Four-shaft high-speed bogie for motorcycle

A bogie and locomotive technology, applied in the field of bogies, can solve the problems of good curve passing performance, large adhesion weight, large traction capacity, etc., and achieve the effect of good curve passing performance, low wheel and rail wear, and improved traction power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

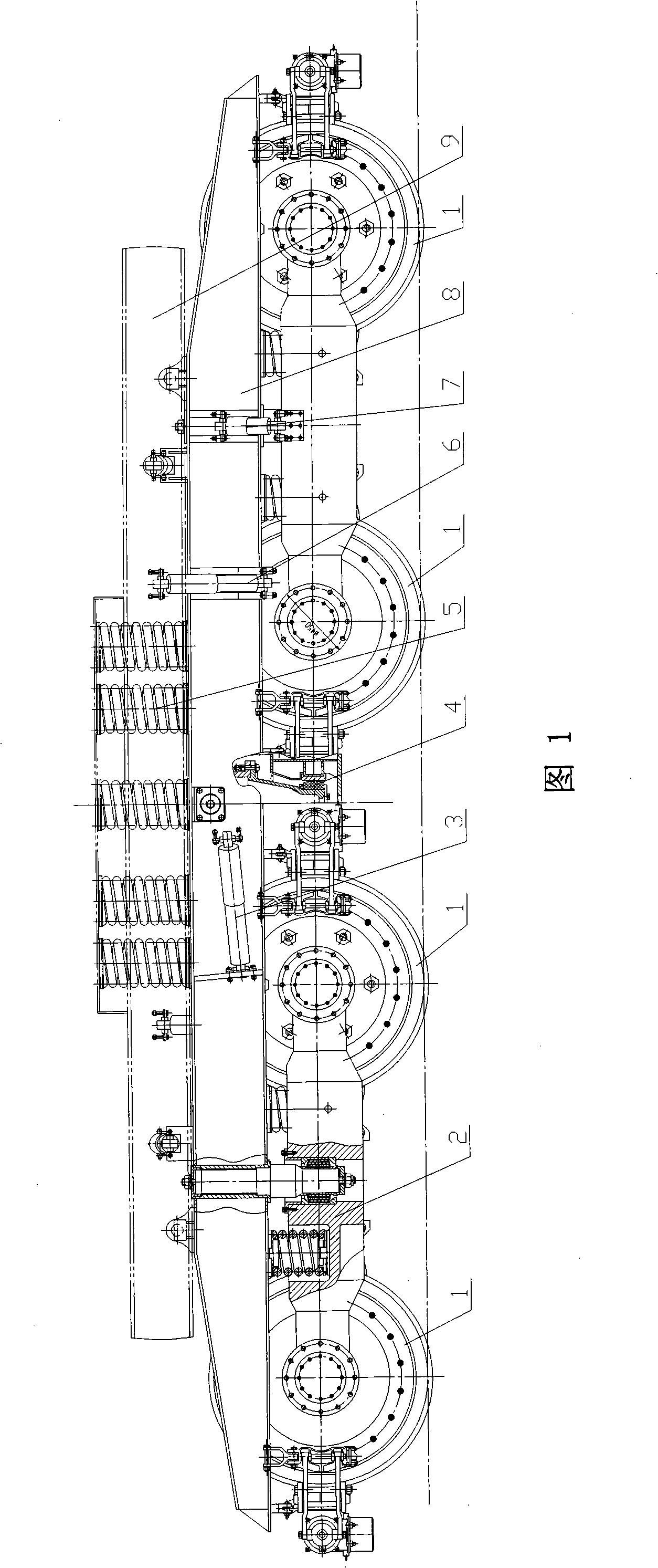

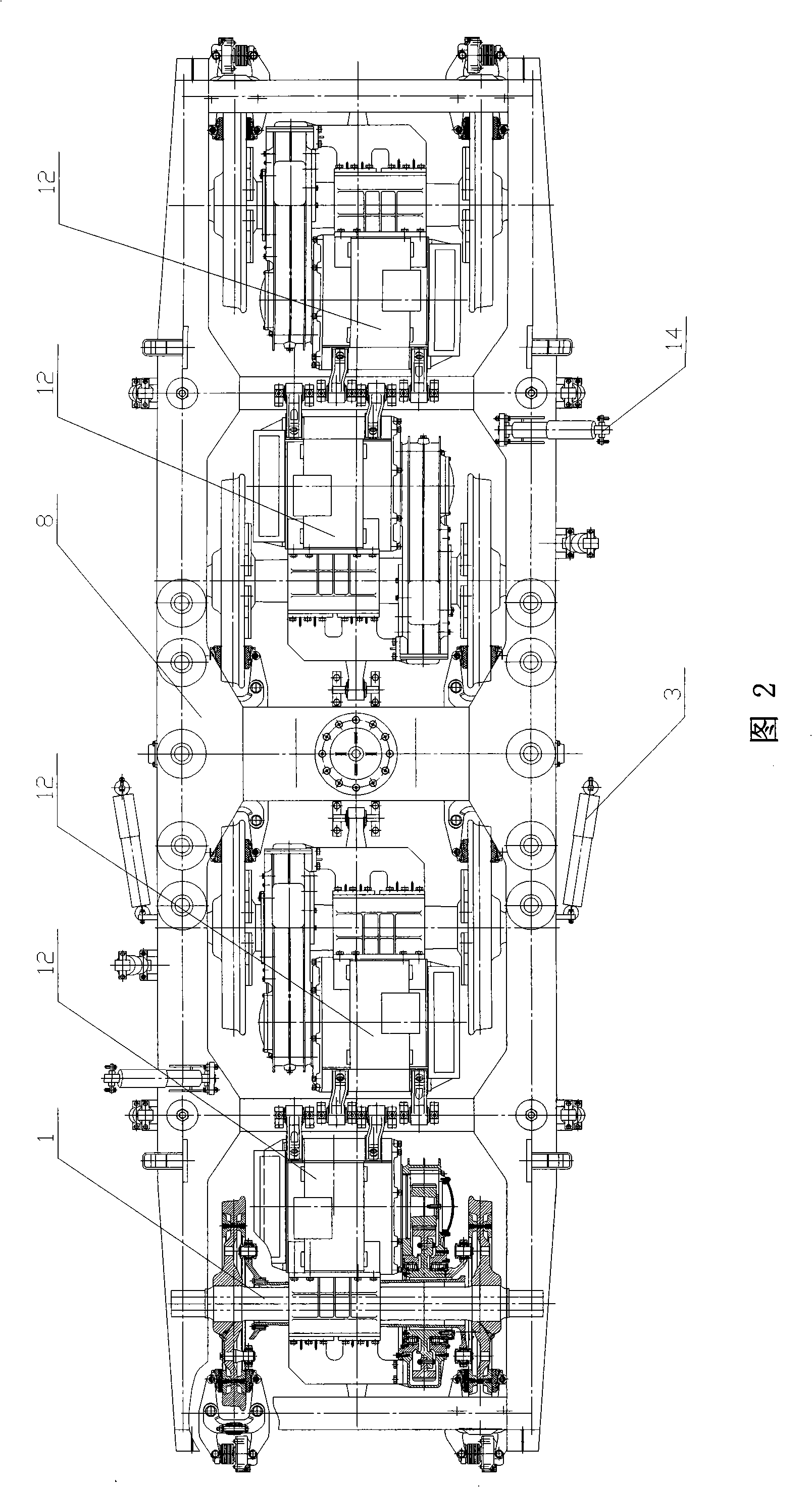

