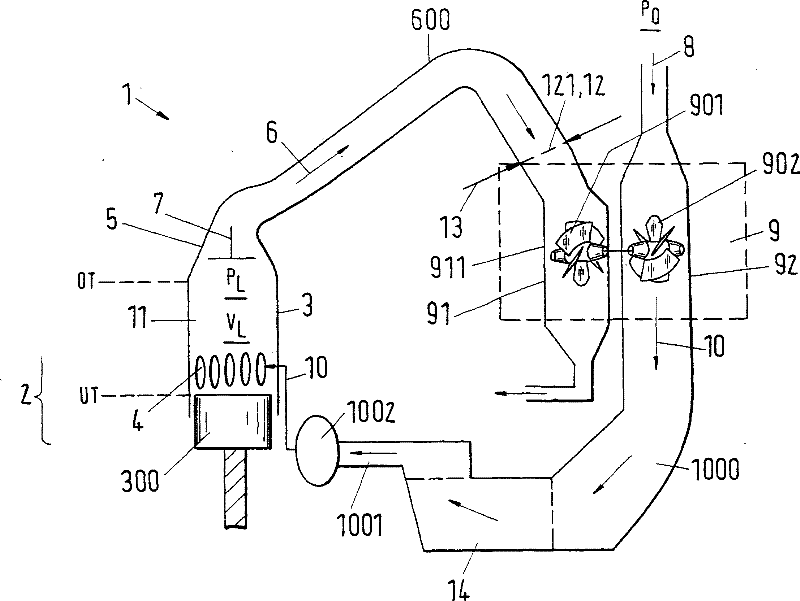

[0041] To explain the cooperation of the different components, figure 1 The principle structure of an exhaust gas turbocharger system of a large diesel engine according to the invention is shown schematically, which is designed as a two-stroke large diesel engine with longitudinal scavenging, and which is designated with reference numeral 1 throughout the following text.

[0042] A large diesel engine 1 generally comprises, in a manner known per se, a plurality of cylinders 3 with exhaust valves 7 arranged in a cylinder head 5, and wherein a piston 300 is arranged between bottom dead center UT and top dead center OT along the running surface Move back and forth in cylinder 3. The cylinder walls of the cylinder 3 with the cylinder head 5 and the piston 300 delimit the combustion space of the cylinder 3 in a known manner. A plurality of scavenging air openings 4 designed as scavenging air slots 4 are arranged in the intake region 2 of the cylinder 3 . The scavenging slot 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com