Cooking fume purifier

A technology of oil fume purification and oil fume purifier, which is applied in the direction of chemical instruments and methods, dispersed particle separation, separation methods, etc., to achieve the effect of eliminating pollution and quickly absorbing oil fume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

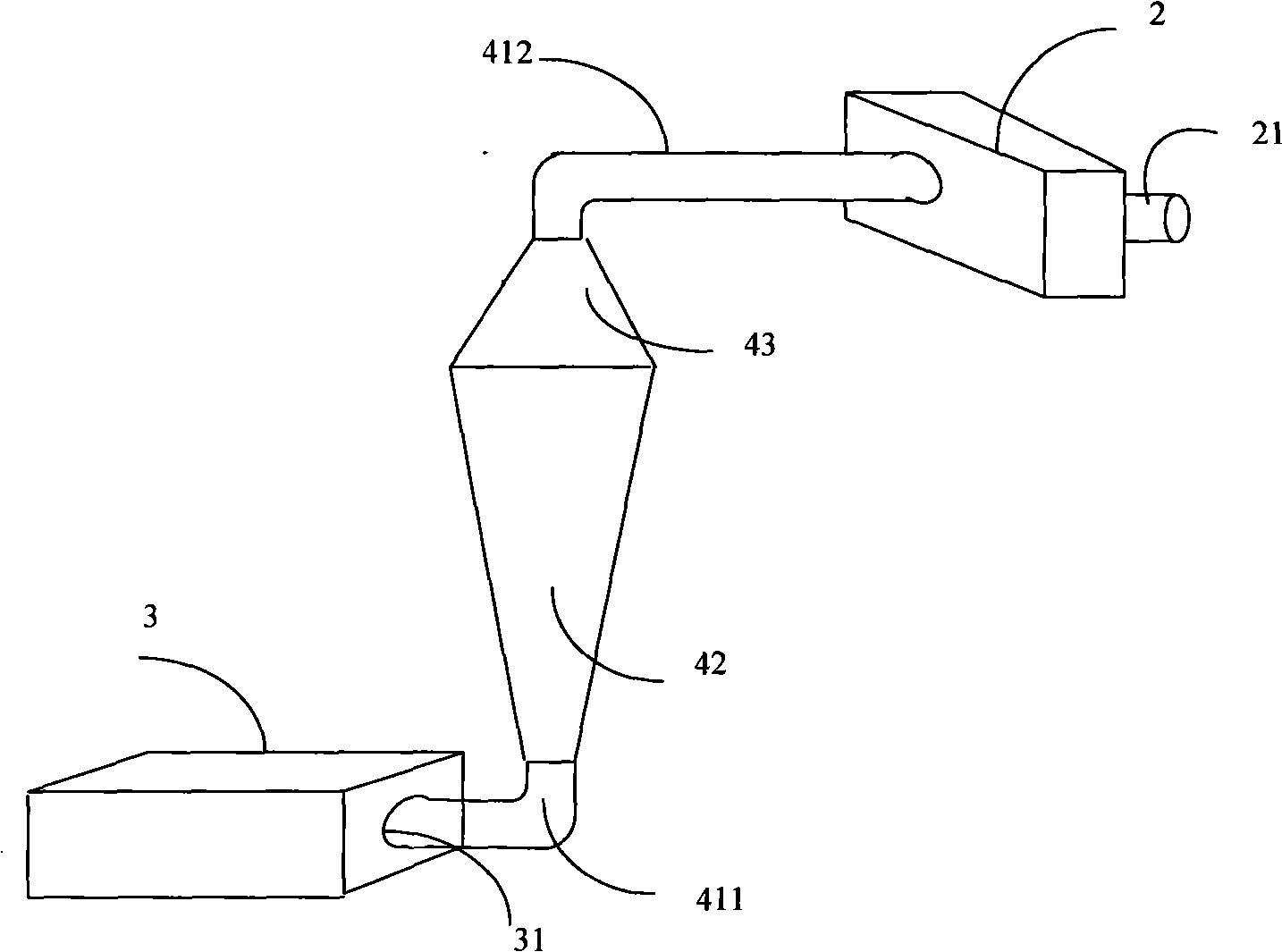

[0042] Such as figure 1 As shown, this embodiment includes a blower fan 2, which is used to generate power for sucking oil fume gas. It also includes a box-shaped oil fume collector 3, which is responsible for collecting the oil fume gas. The oil fume collector 3 is provided with an air intake hole 31, and the air intake hole 31 is connected with the air intake pipe 411 provided on the oil fume purifier. The oil fume purifier includes a conical cyclone pipe 42 , and one end of the cyclone pipe 42 with a larger diameter is buckled with a conical outlet air cover 43 . The air outlet pipe 412 is arranged on the top of the outlet air cover 43 and communicates with the inside of the outlet air cover 43 . The fan 2 is provided with an air outlet 21 .

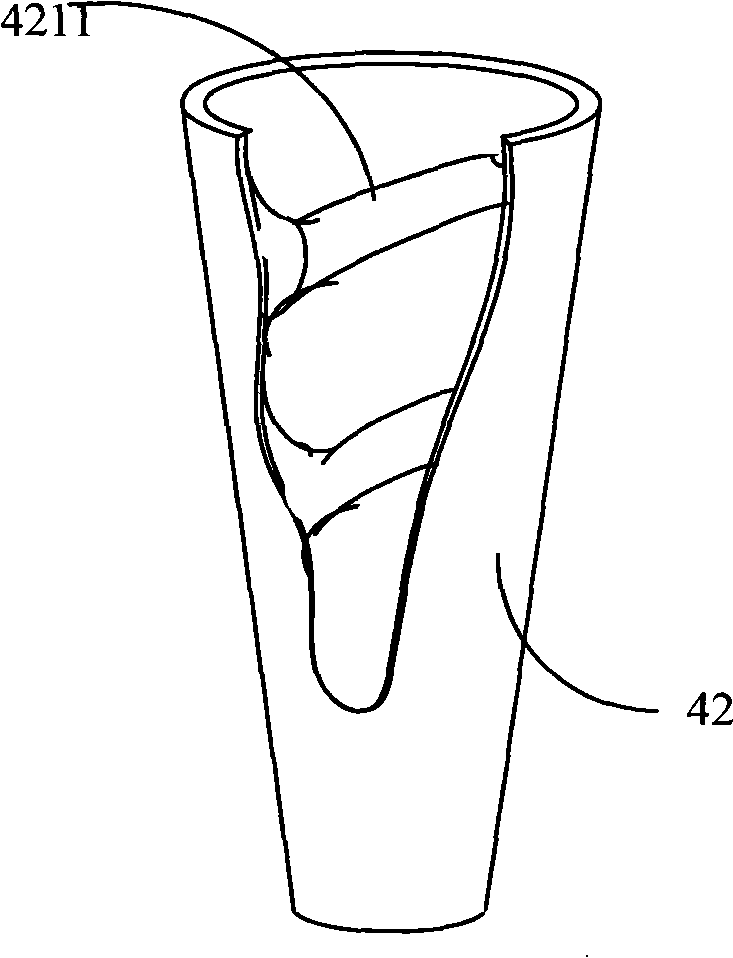

[0043] When this embodiment is working, under the action of the blower fan 2, the end of the whirlwind pipe 42 with a smaller diameter is the suction port for the fume gas collected by the fume collector. The tube wall of the cycl...

