Dust removing device for vacuum cleaner

A technology of dust removal device and vacuum cleaner, which is applied in the direction of suction filter, etc., which can solve the problems that the dust removal efficiency of the first-level dust collector cannot be improved, increase the number of times users clean the dust cup, and affect the dust removal efficiency of the vacuum cleaner, so as to improve the dust removal efficiency and reduce cleaning The number of dust cups and the effect of avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

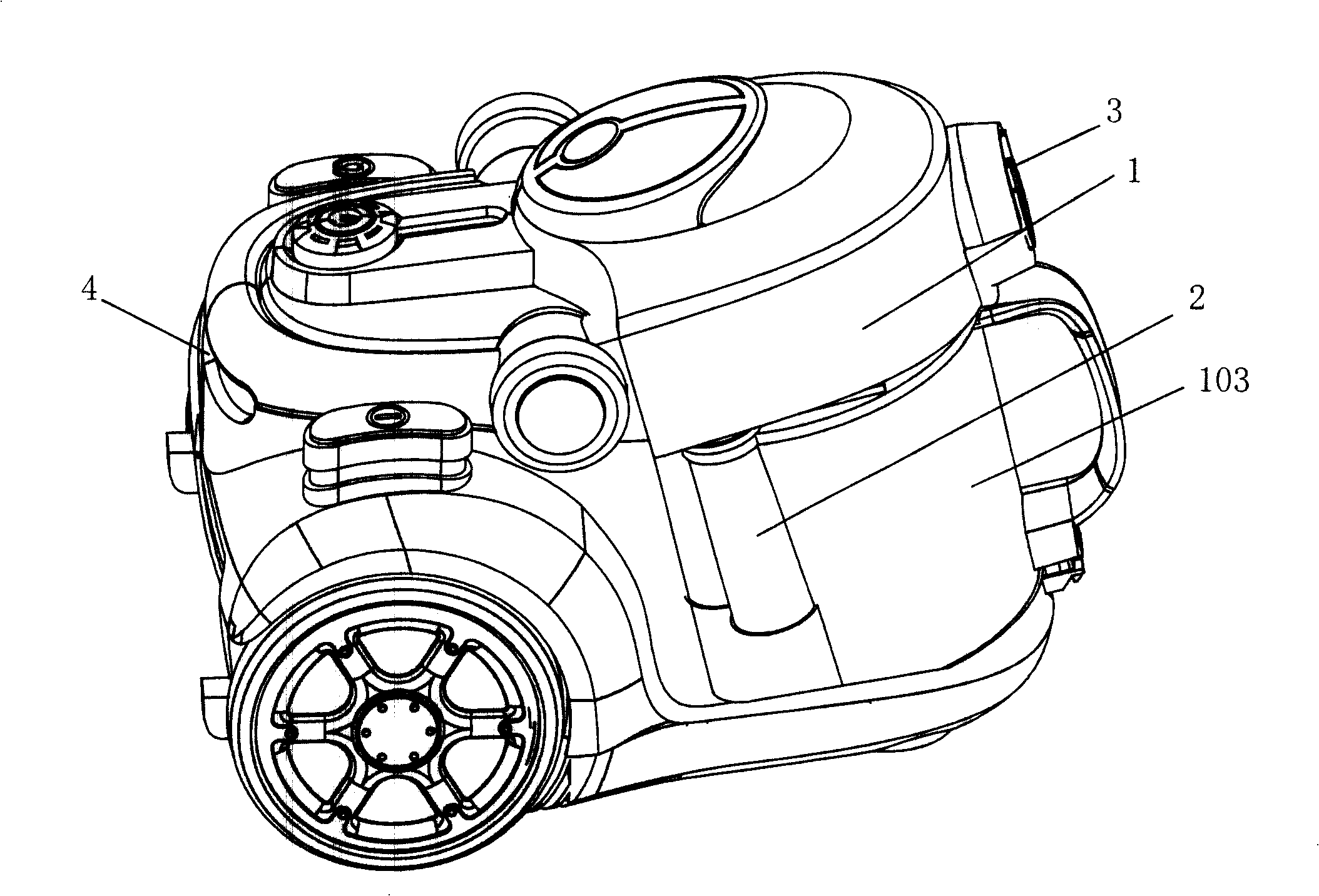

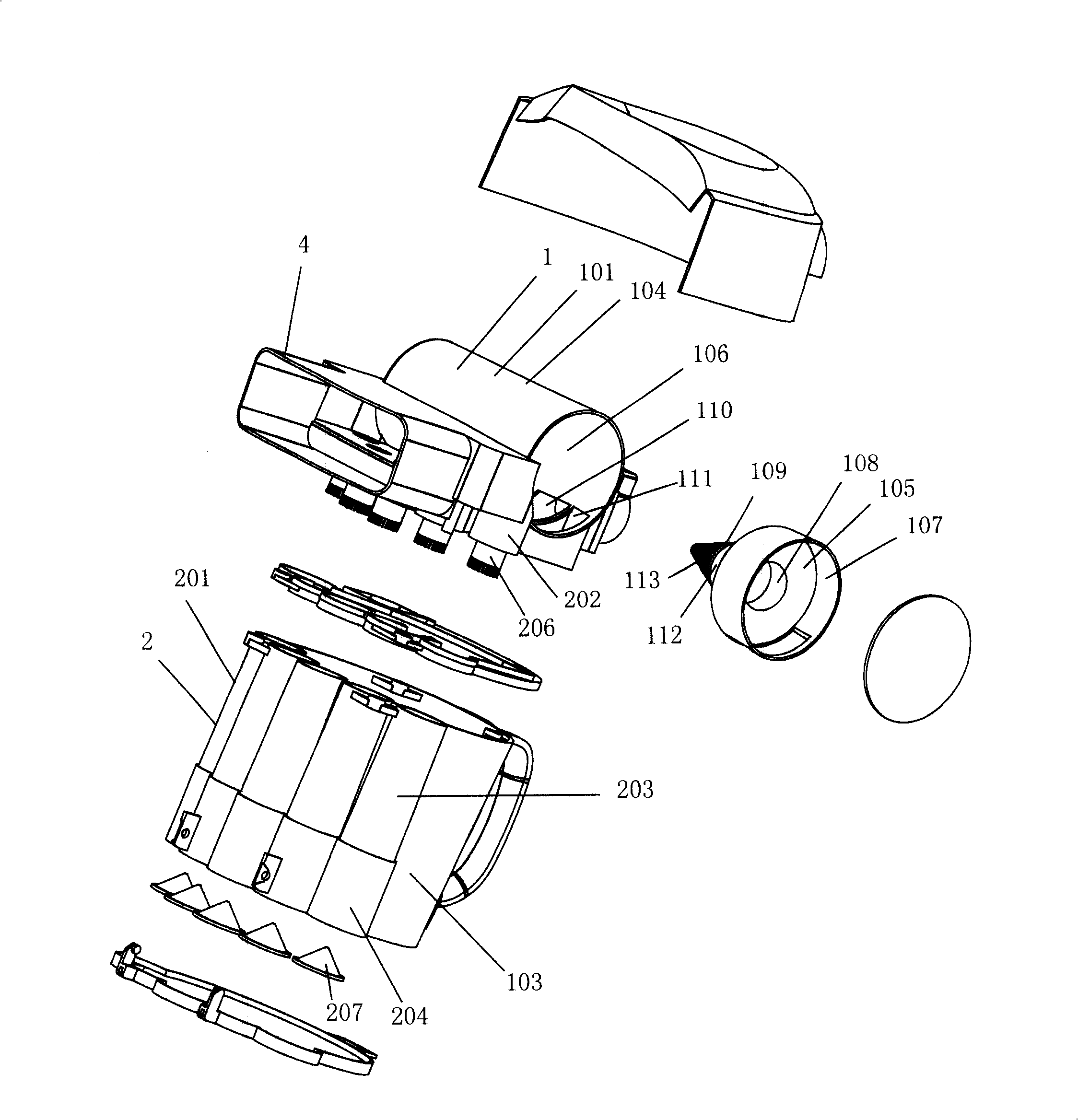

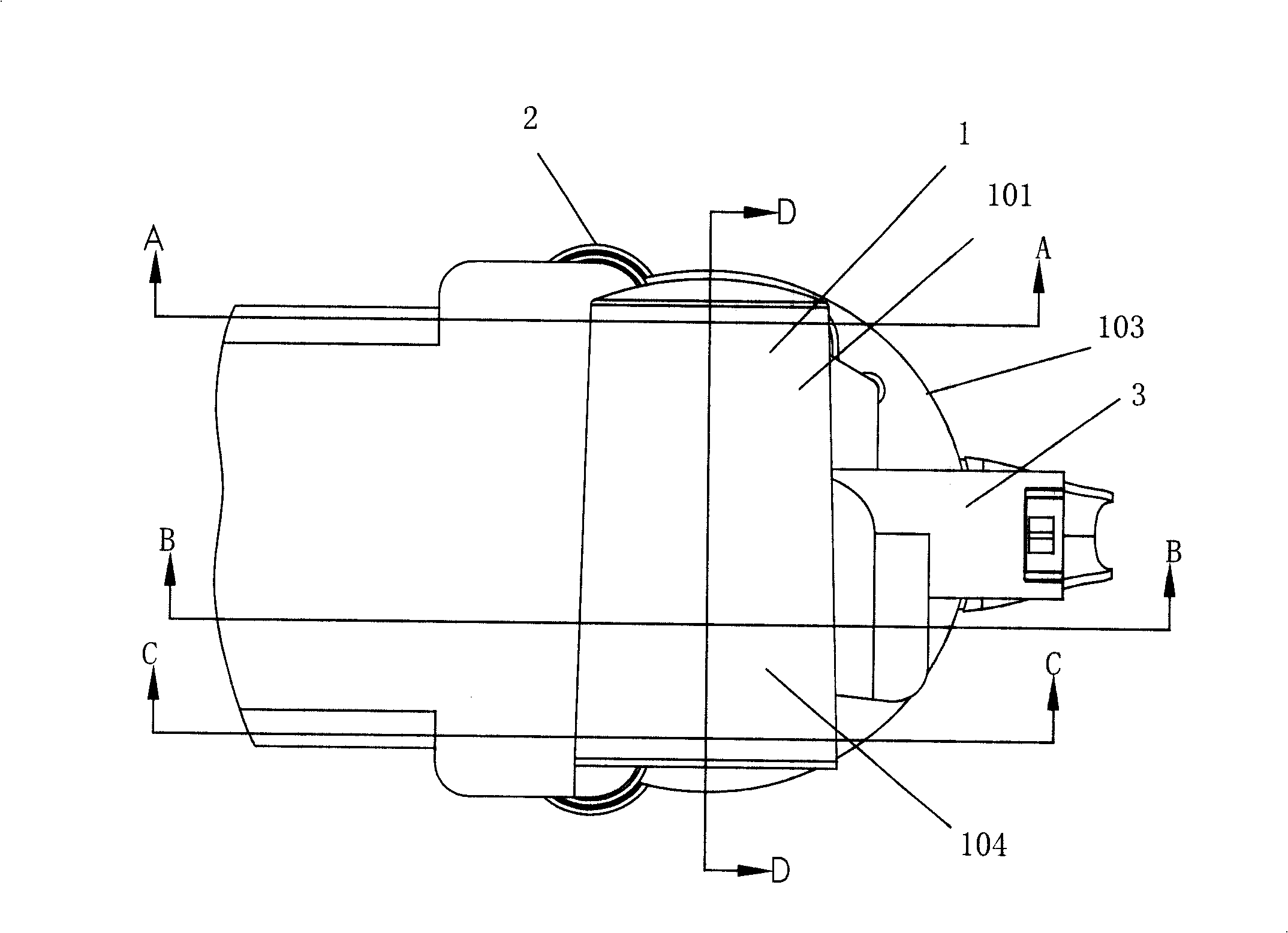

[0030] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a dust removal device for a vacuum cleaner includes a primary dust collector 1 and a secondary dust collector 2, the cyclone axis of the primary separation device 101 in the primary dust collector 1 and several of the secondary dust collectors 2 The cyclone axes of the secondary separation device 201 are arranged perpendicular to each other. The primary separation device 101 of the primary dust collector 1 is connected to the dust cup 103 through the dust outlet 102, and the primary separation device 101 is located outside the dust cup 103. The device 101 is arranged laterally on the upper part of the dust cup 103 , and the secondary separation device 201 is arranged longitudinally on the side of the dust cup 103 .

[0031] In the above embodiment, the primary separation device 101 includes a primary cyclone cylinder 104, the interior of the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com