Cyclone resisting vertical shaft wind motor based on vane corner control

A vertical axis and wind turbine technology, applied in the direction of wind turbines at right angles to the wind direction, wind turbines, control of wind turbines, etc., can solve the problems of reducing wind energy utilization, increasing cost, and limiting the scope of application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

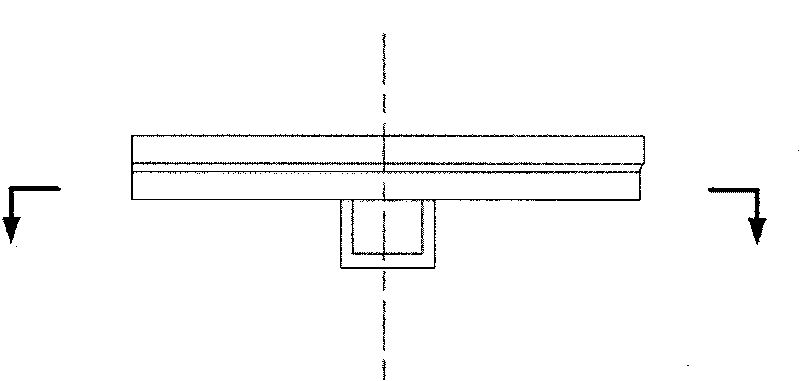

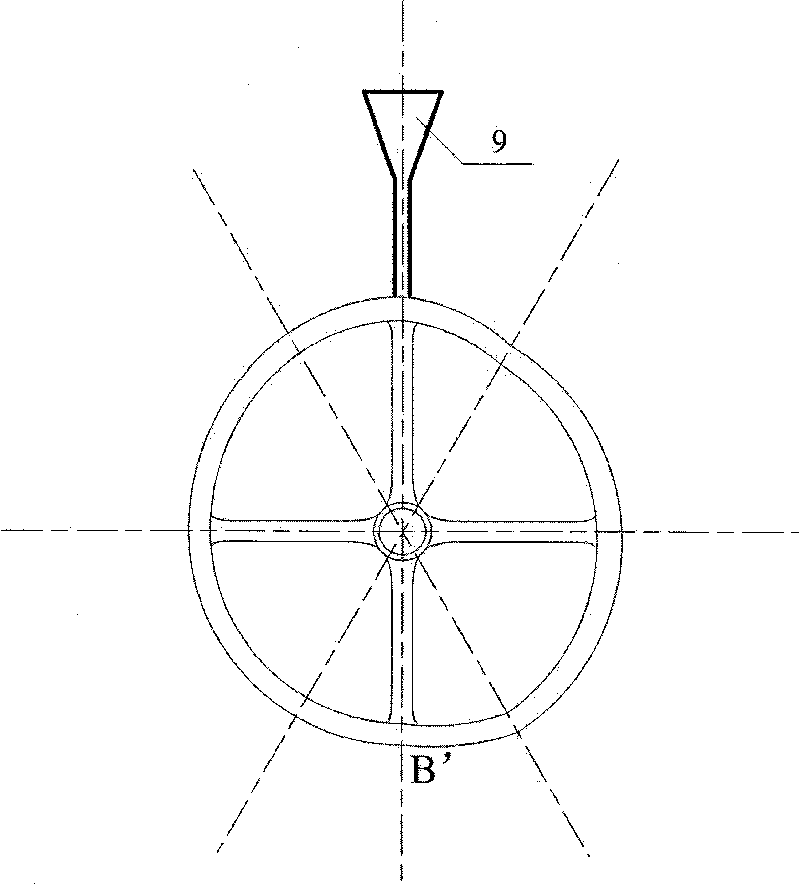

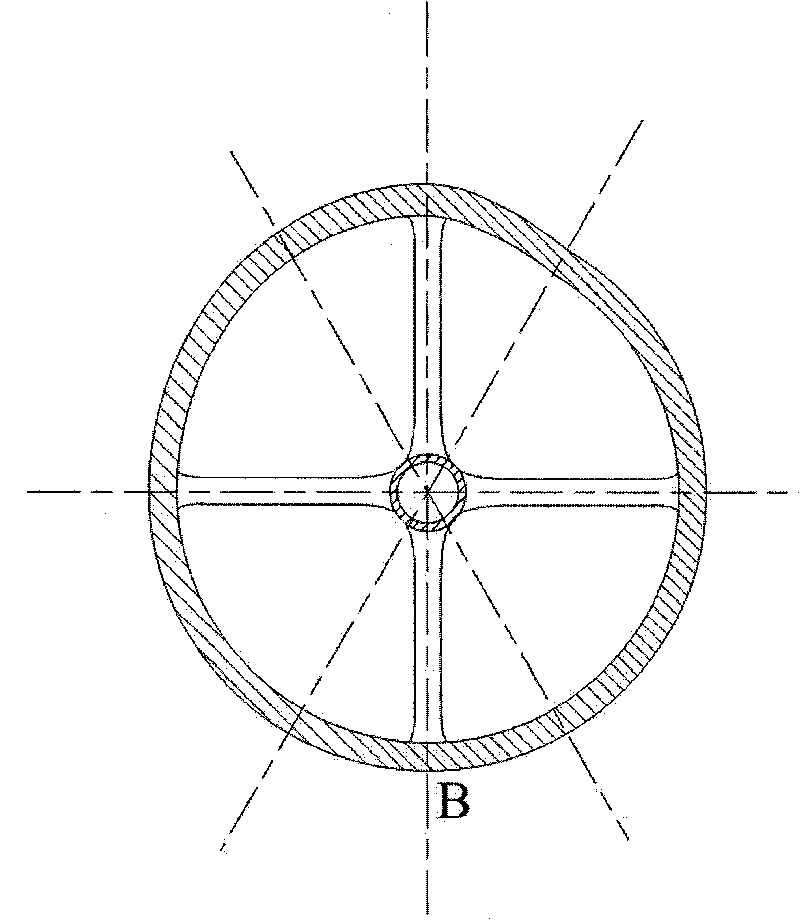

[0020] The blade of the wind turbine designed in this patent should not only be able to drive the vertical axis to rotate (that is, revolution in terms of telekinetics), but also be able to make the necessary rotation around its own axis under the action of the guide rail and the rack and pinion mechanism (that is, self-rotation). , It is also beneficial to generate as much torque as possible, so the cross-sectional shape of the blade is designed to be flat and streamlined, and the coaxial gear is fixed on the lower part. The rack and the gear mesh in the rack and pinion seat. Under the control of the cam guide rail curve, the rack is reciprocated and moved along the radial direction of the cam under the joint action of the cam guide rail and the spring, and the driving blades rotate automatically according to the working requirements of the wind turbine, making it Generate as much thrust as possible when facing the wind with a wide face, and as little thrust as possible when t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com