Motor bus unitary body with large-sized rectangular tube underframe

A rectangular tube, bus technology, applied in the direction of load-bearing body structure, vehicle parts, superstructure, etc., can solve the problems of complex process, poor rollover resistance, low cost, etc., and achieves simple production process, strong anti-collision, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

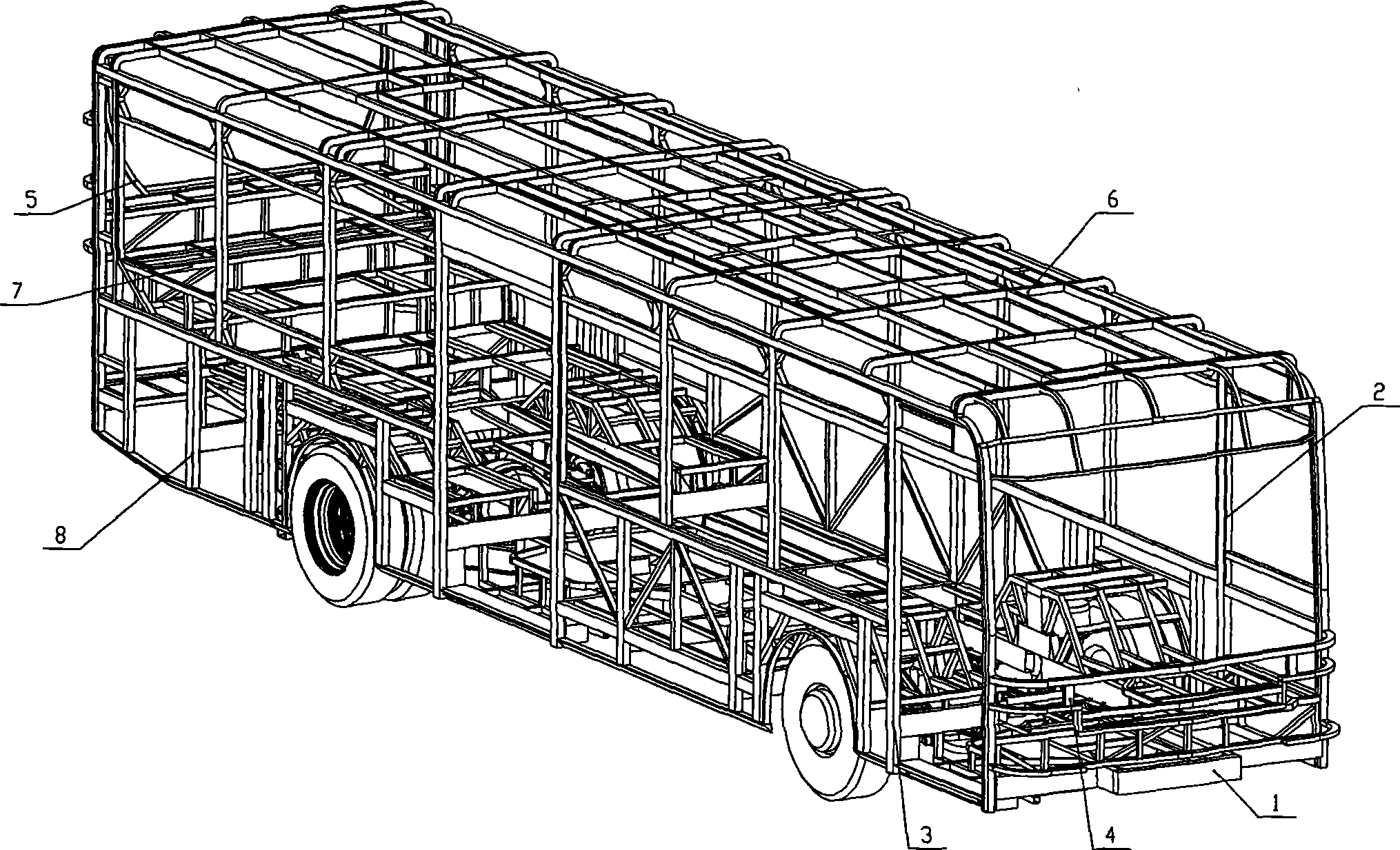

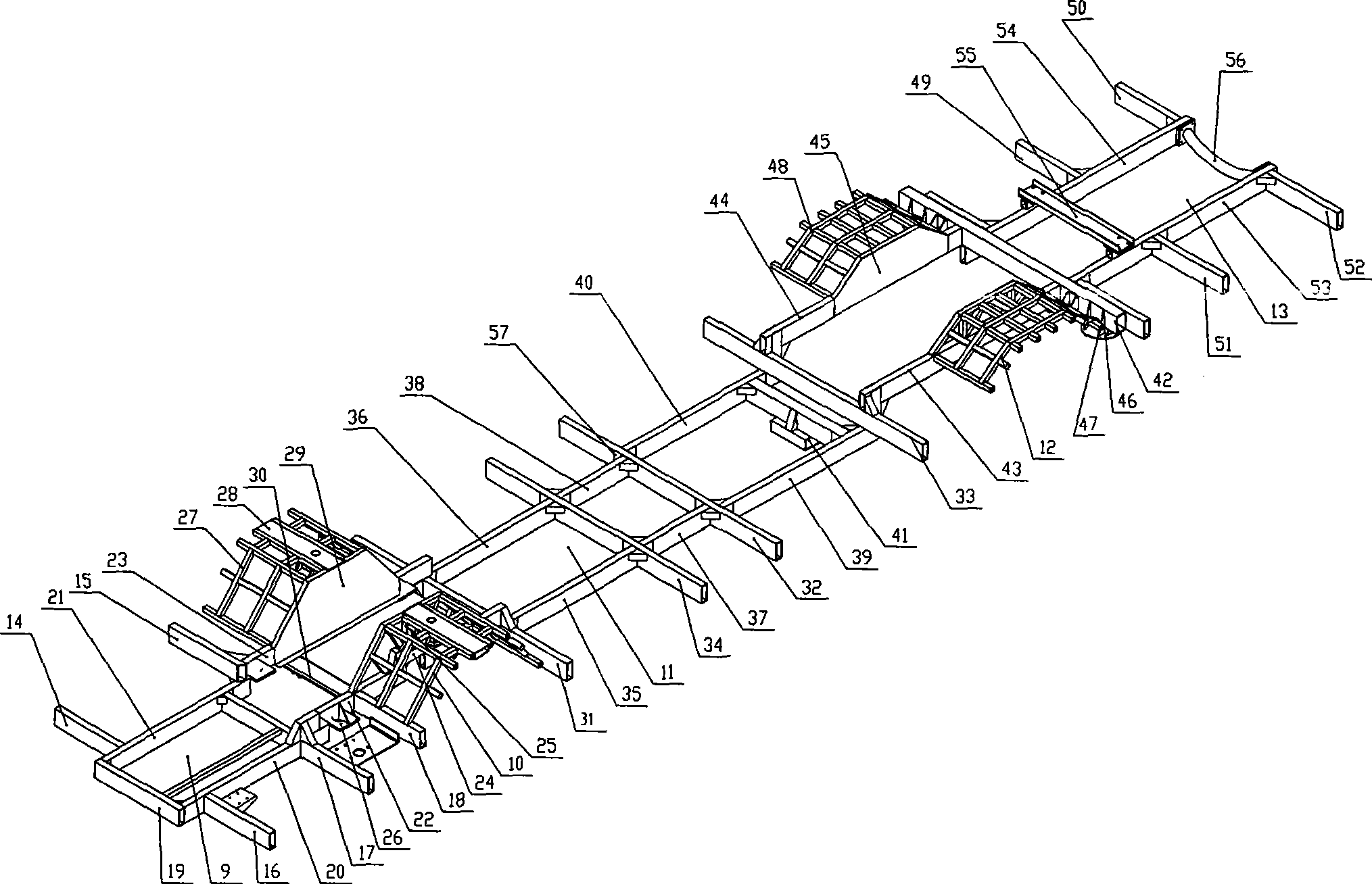

[0044] Below in conjunction with accompanying drawing, the example of 12 meters of two-stepped buses of the present invention is described in further detail:

[0045] Such as figure 1 As shown, the underframe 1 is connected with the upper body frame 8, the upper body frame 8 is connected with the top cover 6, and the underframe 1 is provided with a floor frame 7; as figure 2 As shown, the underframe 1 is composed of five design units (modules) connected in sequence: front suspension 9, front axle and front wheel housing 10, middle section 11, rear axle and rear wheel housing 12, and rear suspension 13 for installing the powertrain. composition. The upper body frame 8 includes the front and rear walls 4, 5 and the left and right side walls 2, 3 (left and right side frames); the underframe 1 and the body front and rear walls 4, 5, the left and right side walls 2, 3 and the top cover 6 are formed by connecting each node An integral bearing frame forms several closed force ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com