Sensor calibrating device

A technology for calibrating devices and sensors, applied to instruments and other directions, can solve the problems of slow heating speed, long calibration time, low calibration efficiency, etc., to avoid explosion, facilitate air circulation, and speed up air circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

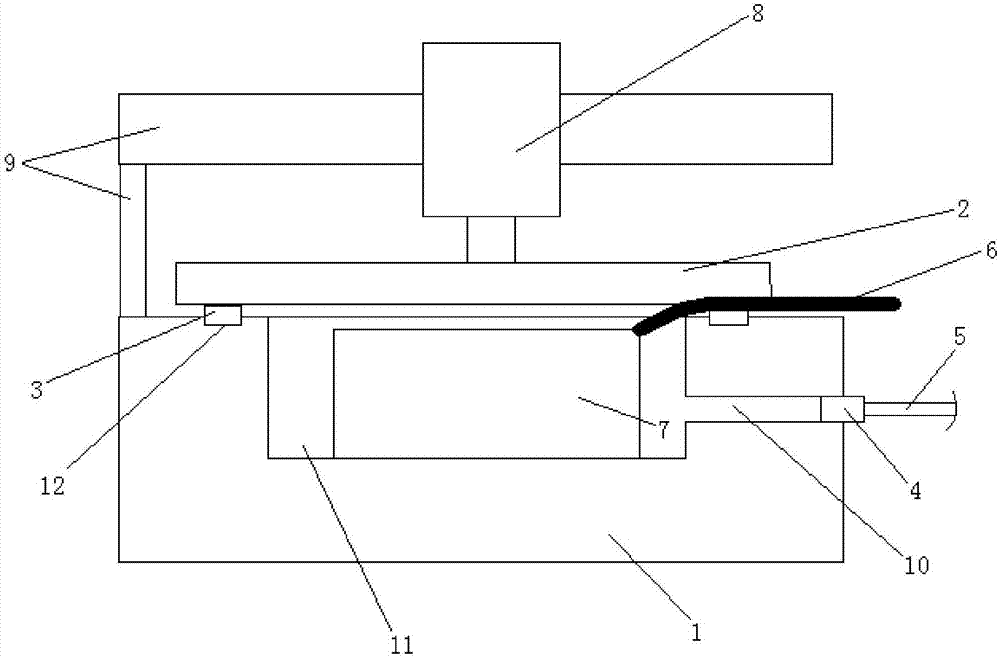

[0023] like figure 1 As shown, this embodiment provides a sensor calibration device, including a temperature-adjustable oven (not shown in the figure), placed in the oven and provided with a base 1 for placing a sensor module with a placement groove 11, capable of A cover plate 2 for sealing the placement slot 11 , and a driving assembly 8 for driving the cover plate 2 to open and sealing the opening of the placement slot 11 .

[0024] In this embodiment, the drive assembly 8 drives the cover plate 2 to move, so as to seal or open the opening of the placement groove 11. During the heating process of the oven, the cover plate 2 is driven to move by the driving assembly 8 to remove the cover plate 2 from the opening of the placement groove 11, so as to facilitate the air circulation in the placement groove 11, accelerate the air circulation speed, and reduce the sensor module. The time required for the environment to be heated to the corresponding temperature; during the calibr...

Embodiment 2

[0033] The difference between this embodiment and the first embodiment lies in that the fixed position of the driving assembly 8 is different. In this embodiment, the drive assembly 8 is fixed on the inner wall of the oven, the cover plate 2 is connected to the protruding end of the drive assembly 8, and the drive assembly 8 drives the cover plate 2 to open and seal the opening of the placement groove 11 .

Embodiment 3

[0035] The difference between this embodiment and the first embodiment lies in that the moving direction of the cover plate 2 is different, and correspondingly the protruding direction of the protruding end of the driving assembly 8 is also different. Specifically, the support frame 9 is arranged on one side of the upper end surface of the base 1, the drive assembly 8 is fixed on the support frame 9 and the protruding end of the drive assembly 8 is parallel to the bottom of the base 1. The upper end surface is arranged, and the cover plate 2 can be driven to move left and right or forward and backward through the driving assembly 8, so as to facilitate the opening of the cover plate 2 and seal the opening of the placing groove 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com