Automatic analyzer

An automatic analysis device and container technology, which is applied to the analysis of materials, instruments, biological tests, etc., can solve problems such as incorrect measurement, calculation of concentration by calibration curve, and decline in the accuracy of standard sample measurement, and achieve high-precision analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

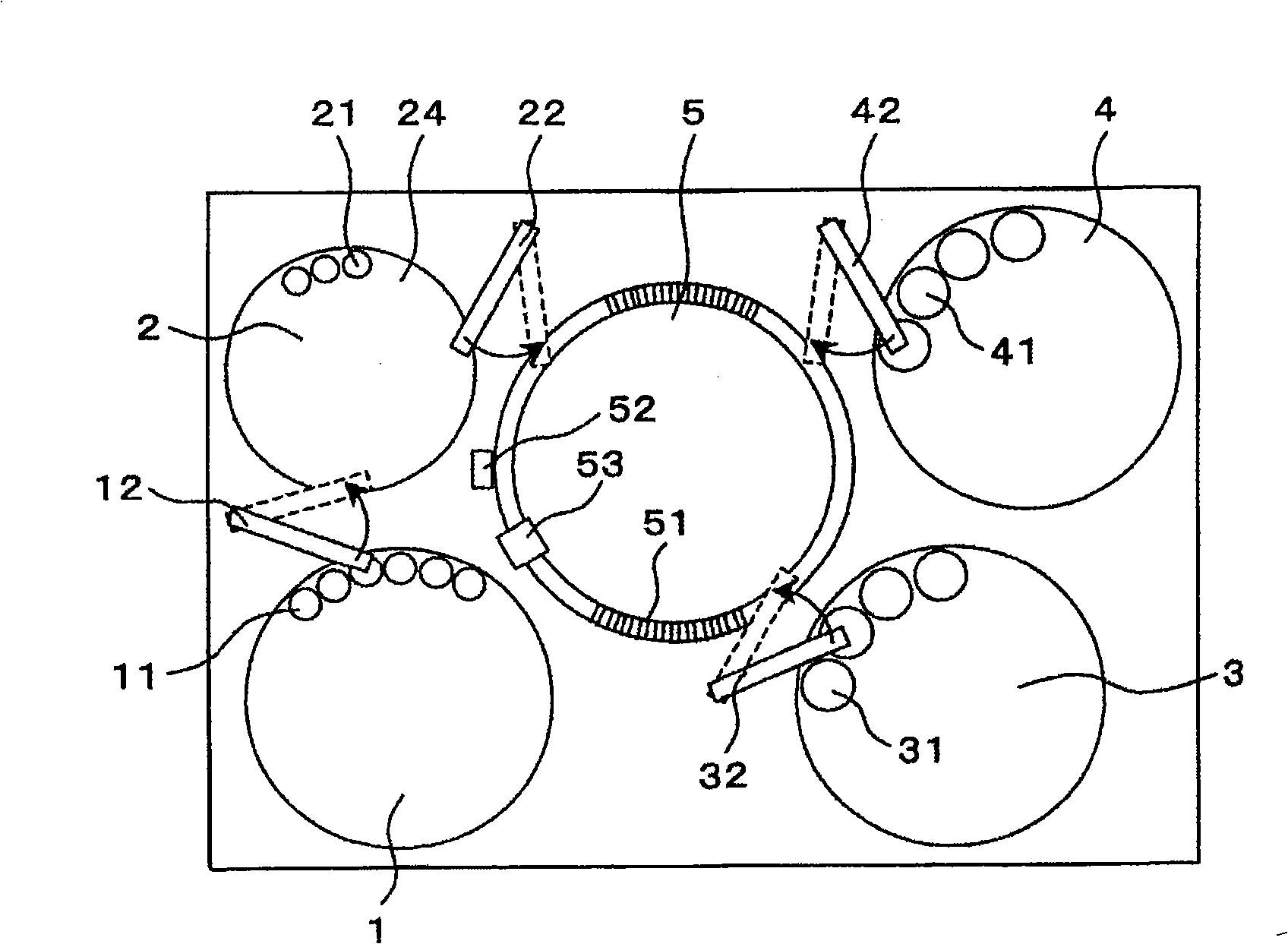

[0023] figure 1 It is a diagram showing the overall structure of the automatic analyzer of the first embodiment. The automatic analysis device of the present invention has: the sample plate 1 of the sampling container that fixedly puts the sampling container of the living body source sample, and the sampling sample plate (also called sample table) 2, the first reagent disc 3 and the second reagent disc 4 that fix the plurality of sample containers that are put into the reagent, the sample that will be dispensed from the sample container of the sample disc 2 and the sample from the first reagent disc. The reagents dispensed from the reagent containers of the reagent disc and the second reagent disc are put into the reaction tank to make the reaction disc 5 react.

