High-strength heat-resistant steel submerged arc welding wire

A technology of submerged arc welding wire and heat-resistant steel, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of complex composition design, increased smelting difficulty, heat resistance, etc., and achieves simple and good design. Welding process performance, good high temperature resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Its composition and mass percentage of high-strength heat-resistant steel submerged arc welding wire of the present invention are:

[0028] C 0.10~0.16%,

[0029] Mn 0.60~1.10%,

[0030] Si 0.30~0.60%,

[0031] S ≤ 0.025%,

[0032] P ≤ 0.025%,

[0033] Cu≤0.35%,

[0034] Cr 1.10~1.85%,

[0035] Ni≤0.50%,

[0036] Mo 0.50~0.80%,

[0037] The balance is Fe.

[0038] Further, the preferred range of Cr is 1.30-1.80%, the preferred range of Ni is 0.30-0.50%, and the preferred range of S and P is ≤0.020%.

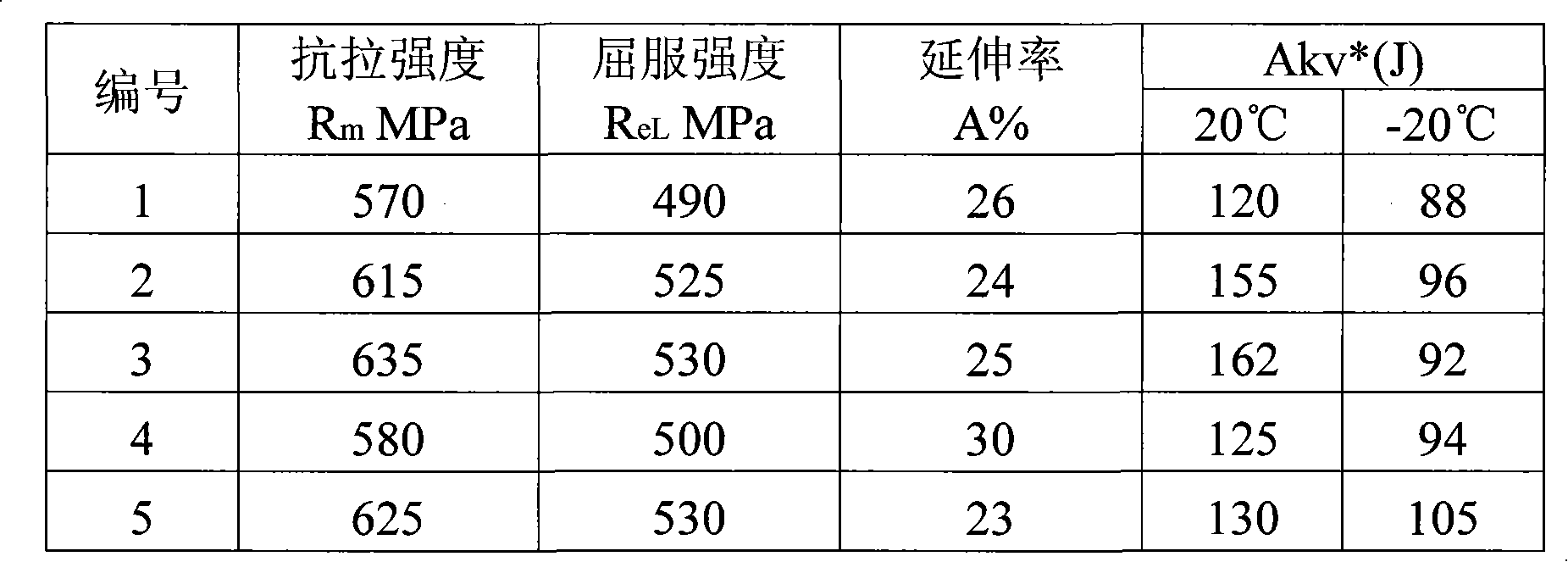

[0039] Embodiment of the present invention sees table 1

[0040] The finished product chemical composition (%) of table 1 embodiment welding wire

[0041] Numbering

C

Si

mn

Cu

Cr

Ni

Mo

S

P

1

0.11

0.31

0.62

0.30

1.10

0.15

0.51

0.010

0.010

2

0.12

0.50

0.75

0.12

1.52

0.21

0.53

0.010

0.012 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com