Electric oil injector

An electronic fuel injection and nozzle technology, which is applied in the direction of fuel injection devices, charging systems, engine components, etc., can solve the problems of poor injection randomness and stability, poor hot start and stability, and large influence of fuel vapor, so as to improve injection The effect of stability, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

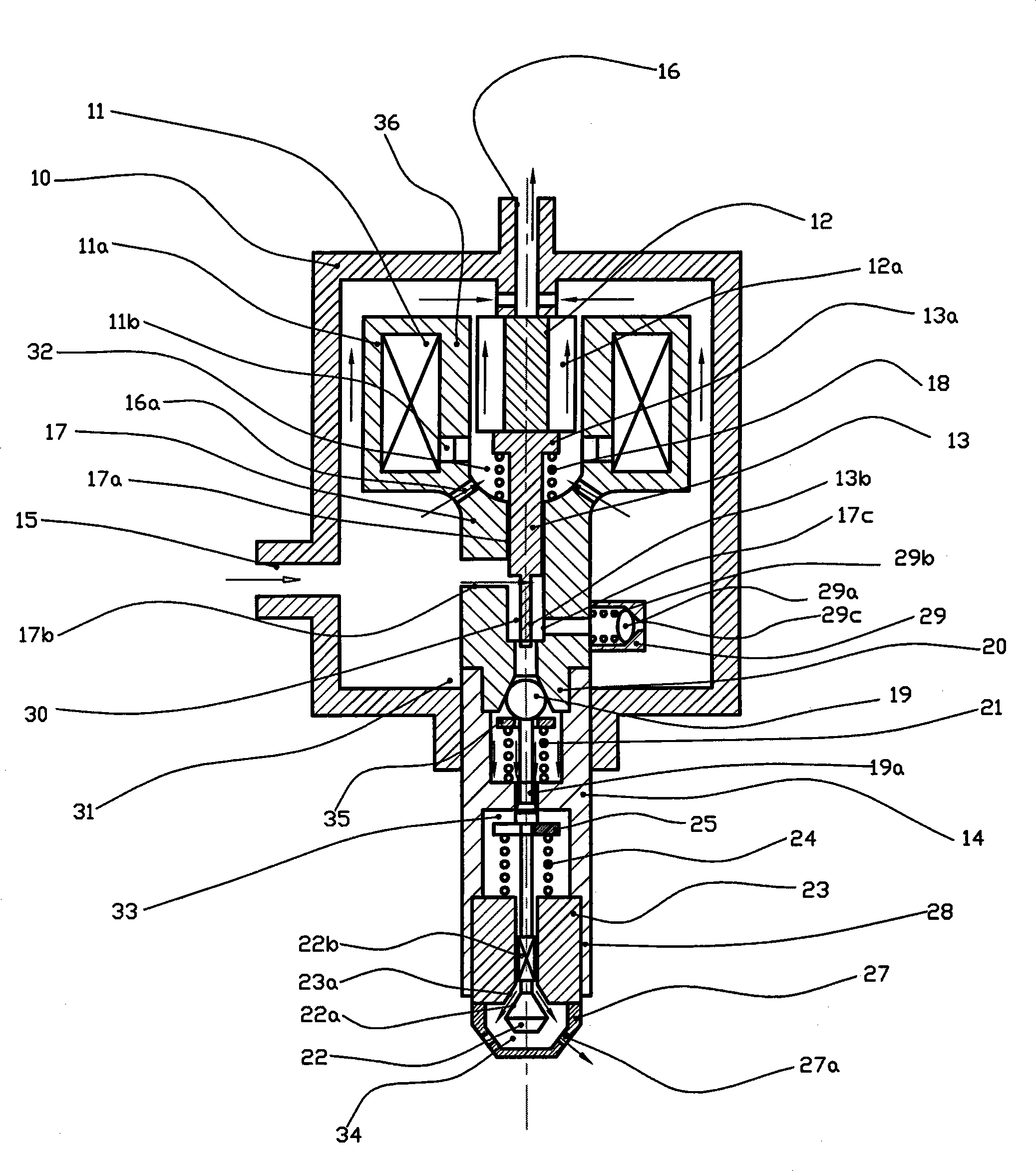

[0024] Embodiment 1: as figure 1 As shown, the electronic fuel injection device of the present invention includes: an oil casing 10, a coil 11, an approximately cylindrical armature 12, an approximately cylindrical plunger 13, a nozzle 14, an oil inlet 15, an Oil return port 16, a sleeve 17 that approximates a round hole.

[0025] The plunger 13 fits precisely with the inner hole 17a of the sleeve 17 and can move freely therein. The space formed by the lower end of the plunger 13 and the inner wall of the sleeve 17 is a pressure chamber 30, and the space between the oil casing 10, the coil 11 and the outer wall of the sleeve 17 A fuel chamber 31 is formed.

[0026] The side wall of the sleeve 17 is provided with a suction overflow hole 17b and an oil inlet valve hole 17c, and its lower end is provided with an oil outlet valve 35 composed of an oil outlet valve core 19, an oil outlet valve seat 20 and an oil outlet valve spring 21. The suction overflow hole 17b is located at ...

