Automatic calibration device and method for standard metal meter

A standard metal gauge and automatic calibration technology, applied in the field of measurement, can solve the problems of manpower consumption, time, human influence on readings, long constant temperature time, etc., and achieve the effect of automatic operation, saving recording time and saving operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

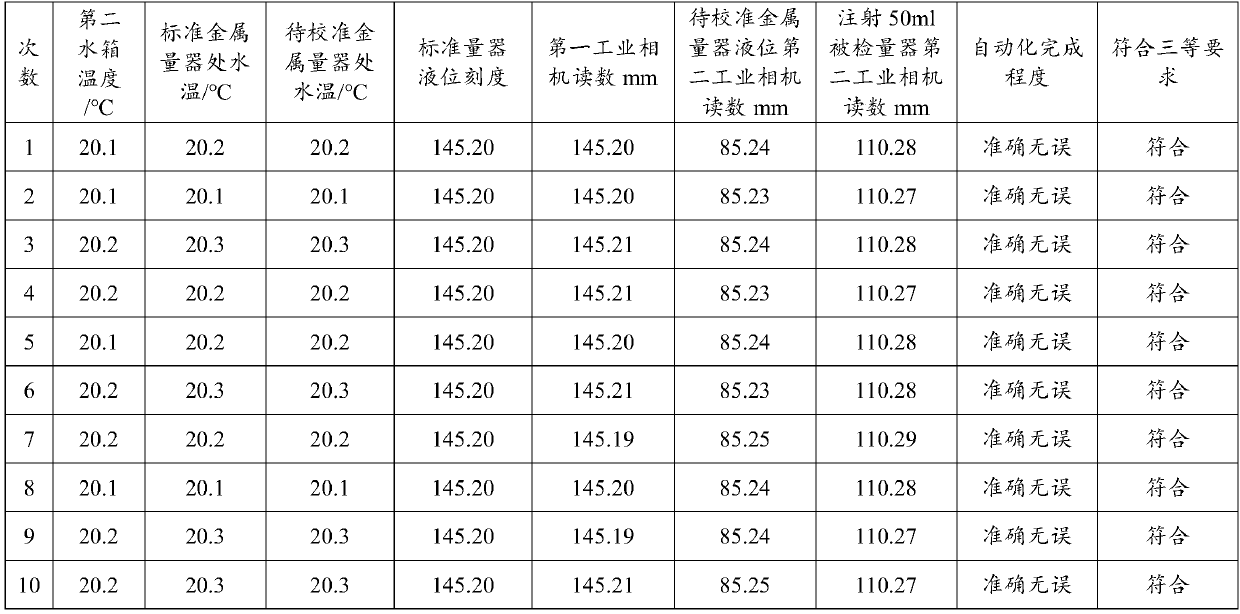

Examples

Embodiment 1

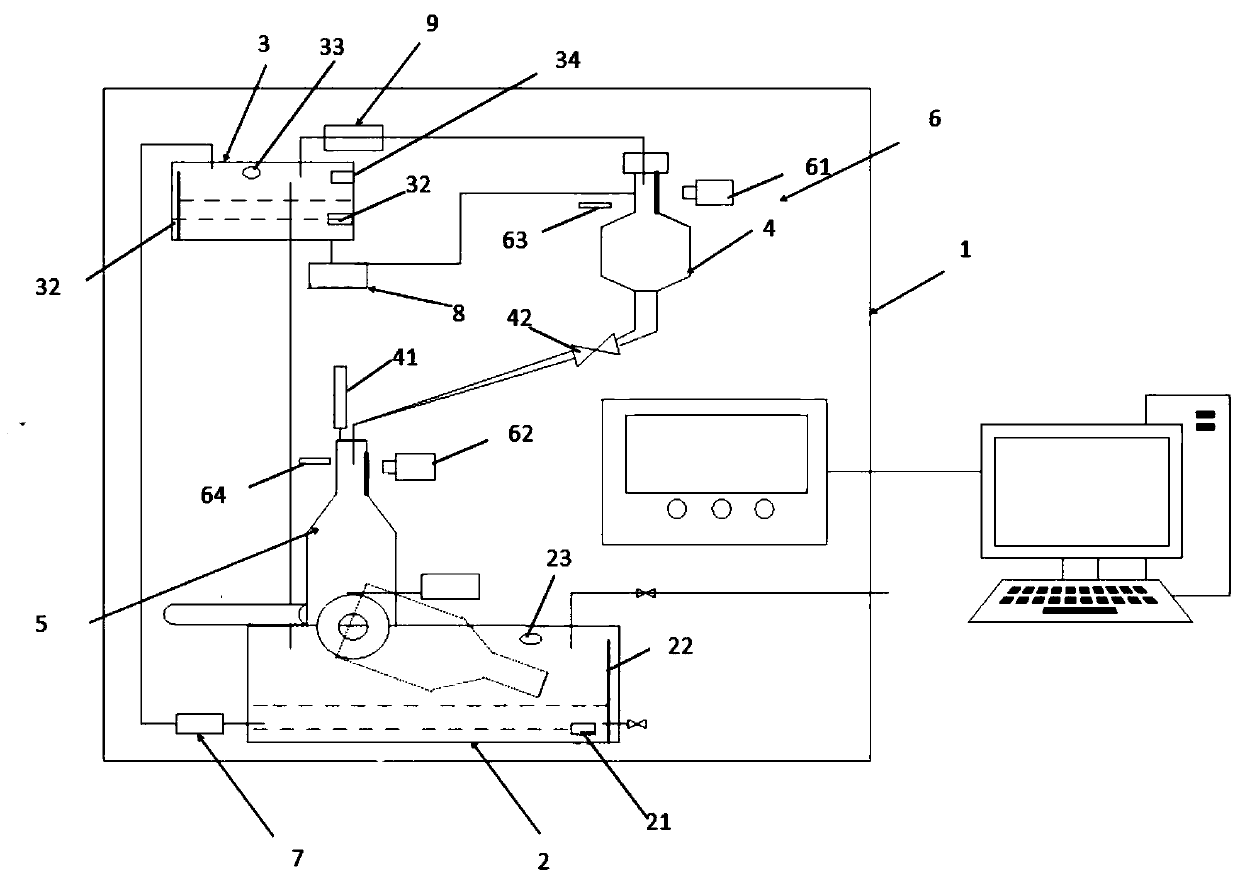

[0042] The first embodiment provides an automatic calibration device for standard metal gauges,

[0043] Such as figure 1 As shown, the device includes: a housing 1, a first water tank 2, a second water tank 3, a standard metal gauge 4, a metal gauge 5 to be calibrated, a monitoring mechanism 6 and a calibration control system;

[0044] The first water tank 2 is arranged at the bottom of the housing 1, the second water tank 3 is arranged at the top of the housing 1, and a water pump 7 is arranged between the first water tank 2 and the second water tank 3;

[0045] The standard metal gauge 4 is arranged on the support of the housing 1, the standard metal gauge 4 is connected to the second water tank 3, and the metal gauge 4 to be calibrated is arranged on the standard metal gauge 3 below;

[0046] The monitoring mechanism 6 includes a first industrial camera 61 and a second industrial camera 62, and the first industrial camera 61 is arranged on the bottleneck side of the stan...

