Multipurpose engine equipped with a canister

A technology of poison filter and engine, which is applied in the direction of machines/engines, engine components, combustion engines, etc., and can solve the problems of reduced adsorption efficiency and poor ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, aspects of the present invention will be explained through embodiments based on the drawings. However, dimensions, materials, shapes, relative arrangements, etc. will be used for illustration only, and should not be construed as limiting the scope of the present invention unless any particular mention is made.

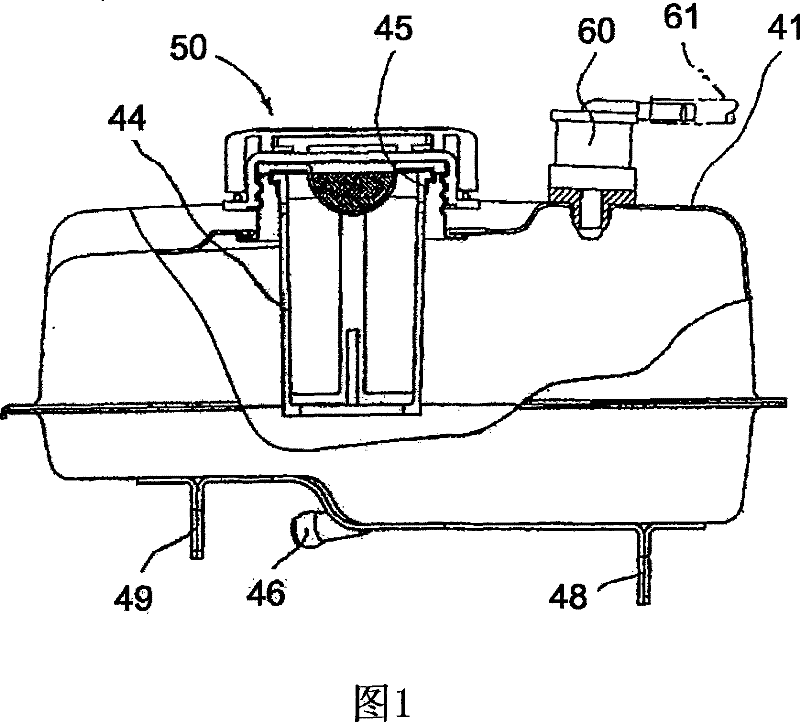

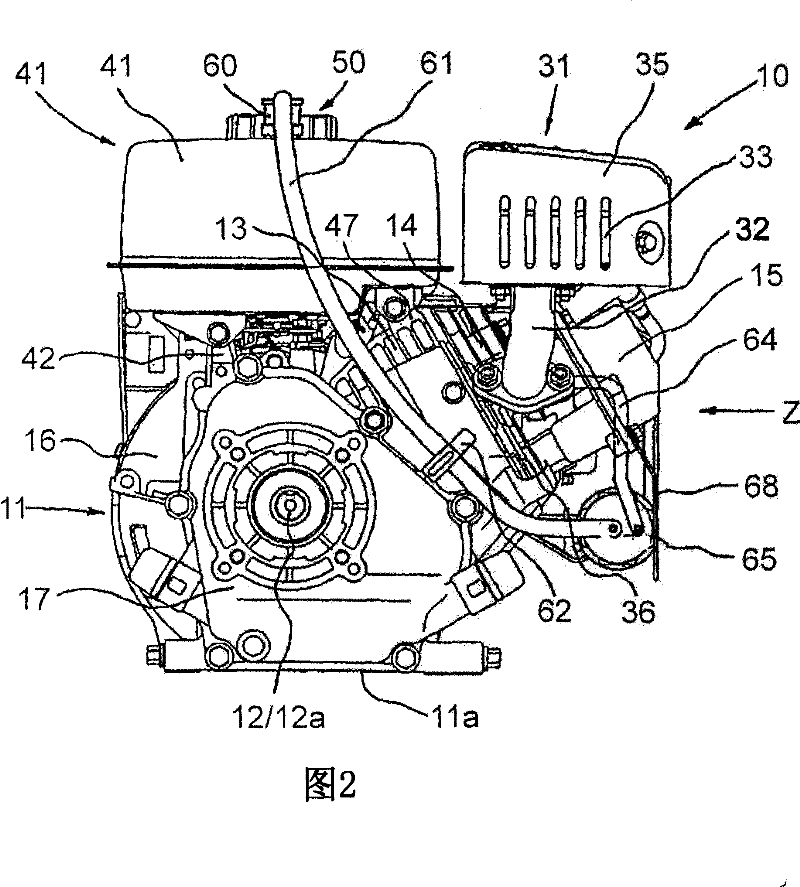

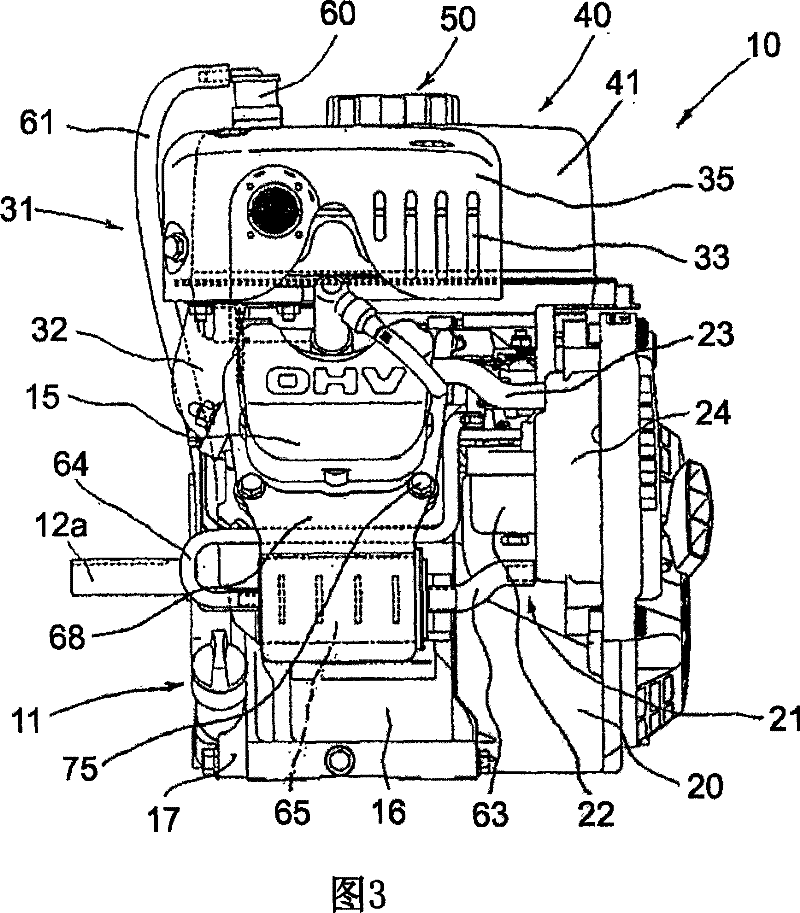

[0026] figure 1 is a partially cutaway side view of a fuel tank according to an embodiment of the present invention, with the tank cap and the vicinity of the fuel supply port shown in cross section. figure 2 is a front view of a multi-purpose engine capable of being compliant with transpiration gas regulations in accordance with the present invention. image 3 From figure 2 Side view of the engine seen in the direction of the Z arrow. Figure 4 is a cross-sectional view of the box cap assembly without the attachment cords to prevent it from falling out.

[0027] figure 2 and 3 The utility engine 10 in is, for example, an air-cooled single-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com