Wall-climbing grinding robot for steel large container

A large-scale container and robot technology, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the requirements of welding seam shape characteristics, different service conditions, grinding requirements, grinding requirements, etc. problem, to achieve the effect of fast frequency, enhanced grinding effect, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

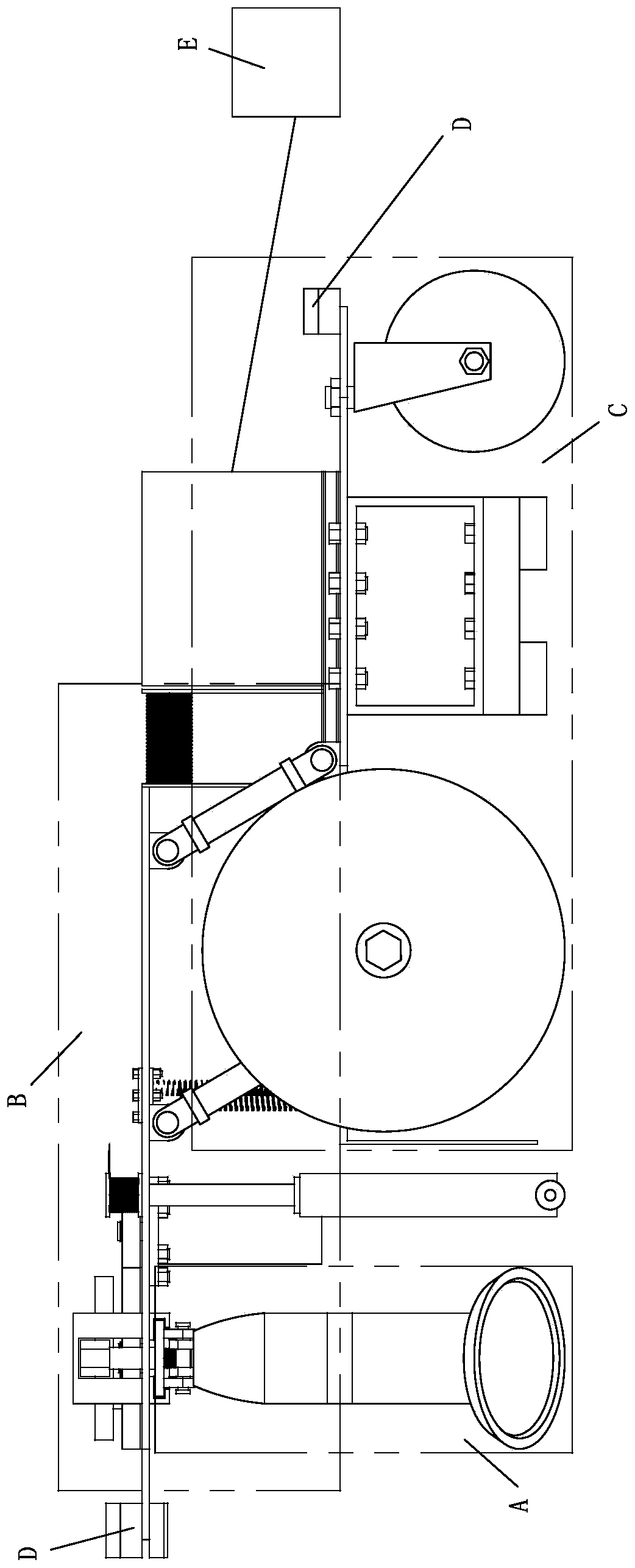

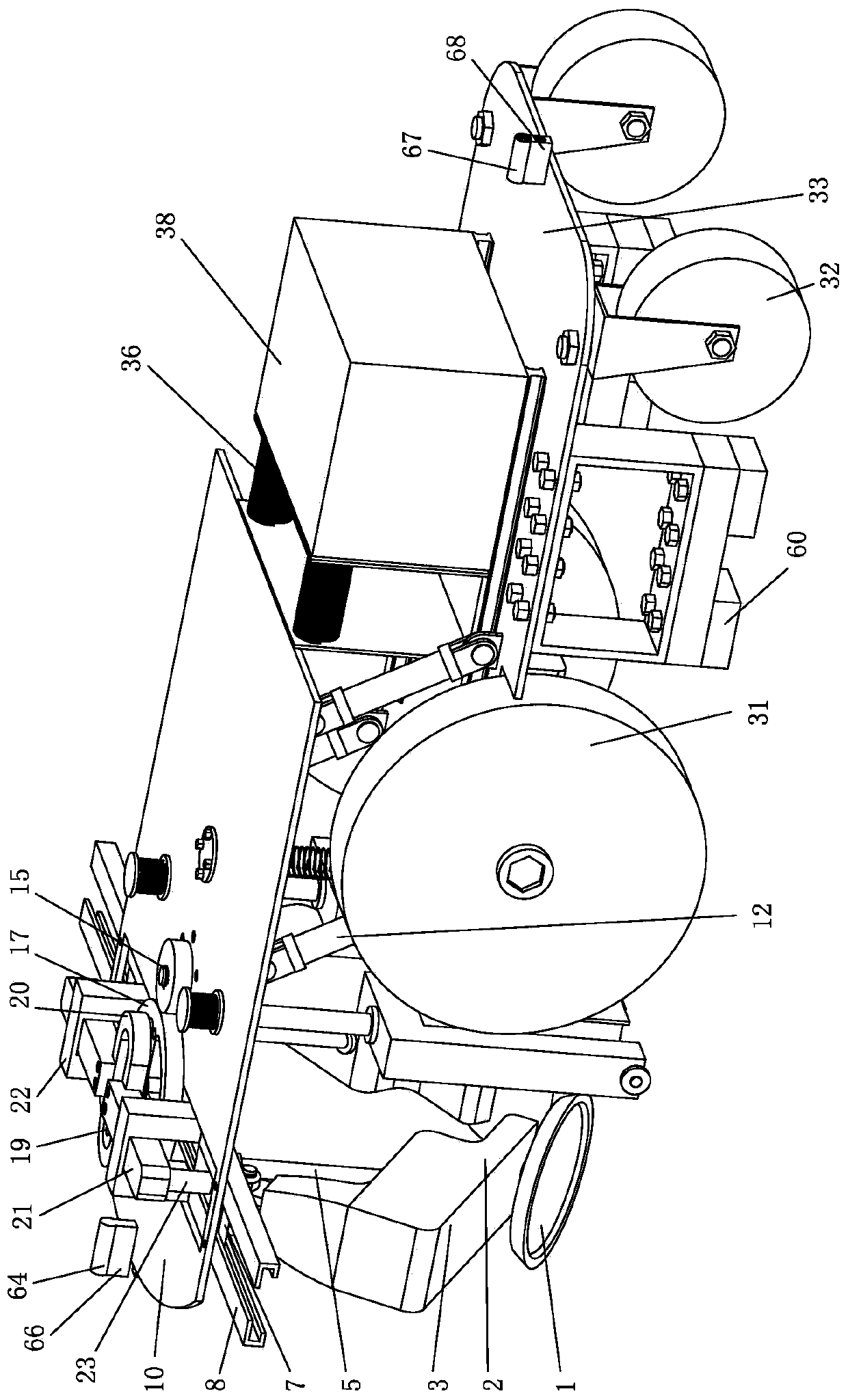