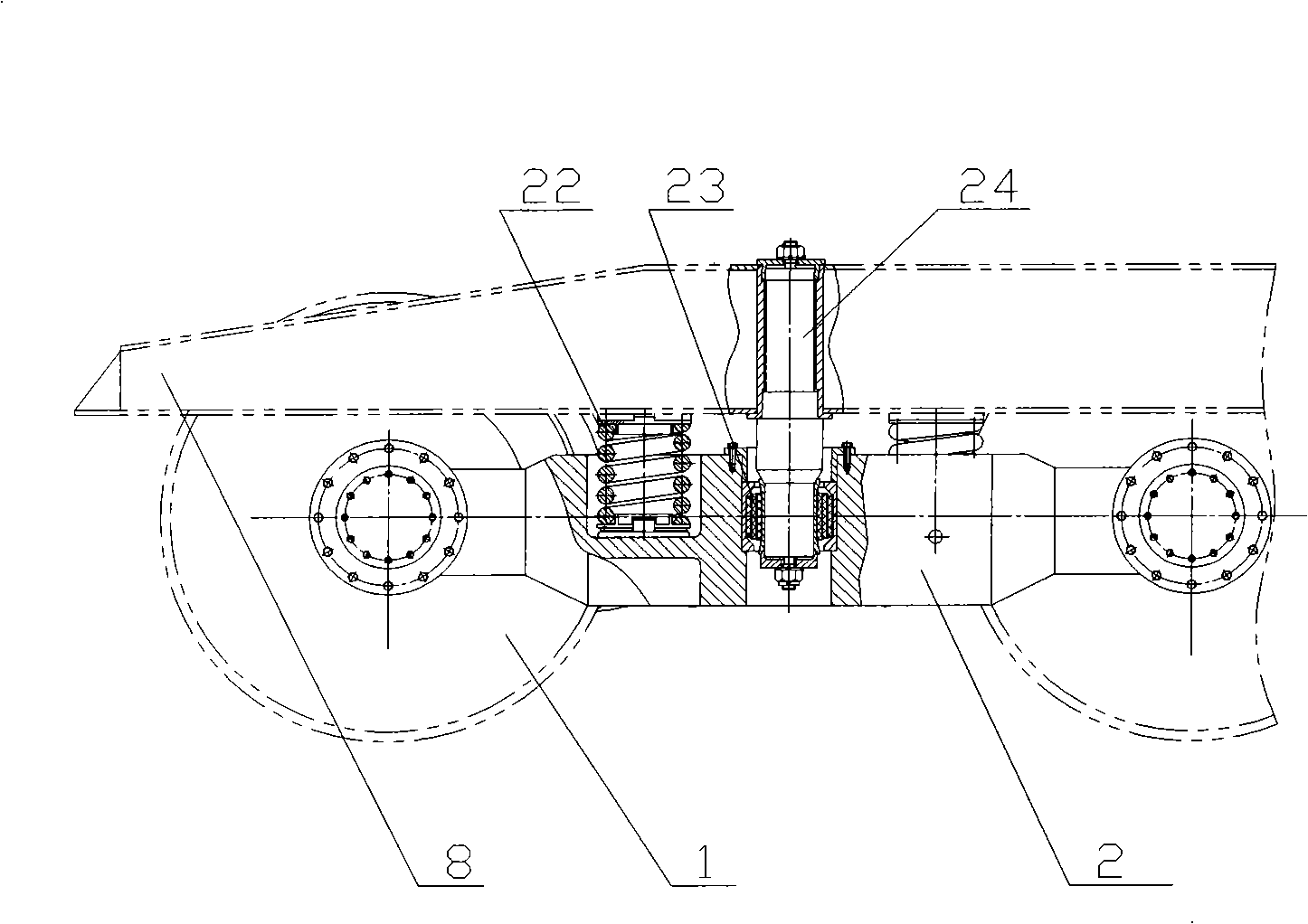

[0049] As shown in Figures 1 and 2, a four-axle high-speed bogie for locomotives of the present invention includes a frame 8 and four wheel pairs 1 mounted on the frame 8, and the wheel pairs 1 are installed on the frame 8 through a suspension mechanism. Above, each wheel pair 1 is respectively connected with the transmission mechanism and the driving device installed on the frame 8, and the four wheel pairs 1 are divided into two groups in pairs, and the two wheel pairs 1 in the same group are connected by spherical axle box bearing The equalizing beam 2 is connected, and the equalizing beam 2 is fixed on the frame 8 through the supporting shaft 24, and one or more coil springs 22 are arranged between the equalizing beam 2 and the frame 8. Each set of wheelsets 1 and the corresponding two equalizing beams 2 form a parallelogram mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com