[0024] For example, 100 sampling containers 11 in two rows are fixed on the sample tray 1, and are fed step by step at a predetermined speed. A predetermined amount of the sample in the sampling container 11 is asp...

Embodiment 2

[0031] A second embodiment of the present invention will be described below.

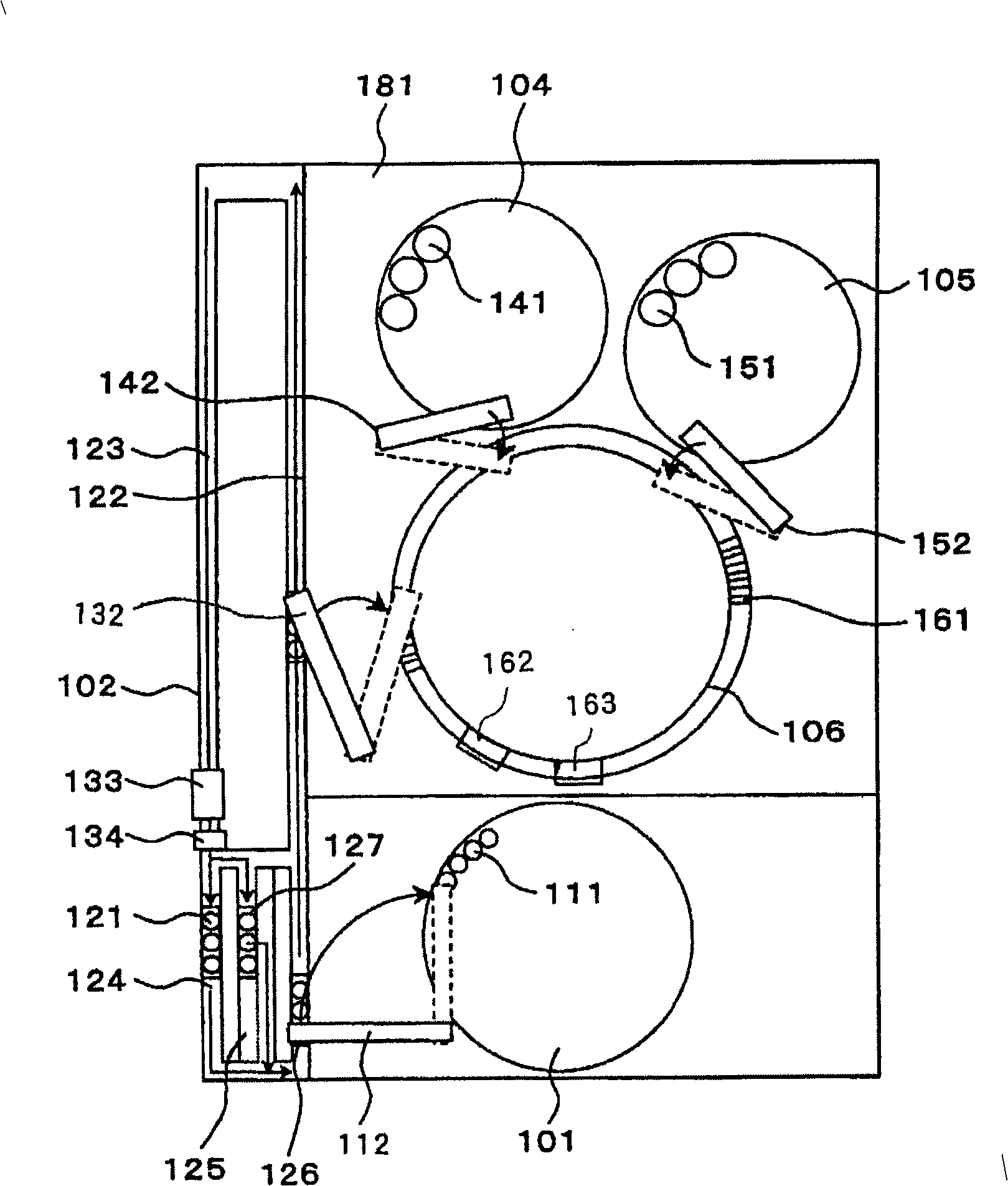

[0032] image 3It is a figure showing the overall structure of the automatic analyzer of the second embodiment. The automatic analysis device of the present invention has: a sample disc 101 for holding a sampling container 111 containing a sample from a living body; , the first reagent disc 104 and the second reagent disc 105 that fix the plurality of reagent containers in which the reagents are placed, the samples dispensed from the sample containers on the dispensing sample transport line 102 and the samples from the first reagent disc, the second reagent disc The reagents dispensed from the reagent containers of the second reagent disc are placed in the reaction tank and reacted in the reaction disc 106 . In addition, a plurality of analysis units 181 including the first tray 104 , the second tray 105 , and the reaction tray 106 may be arranged along the dispensing sample transfer line 102 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com