Embodiment 2

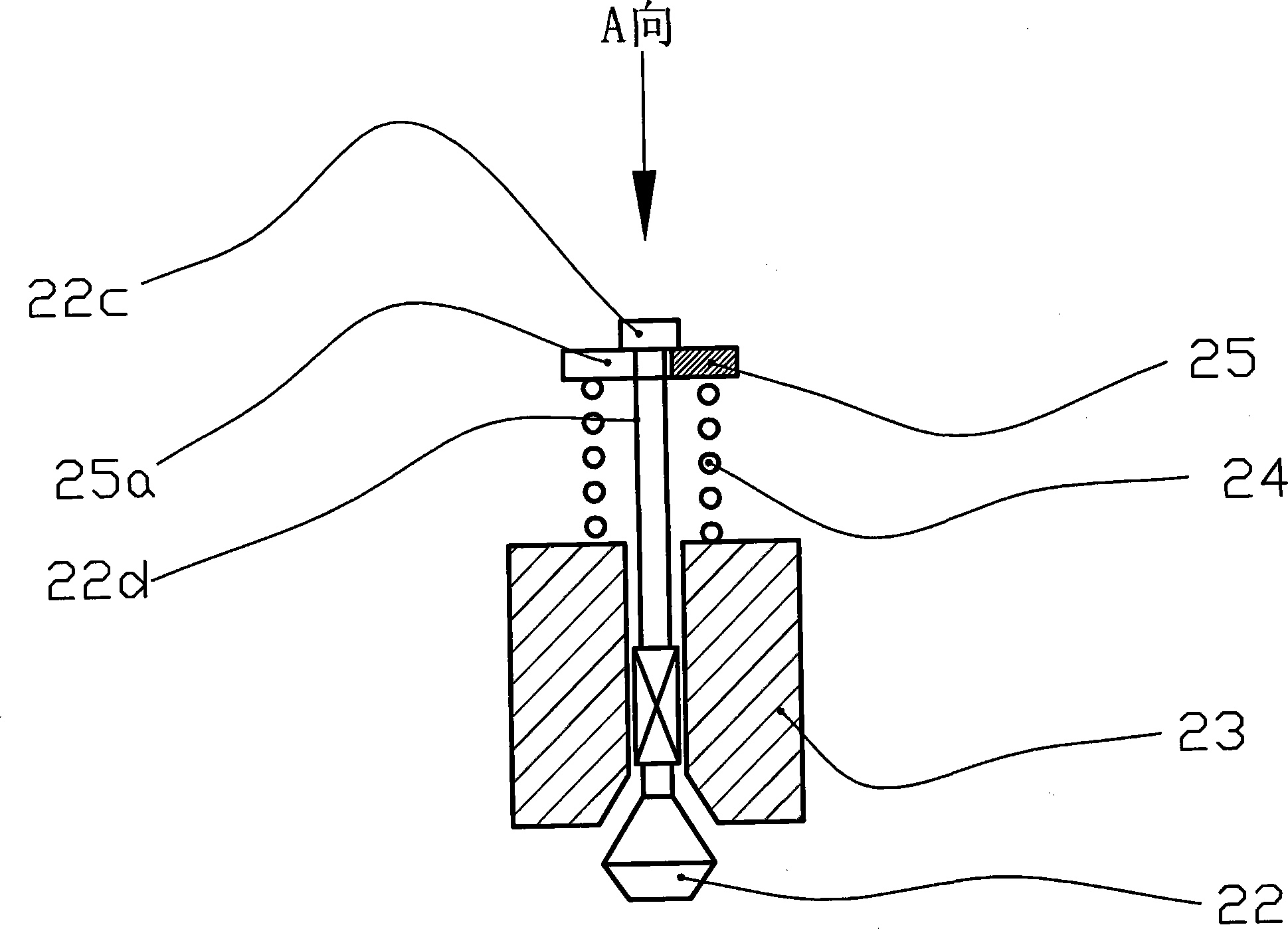

[0045] Embodiment 2: as Figure 4 , Figure 5 In the shown nozzle valve, the structure difference from Embodiment 1 is: the tail of the nozzle valve body 22 has a boss 22c that is approximately cuboid and a thin rod 22d; the center of the spring seat 25 of the nozzle valve has a shape similar to the boss 22c. The rectangular middle hole 25b; the boss 22c can pass through the rectangular middle hole 25b smoothly, and after being rotated at an angle, it is pressed against the nozzle valve body 22 under the pressure of the nozzle valve spring 24 .

Embodiment 3

[0046] Embodiment 3: as Figure 6 In the nozzle valve shown, the structure difference from Embodiment 1 is: there is a thin rod 22d at the end of the nozzle valve body 22, and there is a central hole 25c in the center of the nozzle valve spring seat 25, which is similar in shape to the thin rod, and the thin rod 22d penetrates the central hole In 25c, the end faces of the two are approximately flush, and welding is performed at the seams of the two.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap