Suction nozzle and vacuum cleaner provided with the same

A vacuum cleaner and support device technology, applied in the direction of the suction nozzle, etc., can solve the problems affecting the mobility of the suction nozzle, and achieve the effect of increasing convenience and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] figure 1 A vacuum cleaner 1 according to the invention is shown provided with a suction nozzle 10 according to the invention which is connected to the vacuum cleaner 1 via a suction tube 2 and a flexible suction hose 3 respectively. although figure 1 A particular type of vacuum cleaner 1 is presented, in particular a canister or cylinder type vacuum cleaner, it being understood that the nozzle 10 according to the invention may be applied to any other type of vacuum cleaner, eg upright or hand-held.

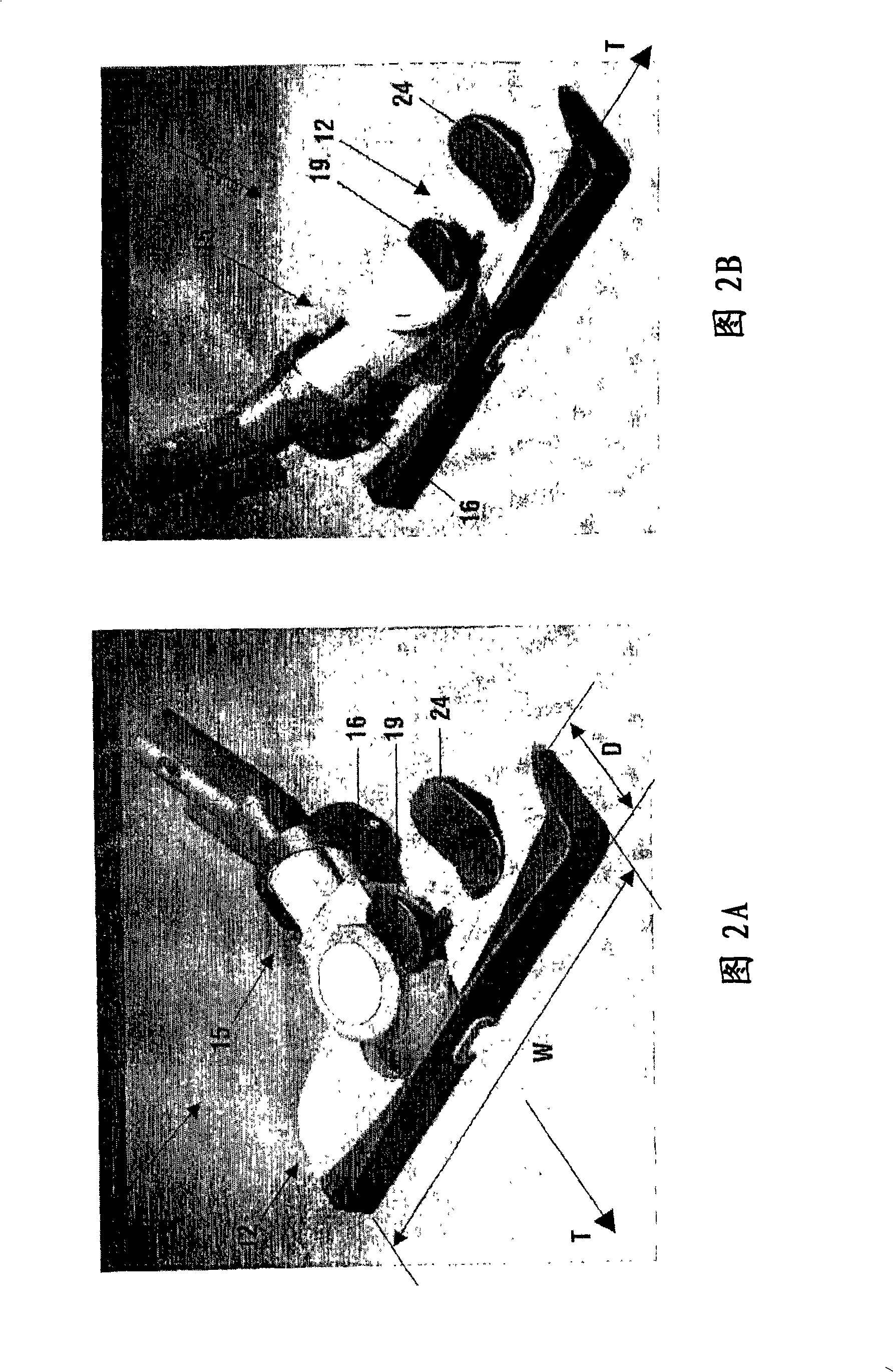

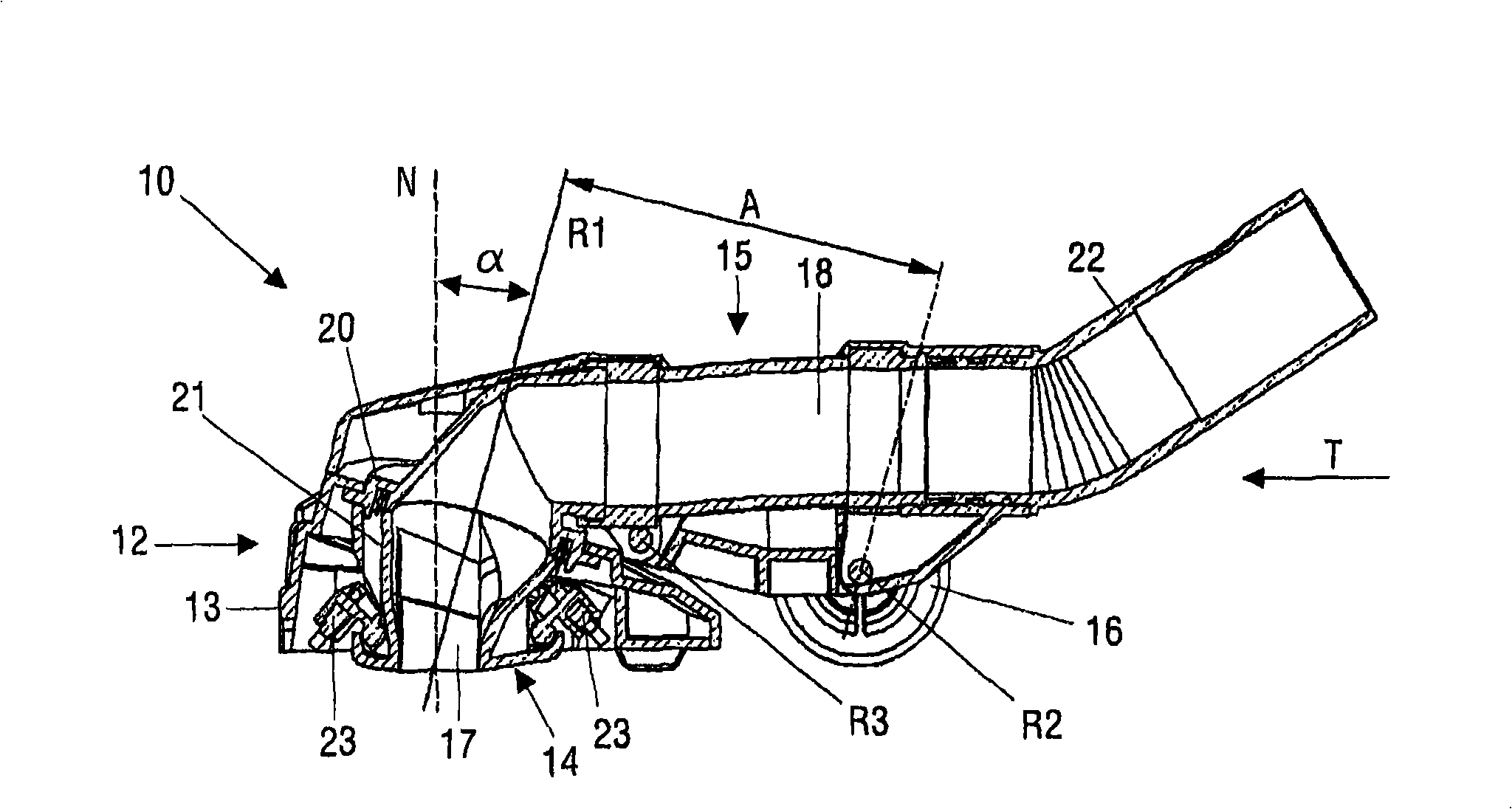

[0025] As best seen in FIGS. 2A, 2B , the suction nozzle 10 includes a suction tip 12 and an engagement body 15 . Suction head 12 includes a generally wedge-shaped housing 13 and a generally rectangular base 14 having a width W, a depth D, and a longitudinal axis L. As shown in FIG. The base plate 14 is provided with an elongated suction hole 5 extending preferably across the entire width W of the base plate 14 and terminating in a central suction channel 17 (see Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com