Smoke gas detection rod system error eliminating device in calibration process of smoke gas analysis instrument

A flue gas analyzer and system error technology, applied in the direction of analyzing gas mixtures, standard gas analyzers, measuring devices, etc., can solve the problem of not connecting the flue gas probe rod, ignoring the adsorption effect of the flue gas probe rod, inaccurate calibration results, etc. problems, to achieve the effect of improving the scope of use, simple and reasonable structure settings, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

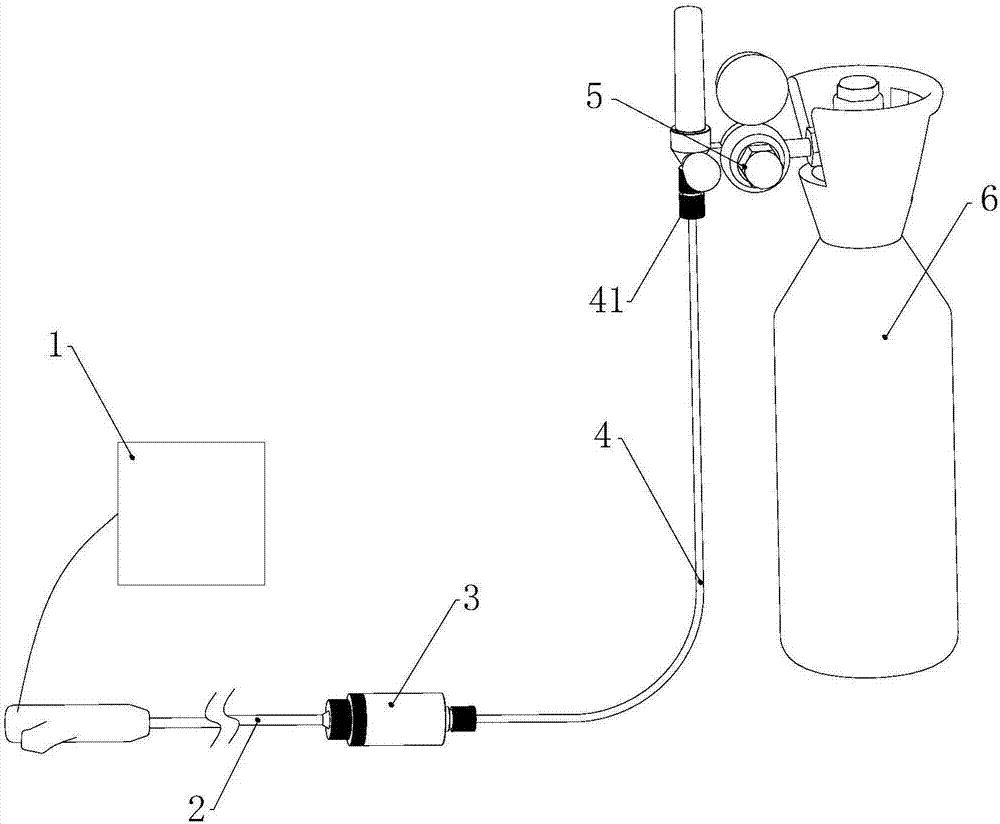

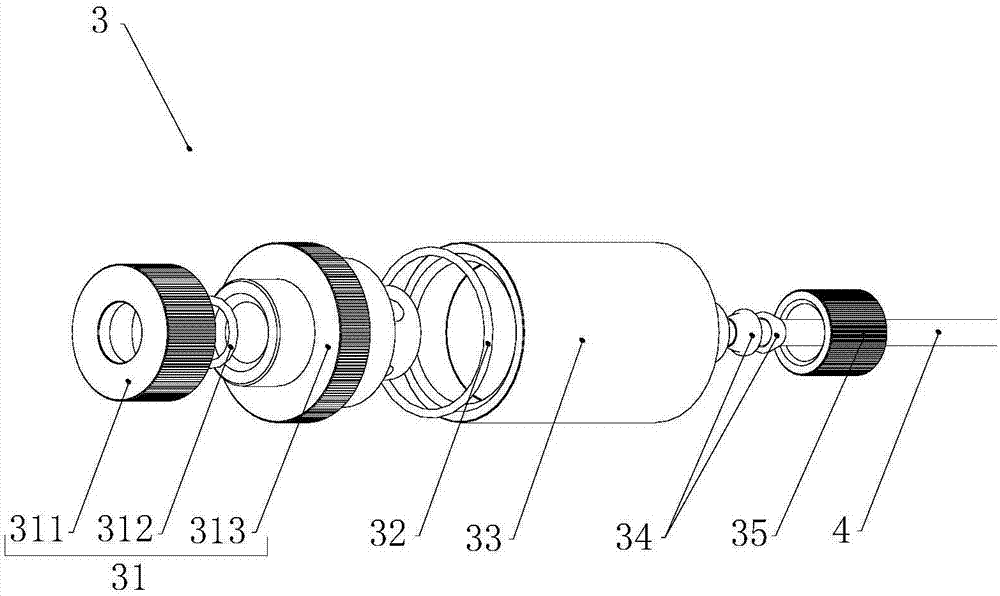

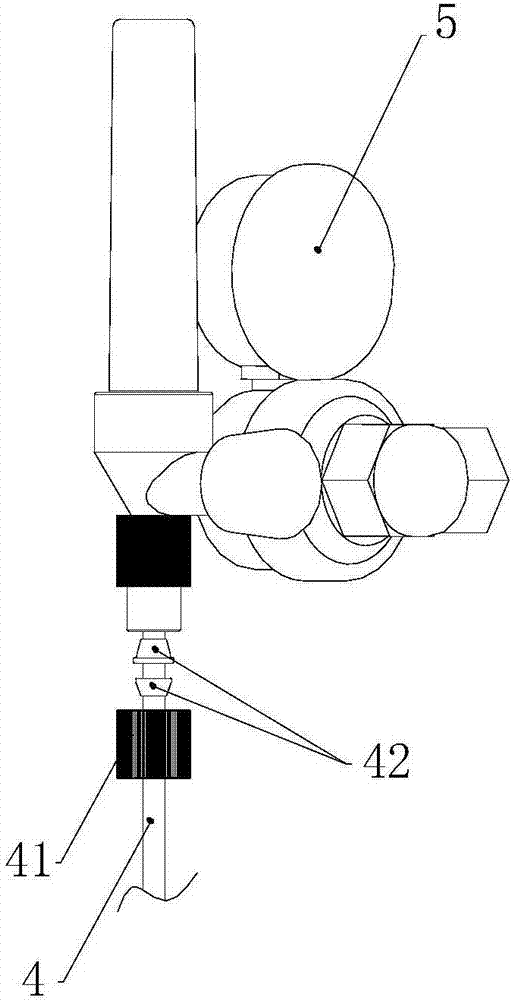

[0030] Such as figure 1 and figure 2 As shown, the device for eliminating the error of the flue gas probe system during the calibration process of the flue gas analyzer includes a buffer cylinder 3, a calibration gas pipe 4 and a pressure reducing valve 5, and the end of the buffer cylinder 3 far away from the calibration gas pipe 4 is connected with Smoke probe 2; the buffer cylinder 3 includes an adapter 31, a gas chamber 33 and a second sealing screw cover 35, one end of the adapter 31 is fixedly connected to one end of the probe of the smoke probe 2, and the adapter The other end of the joint 31 protrudes into the gas chamber 33 and is fixedly connected to the gas chamber 33 , and the end of the gas chamber 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com