Embodiment 2

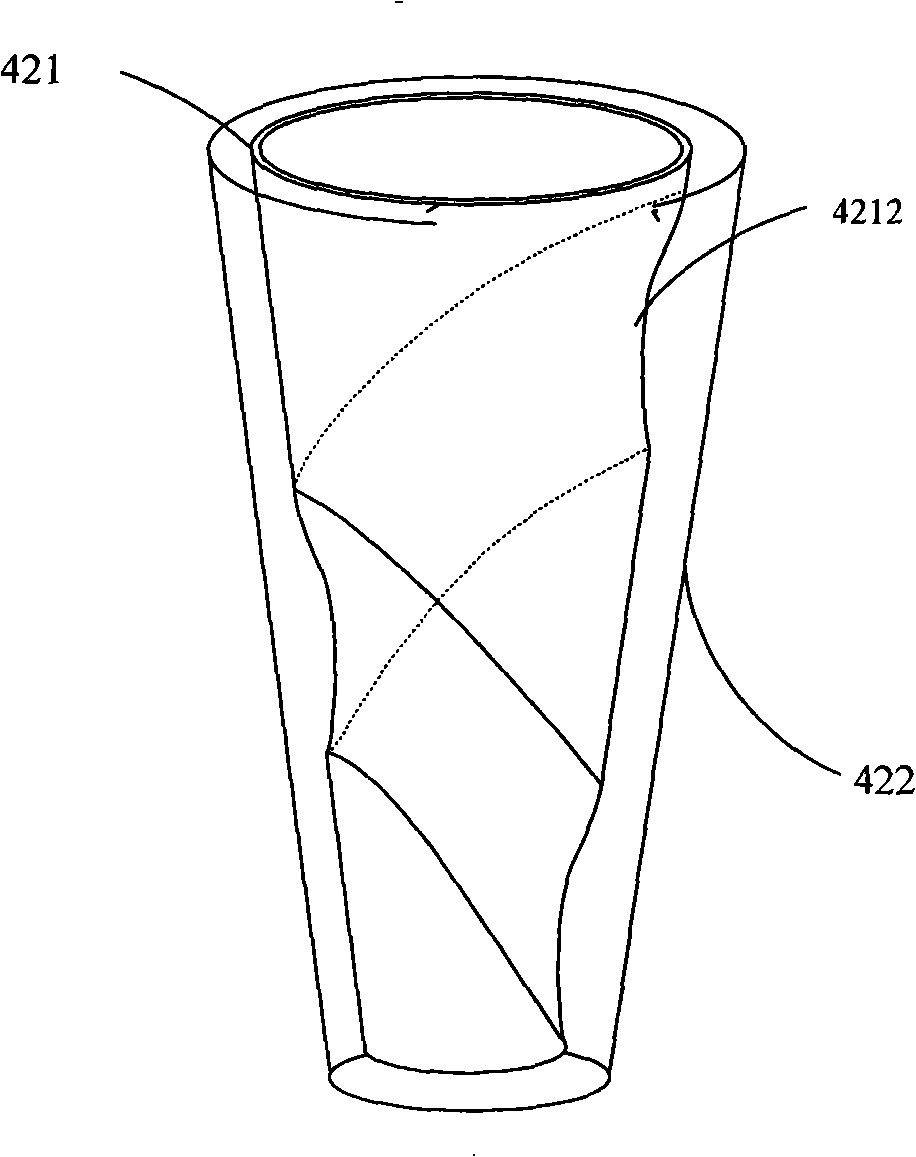

[0052] The structure of the second embodiment of the present invention is basically the same as the first embodiment, and its difference with the first embodiment is that the technical feature of the first embodiment is to utilize the centrifugal action of high-speed rotation to clean the air, and the second embodiment The technical feature is to use activated carbon and molecularly modified paint to filter and purify the peculiar smell of oil fume. Therefore, except for the differences in the internal structure of the cyclone tube 42 in the second embodiment, other points that are the same as those in the first embodiment will not be illustrated.

[0053] Such as Figure 7 As shown, in the second embodiment, the inner wall layer 421 and the outer wall layer 422 of the cyclone pipe 42 do not directly pass through the opening at the end with a larger diameter, and the inner wall layer and the outer wall layer are isolated so that they pass through the filter screen Only then c...

Embodiment 3

[0059] Such as Figure 10 As shown, this embodiment includes an axial flow fan 2 arranged in the cabinet 1, and the axial flow fan 2 is used for sucking oil fume gas. A box-shaped fume collector 3 is also provided below the cabinet 1 . The oil fume collector 3 is provided with a plurality of air intake holes 31 , and each air intake hole 31 is connected with an air pipe 411 on a oil fume purifier 4 . The oil fume purifier 4 includes a conical cyclone tube 42 , and one end of the cyclone tube 42 with a larger diameter is buckled with a frustum-shaped outlet gas cover 43 . The air pipe (outlet pipe) 412 is arranged on the top of the outlet air cover 43 and communicates with the inside of the outlet air cover 43 . In order to connect the outlet pipes 412 of multiple oil fume purifiers to the fan, a large-diameter confluence air pipe 413 is provided, on which a plurality of air inlets 22 are opened, and the air is discharged from the outlet 21 provided on the chassis 1 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com