Hydraulic safety valve

A safety valve and hydraulic technology, applied in the field of hydraulic safety valves, can solve problems such as mechanical troubles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

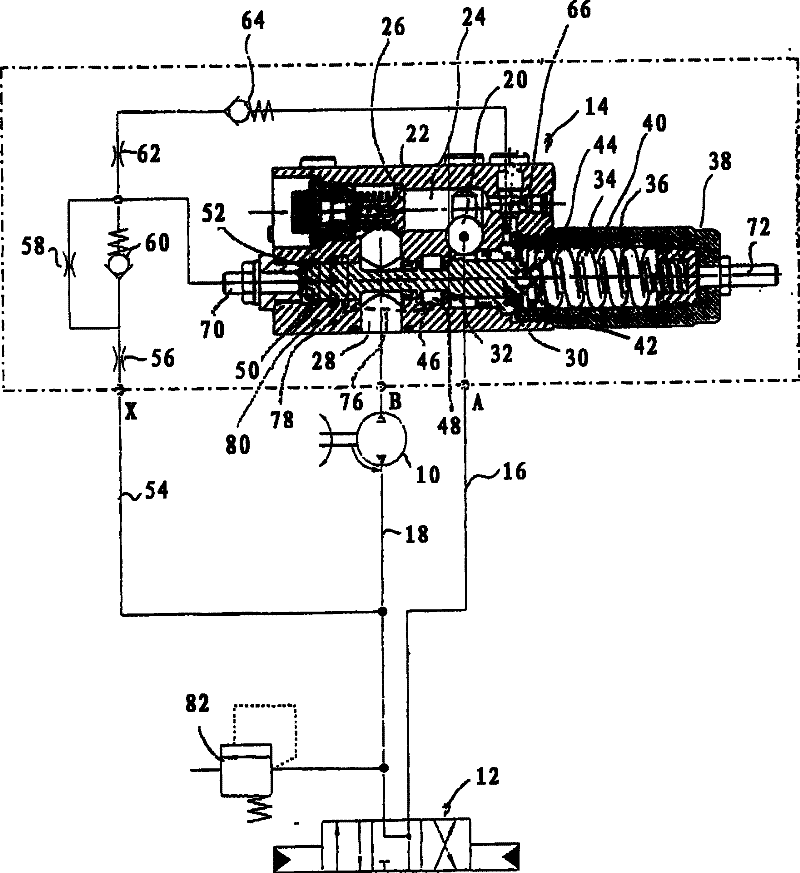

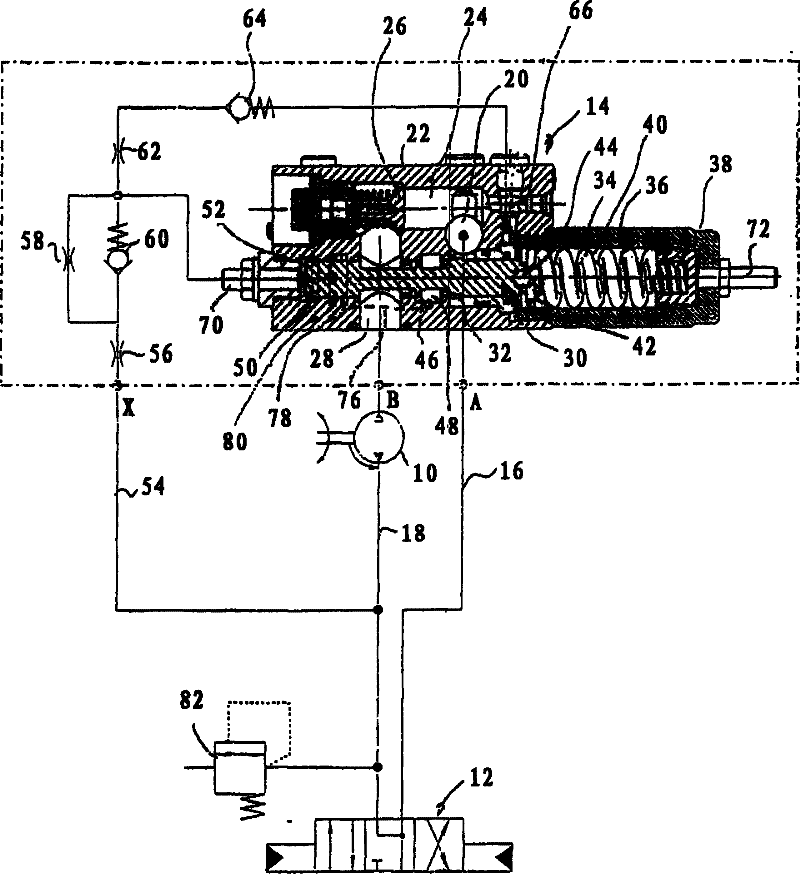

[0012] In the drawing, a hydraulic motor 10 is provided at 10 , which, for example, lifts a load not shown in detail. The motor 10 is controlled by a controller 12, for example a three-position valve, which is electromagnetically actuated. The pump supplying the motor 10 with oil and the associated oil tank are not shown. A safety valve 14 is provided between the controller 12 and the motor 10 . An up line 16 and a down line 18 are located between the safety valve 14 and the controller 12 . The ascending line 16 opens at 20 into a housing 22 of the valve 14 . A spring-loaded check valve 26 is provided, connecting the inlet 20 to a passage 24 . The non-return valve normally closes off a passage 28 to the hydraulic motor 10 .

[0013] A spool 30 is movably disposed in the axial bore of the housing 22 . It has a valve section 32 which cooperates in a sealing manner with an associated sealing edge in the bore of the housing 22 when it is pressed into the closed position by me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com