Control of an electrical machine

A technology of switched reluctance motor and operating mode, which is applied in control system, AC motor control, single motor speed/torque control, etc. It can solve the problem of not considering progress and achieve the effect of reducing switching frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

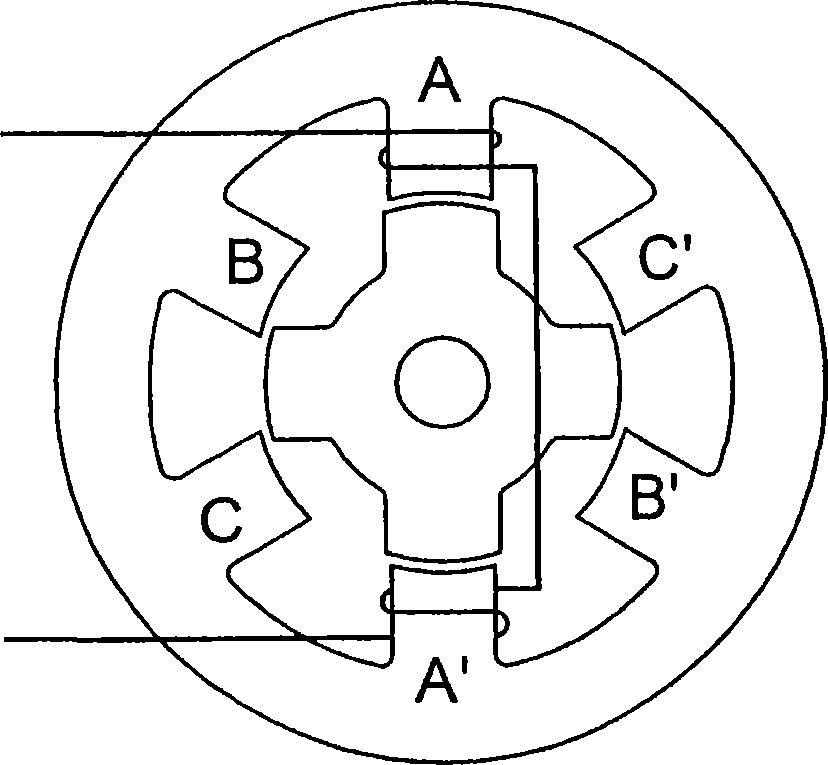

[0052] Fig. 6 shows the rectangular waveform of the sensor output of Fig. 4(b) superimposed with the triangular phase flux waveform. Pick an arbitrary point as the operating point of the system for interpreting the sensor waveform (e.g., typically L min ) on the rising edge of the switch is turned on and the switch is turned off a quarter of a cycle later. The purpose here is to explain. The operating point at which the switch is turned on to start energization and drives the flux up and the switch is turned off to drive the flux down varies. The phases of the motor are energized in a predetermined sequence ABC.

[0053] Figure 7 shows one embodiment graphically. The motor still runs at the same speed as in Figure 6. The speed at which the rotor poles pass the stator poles is thus the same. Therefore, the period of the sensor waveform is the same. However, each phase is now energized at a lower rate, in this case half the original rate. When the rotor poles reach the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com