Prestressing force steel structure rolling type stretching cable node

A prestressed steel, roll-on technology for use in suspension bridges, bridge forms, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

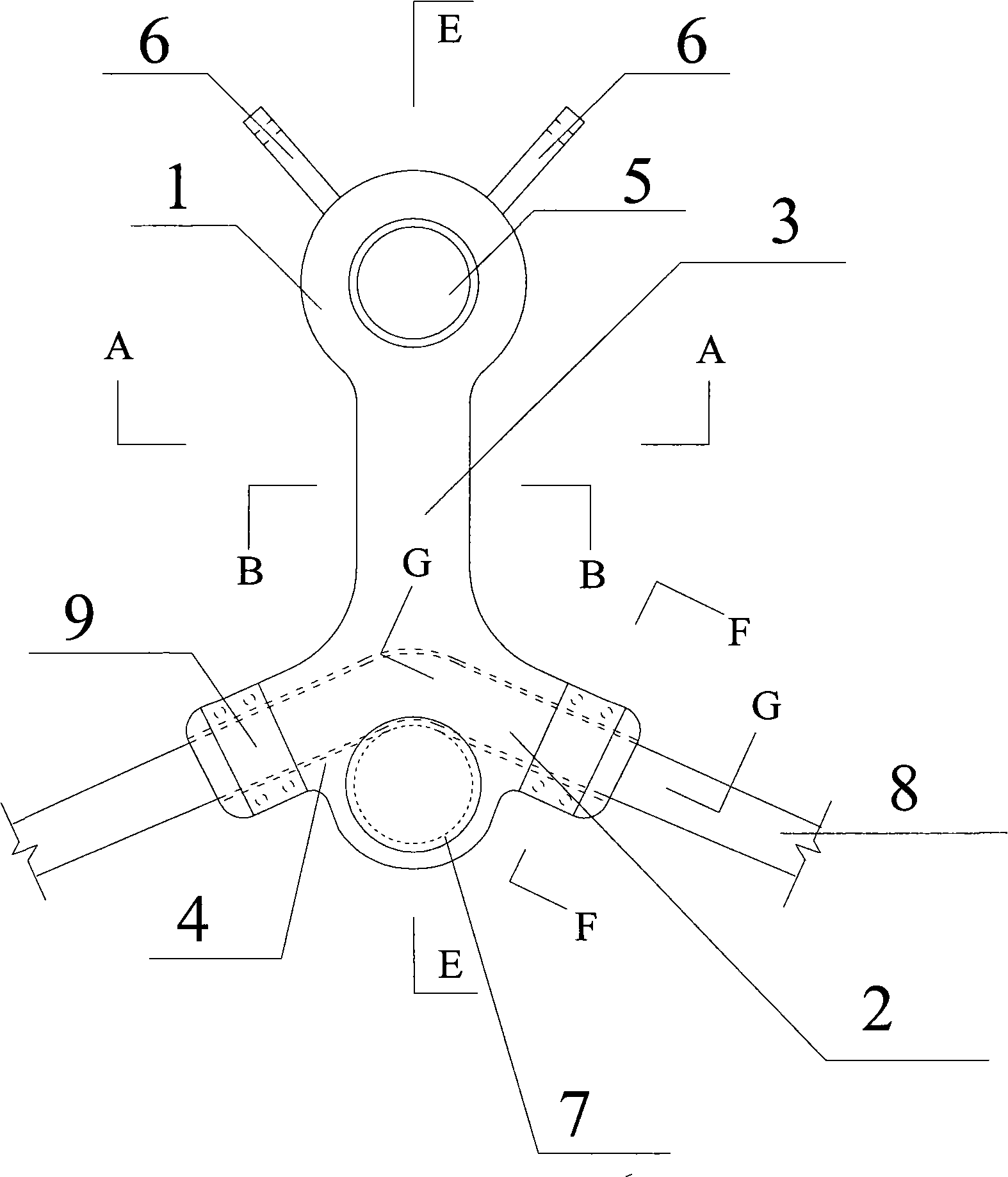

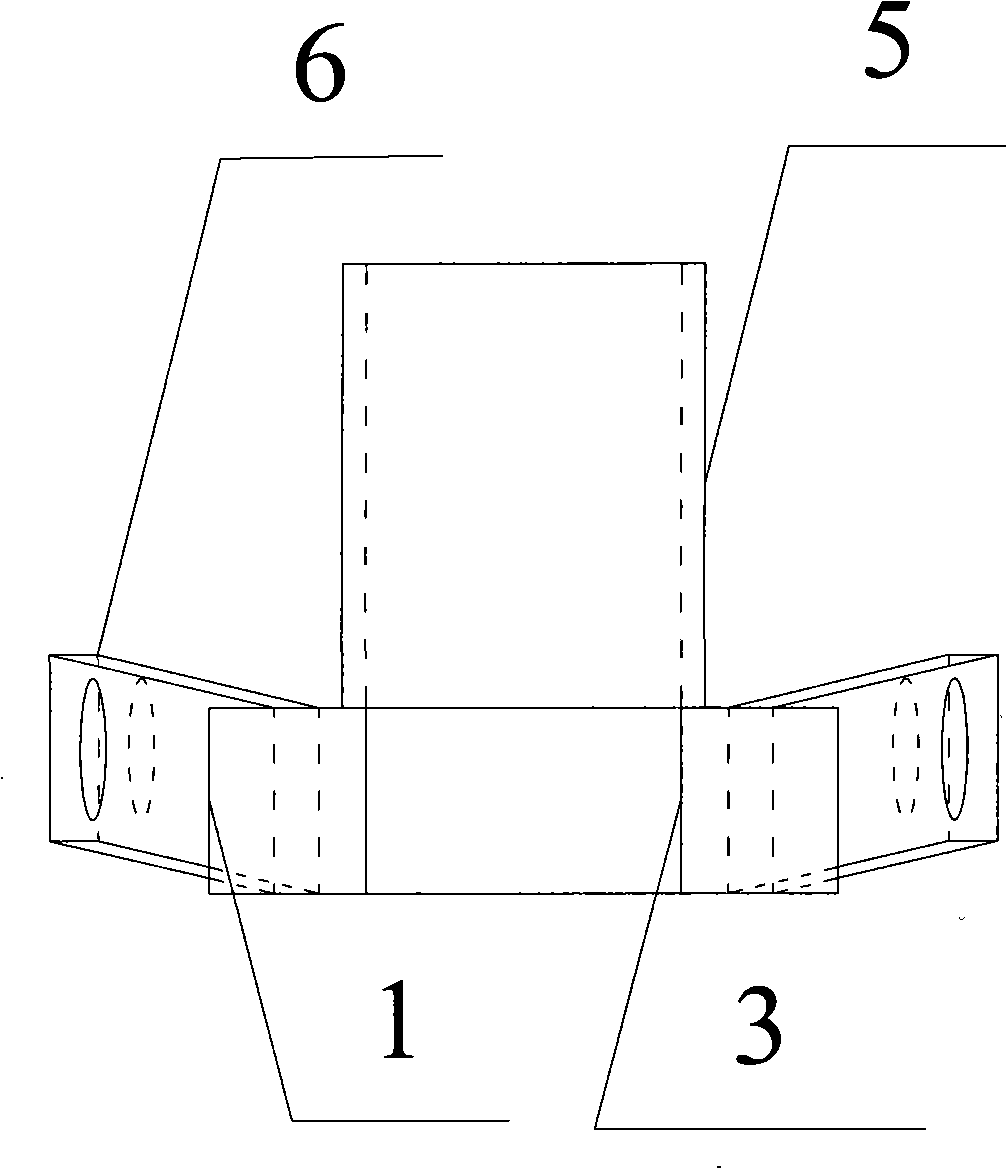

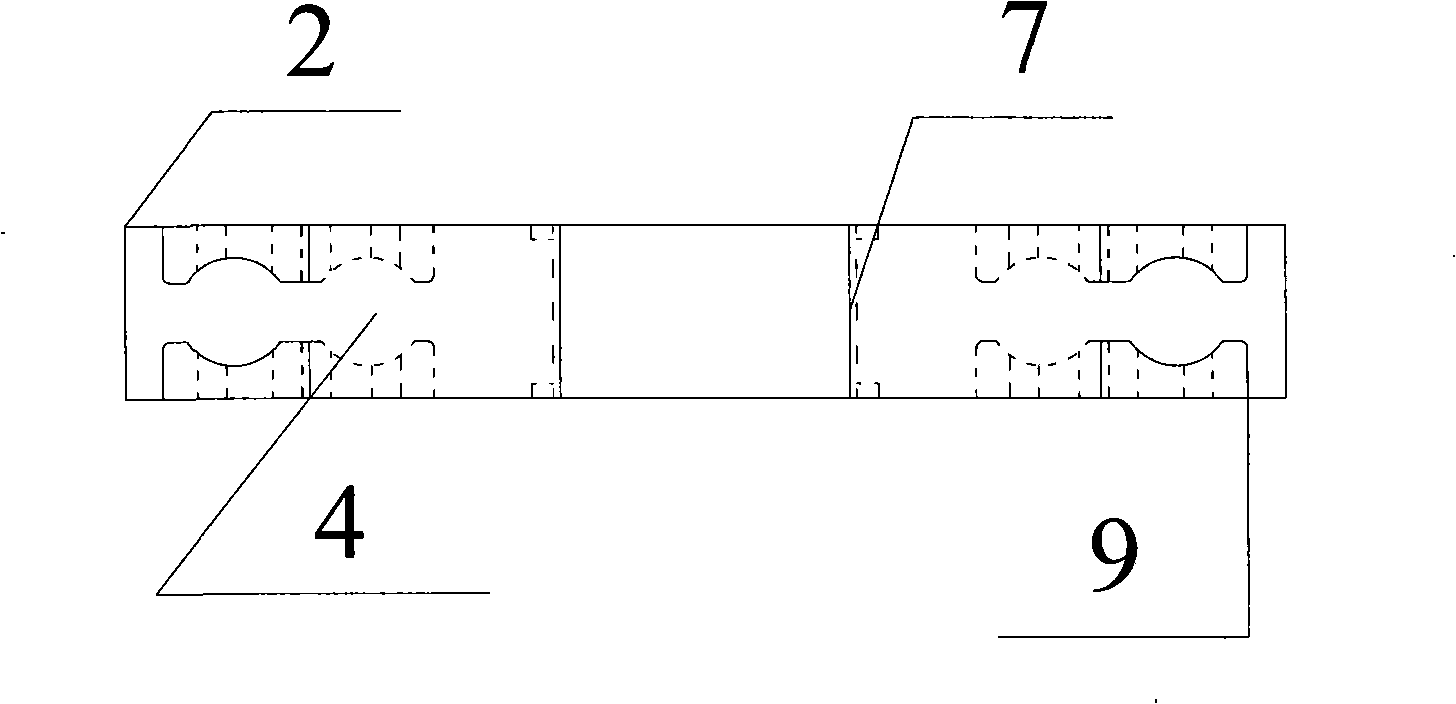

[0027] Such as figure 1 As shown, the prestressed steel structure rolling tension cable node of the present invention includes: a discontinuous cable end body 1, a continuous cable end body 2, a node waist 3, a cable cavity 4, a strut 5, an ear plate 6, and a rolling shaft 7 , continuous stay cable 8, fixed briquetting block 9. The discontinuous cable end main body 1 and the continuous end main body 2 are connected as a whole by the node waist 3; the discontinuous cable end main body 1 is provided with an ear plate 6; the strut 5 is connected to the discontinuous cable end main body 1; The cable cavity 4 is arranged on the continuous cable end main body 2 , and the continuous cable 8 passes through the continuous cable end main body 2 through the cable cavity 4 and surrounds the rolling shaft 7 , and is fixed by a fixed pressing block 9 . The discontinuous cable end main body 1, the continuous cable end main body 2 and the node waist 3 can be formed by integral casting; they ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com