Embodiment 2

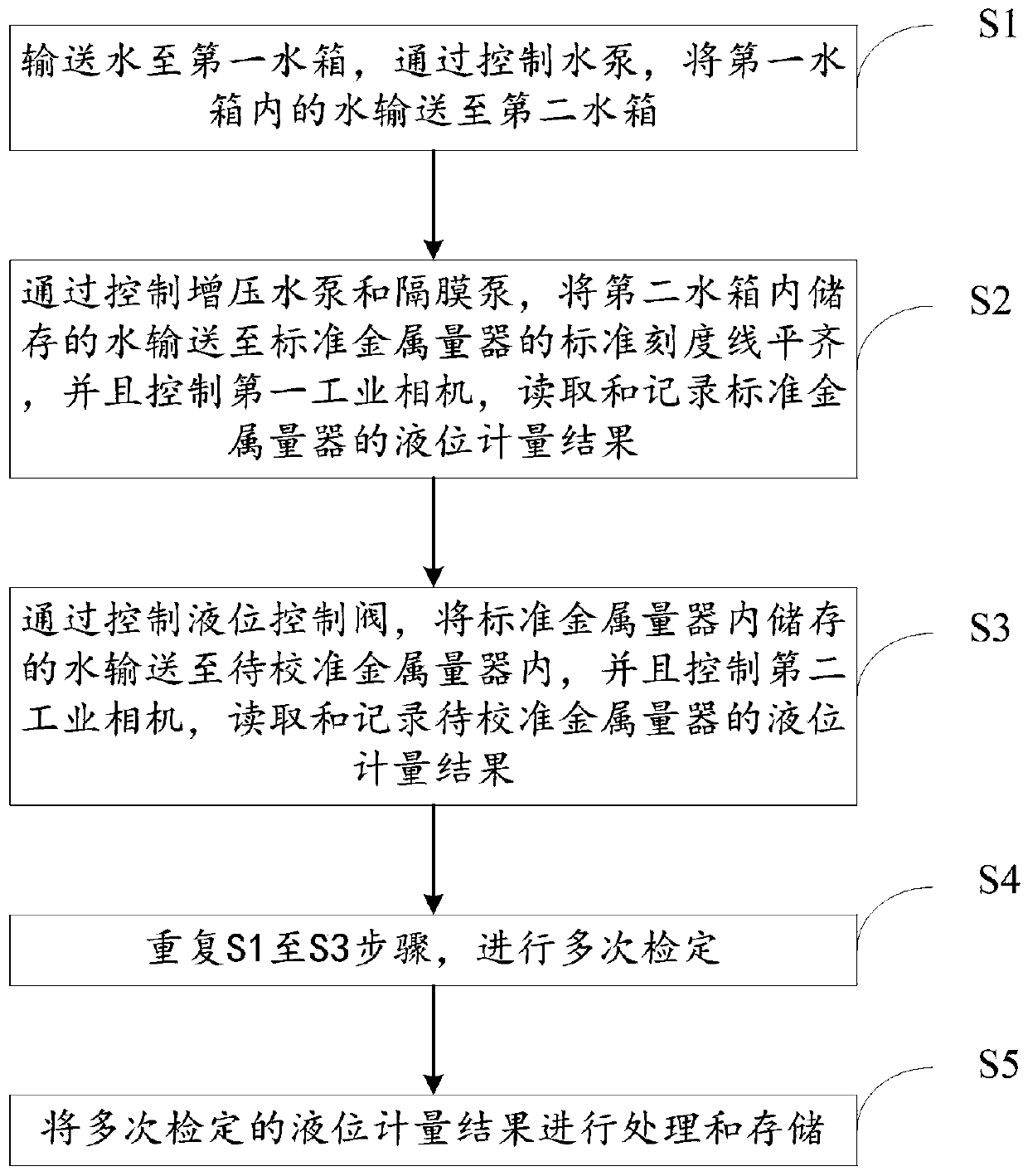

[0080] The second embodiment provides a method for automatic calibration of a standard metal gauge, comprising the following steps:

[0081] S1: Send water to the first water tank, and send the water in the first water tank to the second water tank by controlling the water pump.

[0082] Specifically, the S1 step also includes:

[0083] S101. Observing through the second visible liquid level, when the second water tank is insufficient, supplying water through the water pump;

[0084] S102. Constantly temperature the water in the first water tank and the second water tank for a period of time, and record the water temperature in the corresponding water tank through the first thermometer and the second thermometer;

[0085] S103. When the temperature of the second water tank is too high, control the temperature through the temperature controller.

[0086] Further, the water temperature of the first water tank and the second water tank is controlled at 20°C, with an allowable e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com