Substrate support assembly

A technology for components and supporting substrates, which can be used in electrical components, semiconductor/solid-state device manufacturing, crystal growth, etc., to solve the problems of burn-in connector glow discharge or micro-arcing, damage, and increase the cost of unit substrate preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

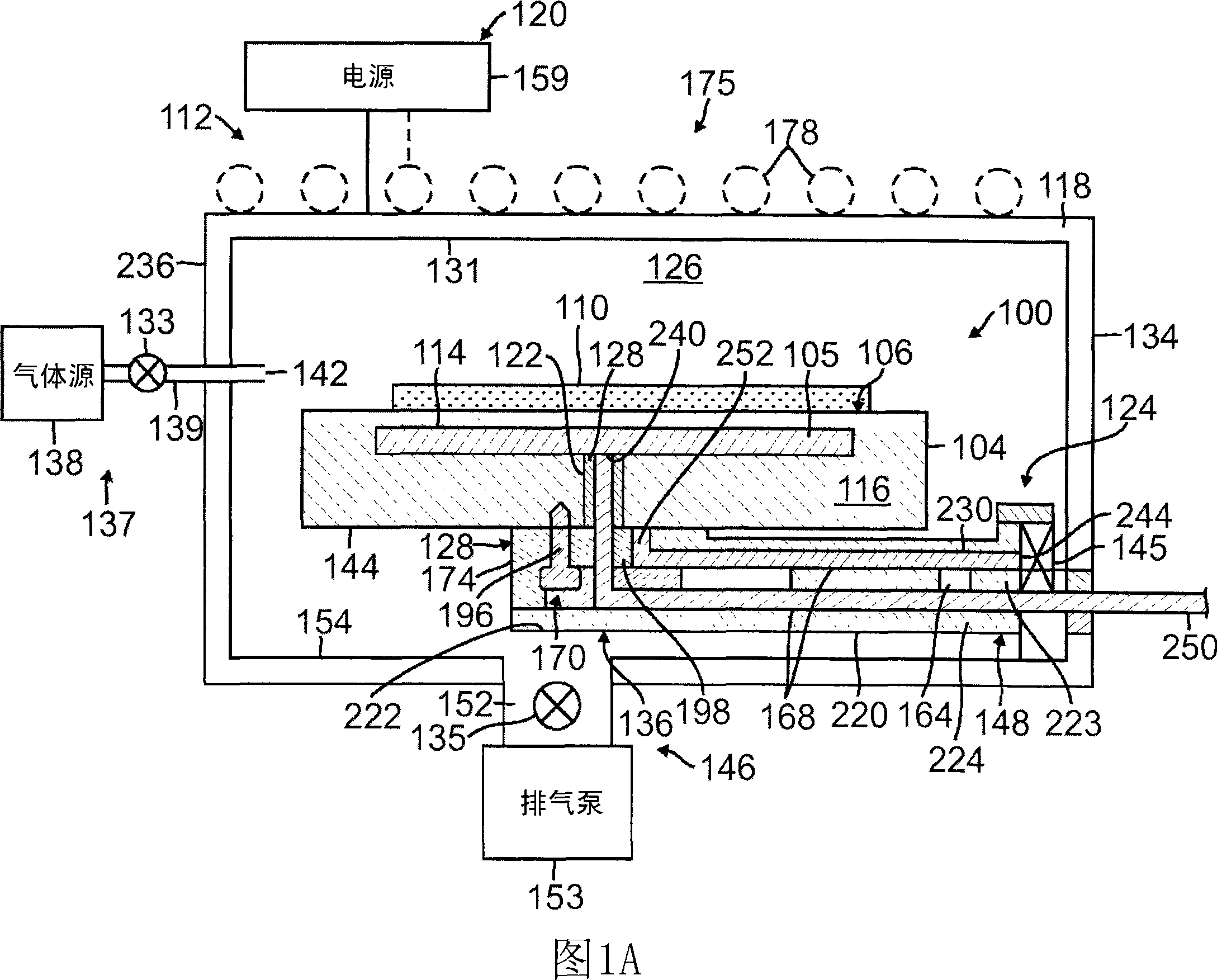

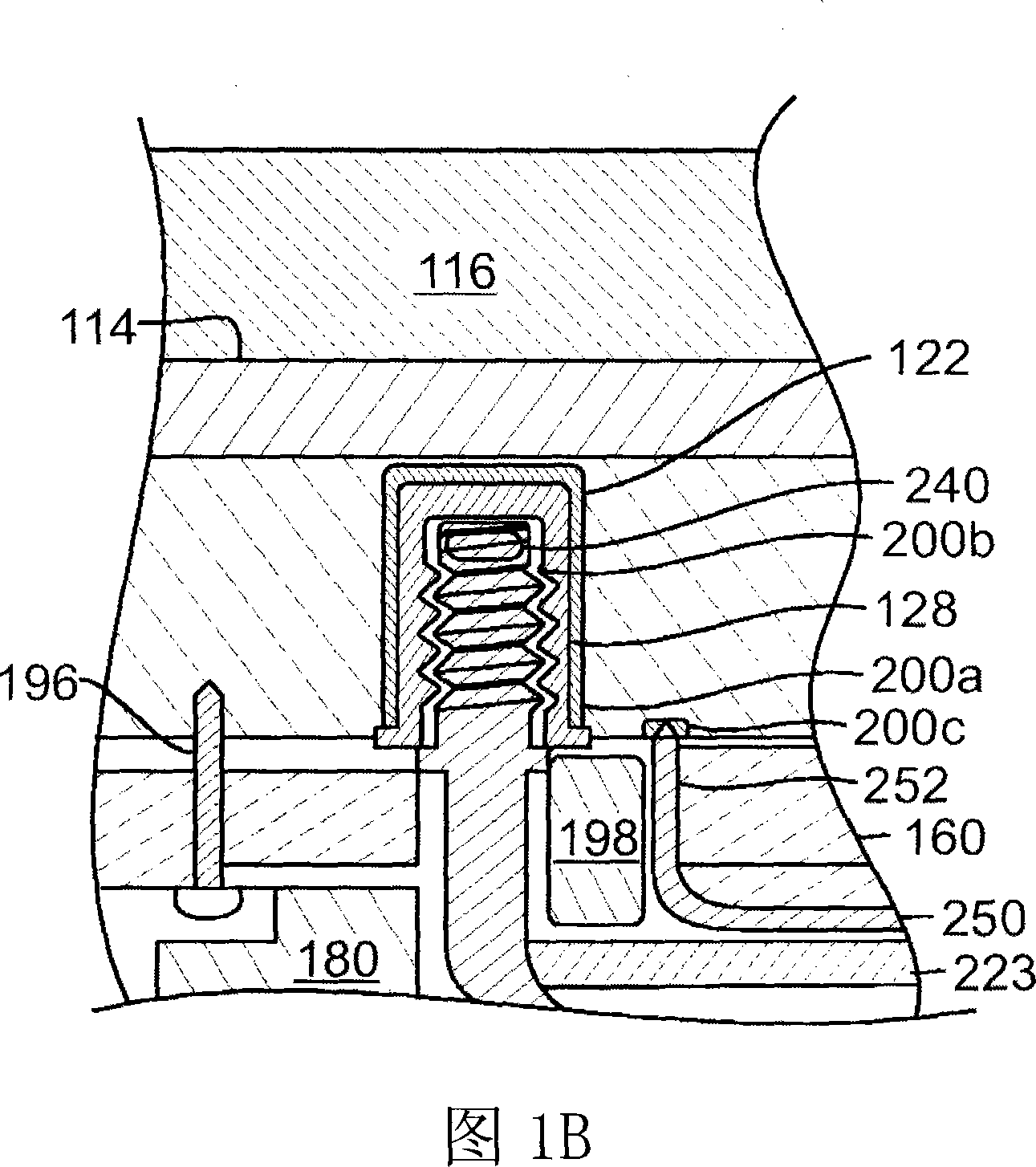

[0017] As shown in FIG. 1A , the substrate support assembly 100 includes a support block 104 having a substrate receiving surface 106 for supporting a substrate 110 in a processing chamber 112 . In the form shown, the standoff block 104 includes a dielectric block 116 made of, for example, aluminum nitride, aluminum oxide, or silicon oxide. Dielectric block 116 may be a monolithic or unitary structure of dielectric material (as shown), or may be made from multiple stacked plates of dielectric material. While one form of substrate support assembly 100 is shown here, it should be understood that other forms are within the scope of the present invention as will be apparent to those skilled in the art. For example, support block 104 may also be a metal block constructed of aluminum or stainless steel with a corrosion resistant coating such as anodized aluminum disposed on substrate receiving surface 106 .

[0018] The support block 104 includes an electrode 114 adapted to be part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com