Esd type connector

An electrostatic discharge and connector technology, applied in the field of electrostatic discharge connectors, to avoid adverse effects and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

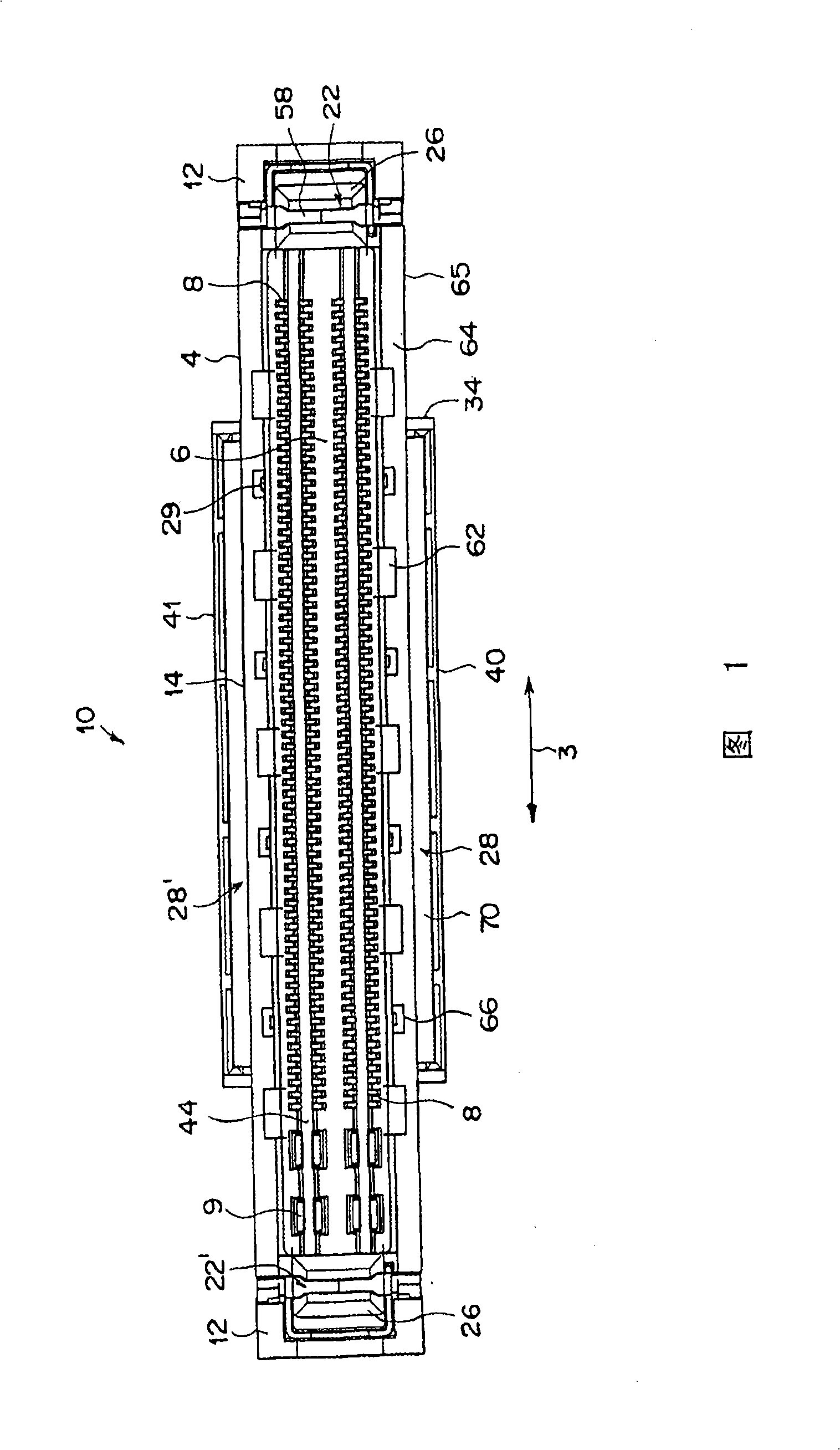

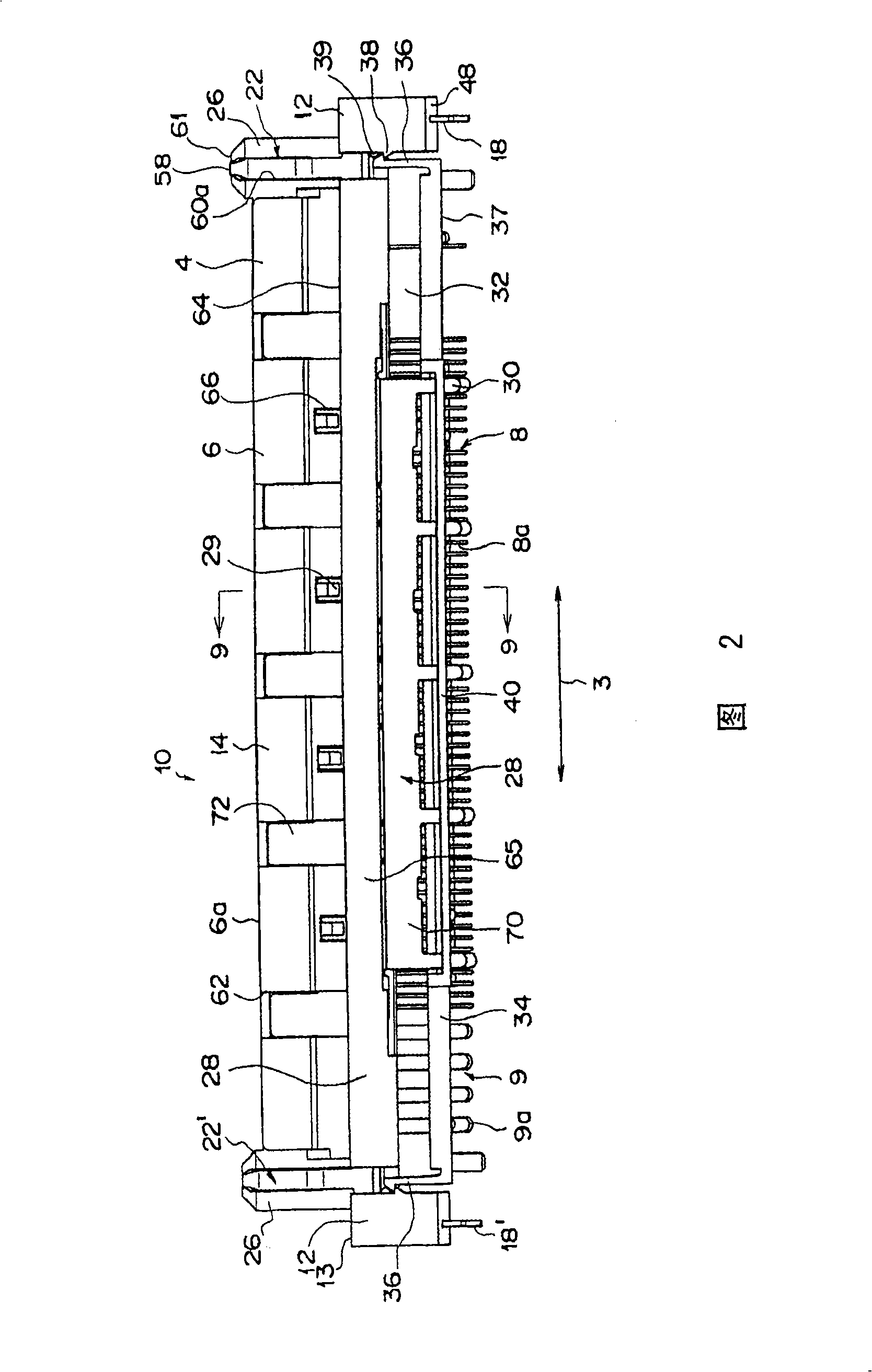

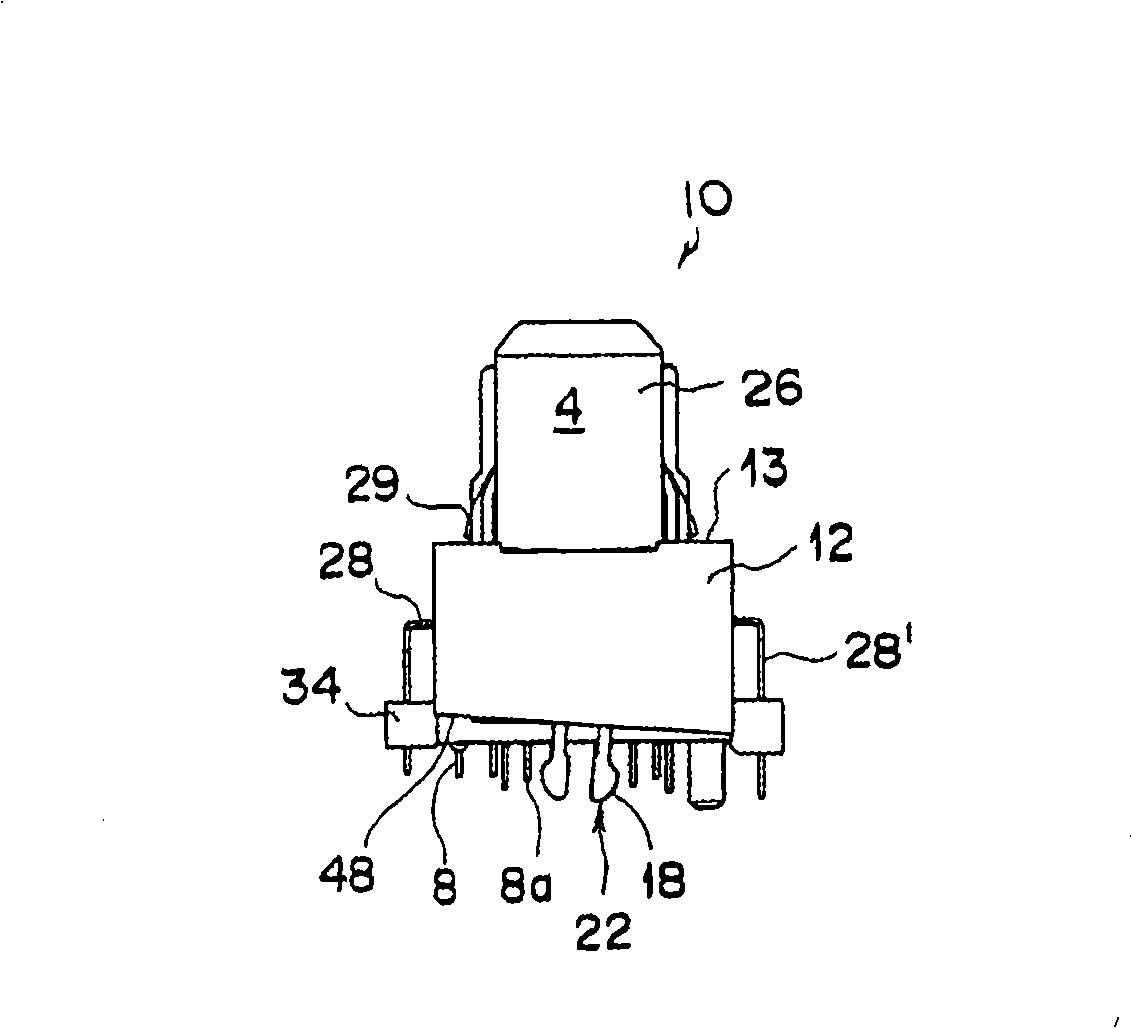

[0057] A preferred embodiment of the electrical connector of the present invention, that is, a plug connector (electrostatic discharge connector with guide bar), will be described in detail below with reference to the accompanying drawings. 1 to 4 show a plug connector 10 . Accompanying drawings 1, 2, 3 and 4 are plan view, front view, right side view and bottom view of the plug connector 10 respectively.

[0058] Description will be given below with reference to FIGS. 1 to 4 . The plug connector 10 comprises an elongated insulating housing 4 ; on a junction 6 of the housing 4 , contacts 8 and 9 arranged in four rows along the longitudinal direction 3 of the housing 4 . The contacts 8 are narrow contacts for signal transmission. The contacts 9 are wide contacts for the power supply. The housing 4 comprises a parallelepiped main body 14 extending in the longitudinal direction 3 and parallelepiped mounting portions 12 and 12 at both ends thereof. The main body 14 and the mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com