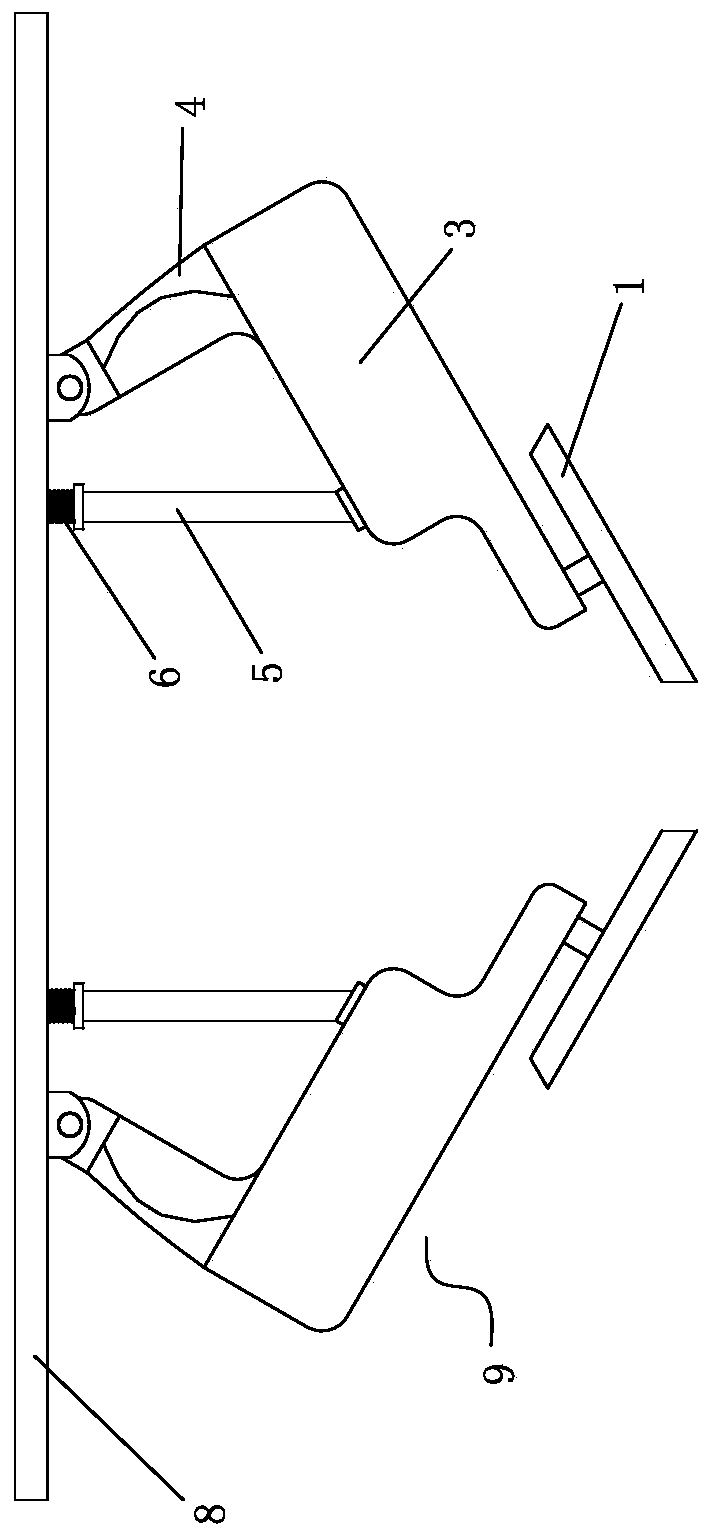

[0052] Such as figure 1 The wall-climbing grinding robot for large steel containers shown includes grinding mechanism A, grinding platform B, traveling body C, calibration and video detection system D (including calibration and front video detection system and rear video detection system) and external operations Station E grinds the wall surface F of the large steel vessel. The walking car body is used to crawl on the container wall, the grinding platform and the walking car body are hinged through several connecting rods, the grinding mechanism is installed under the grinding platform, and the calibration and front video detection system is installed at the front end of the grinding platform ( figure 1 The left side of), rear video detection system and control box 38 are installed in the traveling car body rear end. The console includes a display device f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com